Tired of that distracting, harsh light in offices and shops? It causes headaches and kills focus. Thoughtfully designed anti-glare downlights1 are the key to creating comfortable and productive environments.

The best anti-glare LED downlights are essential for commercial spaces because they reduce visual discomfort, prevent eye strain, and improve focus. By controlling the light output, they create a more pleasant and productive atmosphere, enhancing the overall aesthetic and perceived value of a space.

When I first started in an LED factory years ago, the focus was mostly on brightness and efficiency. Lumens per watt was the king of all metrics. But as I worked with clients on high-end projects2, I quickly learned that the quality of light is just as important as the quantity. A bright room is useless if nobody can stand to be in it for more than an hour. Glare is a subtle enemy of good design, but its impact is huge. Understanding how to defeat it is what separates an average lighting plan3 from an exceptional one. This knowledge is key to creating spaces where people feel good and can perform at their best.

Let's dive deeper into how you can achieve this.

How to reduce glare from downlights?

Struggling to fix harsh, uncomfortable lighting in your projects? This glare can ruin the ambiance and make a space feel cheap. Thankfully, specific design strategies can solve this problem effectively.

To reduce glare from downlights, you should use fixtures with deeply recessed light sources, dark or matte black baffles, and advanced optics like lenses or honeycomb louvers. Choosing downlights with a low Unified Glare Rating (UGR<19) is a reliable method for ensuring visual comfort.

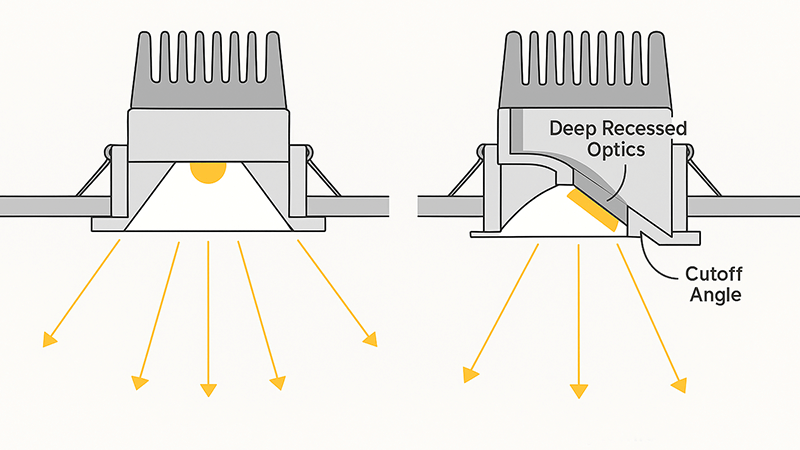

In the early days of LED downlights, the approach to glare control4 was simple: just make the downlight deeper. We called this the "brute force" method. By recessing the LED chip far up into the ceiling, you created a long, black tunnel that shielded the light source from most viewing angles. It worked, but it was inefficient and bulky. A lot of light got trapped inside the fixture itself.

I remember manufacturing these deep fixtures and thinking there had to be a smarter way. That's when the industry shifted toward precision optical engineering5. Instead of just hiding the light source, we learned to control it. Modern anti-glare downlights use sophisticated lenses and reflectors to precisely shape the light beam. These components direct the light exactly where it's needed—on the floor or a work surface—and create a sharp cutoff angle. Above this angle, very little light is emitted, so it never reaches your eyes directly. This evolution is a game-changer. It allows for smaller, more efficient fixtures while providing even better glare control.

| Glare Control Method | Description | Pros | Cons |

|---|---|---|---|

| Deep Recess ("Brute Force") | The LED chip is placed far up inside the fixture housing. | Simple design, somewhat effective. | Bulky, inefficient, traps light. |

| Black Baffle | The inner cone of the fixture is painted matte black. | Absorbs stray light, enhances contrast. | Can slightly reduce light output. |

| Precision Optics (Modern) | Custom-engineered lenses & reflectors shape the beam. | Highly efficient, excellent glare control, compact size. | More complex to design and manufacture. |

This move from brute force to precision engineering is what defines high-quality lighting today. It’s about being smarter with every single lumen.

What is an anti-glare downlight?

The term "anti-glare" gets thrown around a lot. Choosing the wrong fixture based on a vague claim can be a costly mistake for your project, so understanding its true meaning is vital.

An anti-glare downlight is a luminaire specifically engineered to shield the bright LED light source from direct view. It uses design features like a recessed lamp position, specialized reflectors, and protective lenses to minimize visual discomfort and create a softer, more pleasant lighting experience.

When we talk about anti-glare, we often reference technical specs like the Unified Glare Rating (UGR)6. A UGR below 19 is considered good for office environments. But in my experience, the true goal of anti-glare lighting goes beyond a number. It's about achieving what I call a "quiet ceiling."

Imagine you walk into a luxury hotel lobby or a high-end boutique. You notice the beautiful architecture, the well-lit displays, and the comfortable atmosphere. What you probably don't notice is the ceiling. The light sources are invisible, hidden. The ceiling is "quiet." It’s not screaming for attention with dozens of bright, distracting spots of light. This is the ultimate goal of anti-glare design. It creates a psychological sense of calm and premium quality. The light is doing its job perfectly without announcing its presence. A ceiling full of glary, "hotspot" downlights, on the other hand, makes a space feel busy, cheap, and uncomfortable. I worked on a project for a corporate headquarters where the architect's main request was to make the lighting "disappear." By using downlights with excellent optical control, we created a beautifully illuminated space where the focus was entirely on the work and the design, not on the ceiling. That's the power of a quiet ceiling.

What are anti-glare LED lights?

Faced with thousands of LED lighting products, it's easy to feel overwhelmed. Not all LEDs are created equal when it comes to visual comfort. The key is to look for anti-glare design principles.

Anti-glare LED lights are any lighting fixtures—including downlights, track lights, or linear pendants—that incorporate specific designs to control brightness and reduce visual stress. This is achieved through shielded light sources, lenses, louvers, or indirect lighting techniques to improve comfort.

One of the most important things to understand about anti-glare technology is what I call the "Efficacy vs. Comfort Paradox7." When a client asks for the most efficient light possible, they often mean the one with the highest lumens per watt (lm/W). However, achieving maximum efficiency and achieving maximum comfort are often conflicting goals. Creating excellent anti-glare requires a deliberate sacrifice of some efficacy.

Why? Think of it this way. A bare LED chip is extremely efficient at turning electricity into light, but it’s also blindingly bright. To control that glare, we have to add things like deep baffles, lenses, and reflectors. Each of these components that shields, redirects, or softens the light inevitably absorbs a small percentage of it. So, a downlight with a UGR of 15 will almost always have a lower lm/W rating than a basic, glary downlight with a UGR of 25. This is a purposeful trade-off. We are trading a little bit of raw output for a huge gain in visual quality and comfort. For commercial spaces8 like offices, where people spend eight hours a day, this is not just a good trade-off; it's an essential one. Investing in the quality of light is an investment in people's well-being and productivity.

| Feature | High Efficacy Focus | High Comfort (Anti-Glare) Focus |

|---|---|---|

| Primary Goal | Maximize lumens per watt (lm/W). | Minimize UGR and visual stress. |

| Light Source | Exposed or minimally shielded. | Deeply recessed and shielded. |

| Optics | Simple, clear cover. | Complex lenses, baffles, louvers. |

| Result | High brightness, potential for high glare. | Controlled light, "quiet ceiling," lower lm/W. |

What is the rule of thumb for downlights?

You're planning a layout, but you're not sure how to space your downlights. Getting it wrong can lead to a terrible result, with ugly dark spots or overwhelming glare from lights placed too close together.

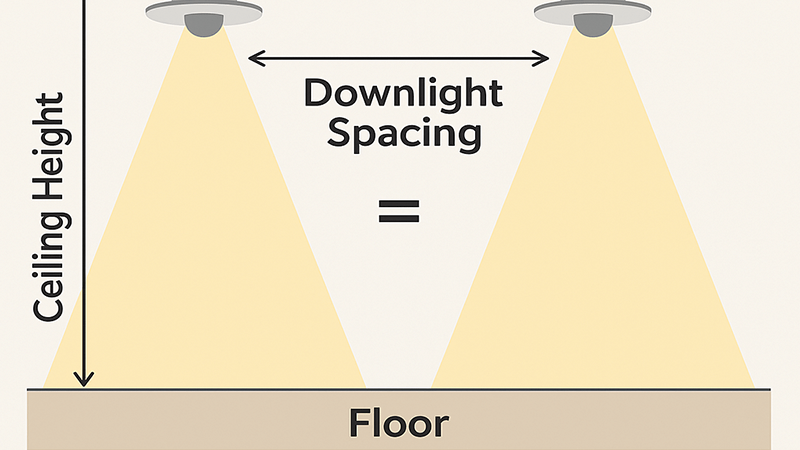

A common rule of thumb for downlight spacing is to divide the ceiling height by two. For a standard 2.7-meter (9-foot) ceiling, you would space the downlights about 1.35 meters (4.5 feet) apart. This is a starting point and should be adjusted based on the light's beam angle.

This spacing rule is a great starting point for a general layout. But for a truly professional result, especially with anti-glare fixtures, there's a more critical factor at play: manufacturing consistency9. I call this the "Tyranny of Tolerance." You can have the perfect lighting plan, with perfect spacing, but if the downlights themselves are inconsistent, the entire project can be ruined.

I’ve seen this happen. A contractor buys a batch of downlights from a cheap supplier. Once installed, some of the lights look slightly warmer, others slightly cooler. A few have a slightly wider beam angle than the others. The result is a messy, uneven ceiling that completely undermines the "quiet ceiling" effect. This is where quality manufacturing becomes the unsung hero of anti-glare lighting. At my factory, we enforce incredibly strict tolerances. We use LEDs from the same bin, ensuring identical color temperature across the entire batch (e.g., within a 3-step MacAdam ellipse). We use precision molds and automated assembly to ensure every single lens and reflector is aligned perfectly. This guarantees that the 1st and the 1000th downlight in an order perform exactly the same. For a purchasing manager like Shaz, this consistency is non-negotiable. It means you can trust that the design on paper will become a reality, without any unpleasant surprises during installation.

Conclusion

Ultimately, anti-glare lighting is a crucial choice, not an accident. It involves trading some raw efficiency for superior comfort and relies on quality engineering and strict manufacturing consistency to succeed.

Explore how anti-glare downlights enhance comfort and productivity in work environments. ↩

Learn what sets high-end lighting projects apart in terms of design and quality. ↩

Explore the essential elements that contribute to a successful lighting design. ↩

Investigate various strategies for controlling glare in commercial lighting. ↩

Find out how precision engineering enhances lighting quality and efficiency. ↩

Understand the significance of UGR in selecting lighting for comfortable spaces. ↩

Discover the trade-offs between lighting efficiency and visual comfort. ↩

Explore effective lighting solutions tailored for commercial environments. ↩

Learn how consistency in manufacturing affects lighting quality and performance. ↩