Worried about fire risks in your lighting projects? A single non-compliant downlight can lead to disaster. Let’s clarify what fire-rated means for your safety and peace of mind.

Yes, you need fire-rated downlights when installing them in a fire-rated ceiling, such as the floor between stories of a building. They are legally required in these situations to maintain the ceiling's integrity and slow the spread of fire and smoke between floors.

So, you know you need them for certain ceilings. But that's just the start. The term "fire-rated" can be misleading, and understanding the real mechanics of fire safety1y in LEDs](https://www.wired4signsusa.com/blogs/led-technical-blog/are-led-strips-safe-and-can-they-cause-fires)%%%FOOTNOTE_REF_2%%% is crucial for any professional. I've learned from years in the factory that the real danger often isn't what you think. Let's dig deeper into what a fire-rated downlight really does and where you absolutely must use them.

Are Fire-Rated Downlights Really Necessary?

Building regulations are strict for a reason. Ignoring fire-rated requirements3 isn't just a compliance issue; it’s a serious safety gamble. I'll explain why they are absolutely essential.

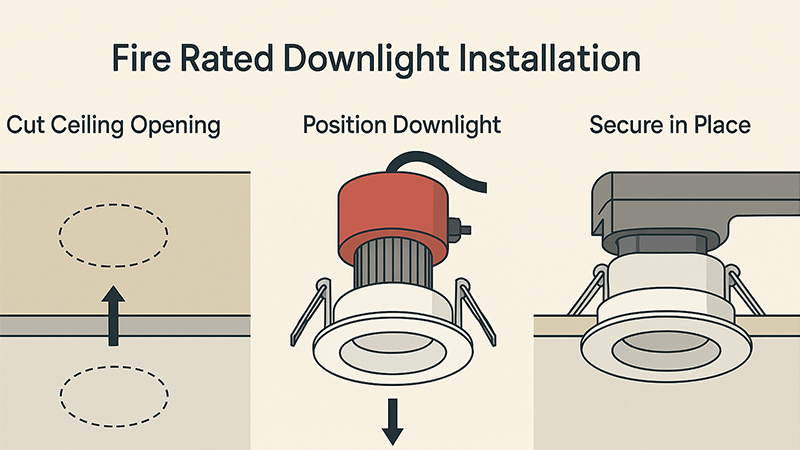

Yes, they are necessary to preserve the fire barrier of a ceiling or wall. When you cut a hole for a downlight, you create a weak point. A fire-rated downlight is designed to seal that hole in a fire, stopping flames and smoke from passing through.

When I first started in this industry, I thought of fire safety in simple terms. But seeing the manufacturing process up close taught me a critical lesson. A fire-rated ceiling4 is a system. It's designed to hold back a fire for a specific period, maybe 30, 60, or 90 minutes. This gives people time to escape and for firefighters to arrive. Every time you cut a hole in that ceiling to install a downlight, you break that system. You've created a direct pathway for fire to bypass the barrier.

A fire-rated downlight is built to fix this problem. The key component is an intumescent material5. When this material gets hot, it expands rapidly—sometimes up to 50 times its original size. This expansion completely seals the hole where the downlight is, restoring the ceiling's fire-resistant properties. It effectively plugs the gap. Without this feature, a fire could race through the ceiling void and engulf an upper floor in minutes. So, when we talk about necessity, it’s not just about following rules. It’s about protecting property and, more importantly, saving lives. This isn't a feature you can compromise on.

Where Are Fire-Rated Lights Required?

Confused about where you must install fire-rated lights6? It's a common question with very clear answers. Getting this wrong can lead to failed inspections and costly rework.

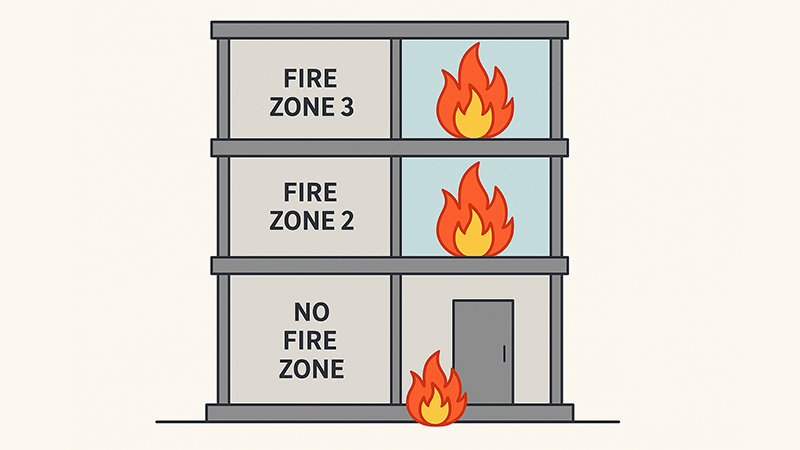

Fire-rated lights are required in any ceiling that acts as a fire barrier between two separate living spaces or zones. This primarily includes the ceilings between floors in a multi-story home or apartment building. They are also needed in ceilings below an occupied attic or roof space.

The rules are quite logical once you understand the principle of 'fire separation7'. The goal is to contain a fire in the room where it starts for as long as possible. Let me give you a clear breakdown of where these regulations typically apply.

Key Locations for Fire-Rated Downlights

- Ceilings Between Habitable Floors: This is the most common requirement. The ceiling of your first floor is the floor of your second floor. If you install downlights in that first-floor ceiling, they must be fire-rated to protect the people upstairs. This applies to family homes, apartment blocks, and hotels.

- Integrated Garages: The ceiling between an integrated garage and the living space above it must be a fire barrier8. Car fires are intense, so this is a critical safety feature. All downlights installed here must be fire-rated.

- Ceilings Below Loft Conversions: If you have a room in the attic or loft, the ceiling of the floor below it must be fire-rated. This protects the escape route for anyone in the converted space.

- Commercial Buildings: In commercial settings like offices or retail stores, fire separation rules are even more stringent. They are used to create fire-protected escape corridors and to separate different business units within the same building.

I remember a client, Shaz from the UAE, who was sourcing for a large residential tower. He was meticulous about specifications. He knew that for his project, every single downlight in the apartment ceilings had to be 90-minute fire-rated. For him, it wasn't just a line item; it was a non-negotiable part of the building's life safety system. That's the professional mindset you need.

What Does Non Fire Rated Downlight Mean?

Choosing a non-fire-rated light for the wrong place is a big mistake. The cost savings are tiny compared to the risk. Let's clarify what these products are and are not.

A non-fire-rated downlight is a standard light fixture that offers no protection against the spread of fire. It has no special materials or construction to seal the hole it occupies in a fire, making it unsuitable for use in fire-rated ceilings.

A non-fire-rated downlight9 is simply a metal or plastic housing for a bulb or LED module. Its only job is to hold the light source and connect to the power. It has absolutely no fire-stopping capabilities. If you install one in a fire-rated ceiling and a fire breaks out, the heat will melt the plastic components and create an open hole. Flames, heat, and toxic smoke will pour straight through that opening into the space above. Think of it as leaving a window open for the fire.

The real danger, however, is often linked to overheating, which is the root cause of many electrical fires. I've spent my career focusing on this. The real fire safety of an LED downlight, whether fire-rated or not, starts with its ability to manage heat. Here's what I've learned is most important:

| Feature | Critical for Fire Prevention | Why It Matters |

|---|---|---|

| Heat Sink | A heavy, well-designed aluminum heat sink is non-negotiable. | This is the true hero. It pulls heat away from the LED chip. Poor heat dissipation is the main cause of fire. |

| Body Material | Full metal bodies (like die-cast aluminum) are best. | Metal does not burn and it helps conduct heat away. It's the ultimate firewall against the source of ignition. |

| Plastics Type | Must use "flame retardant" plastics, not just standard plastic. | "Flame retardant" does not mean "fireproof". It means the plastic will self-extinguish when the flame is removed. |

A flimsy, lightweight downlight is a major red flag. It means the manufacturer cut corners on the heat sink10. That fixture will overheat, and over time, that heat will break down the wiring insulation, leading to a short circuit and a fire. So, even when a downlight doesn't need to be "fire-rated," it still needs to be "fire-safe" by design.

How Can I Tell if a Downlight Is Fire Rated?

You can't tell just by looking from below. A mistake here can be costly and dangerous. You need to know exactly what to look for to verify a product's rating.

A fire-rated downlight can be identified by its specific markings, certifications (like BS 476), and physical construction. It will typically be heavier and have a fully enclosed steel can or a visible intumescent band around the body of the light.

As a manufacturer, I know that true fire-rated products undergo rigorous testing and are built differently. You can't just trust a label on a box. You need to become an expert at spotting the real thing. Here are the key indicators I teach my quality control teams and clients like Shaz to look for.

The Inspection Checklist

- Check for Markings and Certifications: A genuine fire-rated downlight will have the fire rating clearly marked on the product itself, not just the packaging. Look for stamps like "30/60/90 MIN FIRE RATED" and certification marks like the British Standard BS 476-21. If there's no marking on the physical product, be very suspicious.

- Examine the Construction:

- The Can: Most fire-rated downlights have a "can" design. This means the back of the light is fully enclosed in a steel body. This steel can provides the initial containment. Non-fire-rated versions are often open-backed to save costs.

- The Weight: Pick it up. A fire-rated downlight will feel significantly heavier and more robust than a non-rated one. This weight comes from the steel can and the large aluminum heat sink, which are both essential for fire safety and performance. .

- Look for the Intumescent Seal: This is the magic ingredient. You should be able to see the intumescent material. It often looks like a thick, dark-colored band or gasket fitted around the main body of the downlight. This is the part that swells up in a fire to seal the gap. If you can't see it, it's not a fire-rated downlight.

A few years ago, a customer brought me a sample they had sourced cheaply. It was marketed as "fire-rated," but it felt light, had an open back, and there was no intumescent material. It was a fake. Using a product like that is worse than using a standard downlight because it gives a false sense of security. Always verify. Your reputation and your clients' safety depend on it.

Conclusion

In summary, use fire-rated downlights11 where legally required to maintain fire barriers. Always choose well-built fixtures with excellent heat dissipation to prevent fires from starting in the first place.

Learn best practices for fire safety to protect lives and property in residential and commercial buildings. ↩

Explore the unique fire safety considerations for LED lighting to ensure your installations are safe and compliant. ↩

Explore the specific fire-rated requirements for residential buildings to ensure safety and compliance in your projects. ↩

Learn what constitutes a fire-rated ceiling to ensure proper installation of fire-rated downlights and compliance with safety standards. ↩

Discover the science behind intumescent materials and their critical role in fire-rated downlights for safety. ↩

Find out the specific locations where fire-rated lights are mandatory to maintain safety and compliance in buildings. ↩

Understanding fire separation principles is key to designing safe buildings that can contain fires effectively. ↩

Learn about fire barriers to understand their role in fire safety and how they protect living spaces from fire spread. ↩

Understanding the differences between fire-rated and non-fire-rated downlights is crucial for making safe lighting choices. ↩

Learn about the importance of heat sinks in downlights to prevent overheating and potential fire hazards. ↩

Understanding fire-rated downlights is crucial for safety in lighting projects, ensuring compliance and protection against fire hazards. ↩