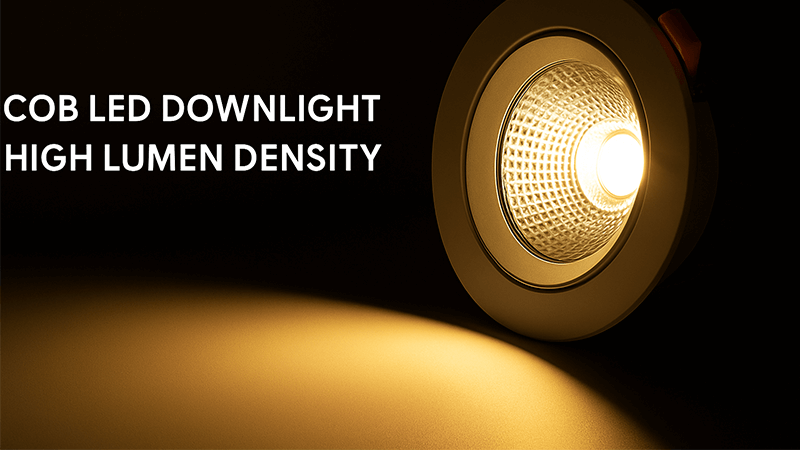

Tired of bulky downlights that lack punch? SMD models are decent but often can't deliver the intense brightness needed for your projects. COB technology offers a powerfully compact lighting solution.

COB (Chip-on-Board) downlights achieve higher lumen density by mounting multiple LED chips directly onto a single substrate. This compact design minimizes energy loss, improves thermal management, and allows for a more concentrated and powerful light output compared to individual SMD (Surface Mounted Device) chips.

That's the short answer. But as a purchasing manager like Shaz, you know the details are what really matter when making a sourcing decision. The difference between COB and SMD isn't just about brightness; it affects performance, application, and ultimately, project success. The key reason COB achieves this is through its integrated design, which simplifies the structure and optimizes heat dissipation, allowing more energy to be converted into focused light. Let's dig deeper into the technologies to understand why COB often comes out on top for lumen density and what that means for your specific needs.

Is COB LED better than SMD?

Confused about whether to choose COB or SMD for your next lighting project? The wrong choice can compromise light quality and efficiency, impacting your results. Let's clarify their differences.

Neither is universally "better"; it depends on the application. COB is better for high-lumen, focused light like in downlights and spotlights. SMD is better for distributed, wider-angle light, such as in strip lights and bulbs, offering more flexibility in color tuning.

When I first started in the lighting industry, the debate between COB and SMD was heating up. From the factory floor, I saw firsthand how each technology was assembled, and their fundamental differences became very clear. It's not about one being superior overall, but about which one is the right tool for the job. For a client like Shaz in the UAE who often handles large-scale commercial projects, this distinction is critical for both performance and budget.

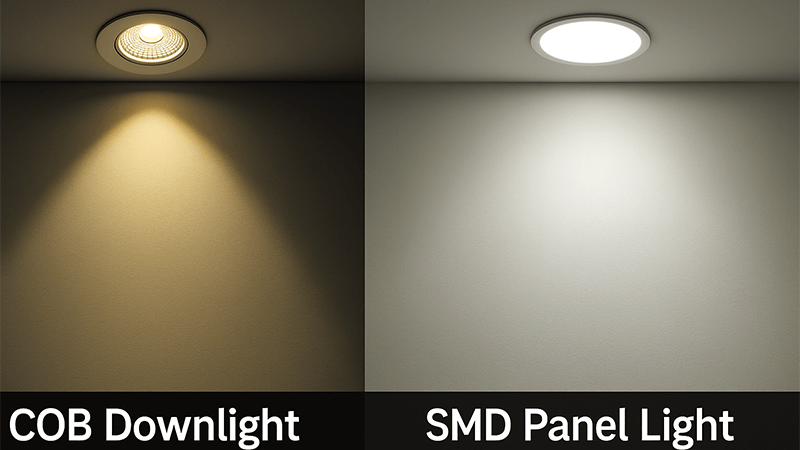

Light Quality and Appearance

COB LEDs create a single, uniform beam of light. Because all the tiny chips are packed into one module, they act like a single, powerful light source. This eliminates the multiple-shadow effect you can sometimes get with an array of SMD LEDs. This results in a clean, high-quality light that looks professional, which is perfect for retail showrooms or hotel lobbies where ambiance is key. SMDs, on the other hand, produce light from many individual points. While this is great for creating a wide, even spread of light in panel lights or bulbs, it can lack the "punch" needed for high-ceiling applications.

Thermal Performance and Lifespan

One of the biggest advantages of COB1 technology is its superior thermal management. The chips are mounted directly onto a substrate, often made of aluminum or ceramic, which acts as a large heat sink. This direct path allows heat to dissipate much more efficiently. In my experience, better heat management directly translates to a longer lifespan and more stable performance. SMD2s, being individual components, require each chip to have its own circuit and heat path. This can create more potential points of failure and thermal stress if not engineered perfectly.

Application Suitability

Choosing the right technology comes down to its intended use. Think of COB as a spotlight and SMD as a floodlight. For projects requiring high-intensity, directed light—like track lighting in an art gallery, architectural spotlights, or downlights for high ceilings—COB is the clear winner. For general area lighting where a wide, diffuse light is needed, like office ceiling panels or decorative strip lighting, SMD is more suitable and cost-effective.

Here's a simple breakdown to help you decide:

| Feature | COB (Chip-on-Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Light Output | Intense, focused, single light source | Distributed, wide-angle, multiple light sources |

| Best For | Spotlights, downlights, high-bay lights | Panel lights, strip lights, bulbs |

| Heat Dissipation3 | Excellent, direct path to heat sink | Good, but more complex thermal path |

| Appearance | Uniform, seamless beam | Can appear as multiple dots of light |

| Color Mixing | Less common in multi-color applications | Excellent for RGB and tunable white4 |

Ultimately, understanding the application is the first step. For a purchasing manager, asking "Where will this light be used?" is more important than asking "Which technology is better?".

What is the difference between a COB light and a surface light?

Your clients are asking for "surface lights," but the term seems vague. You're trying to figure out if they mean a specific technology or just any fixture mounted on a surface.

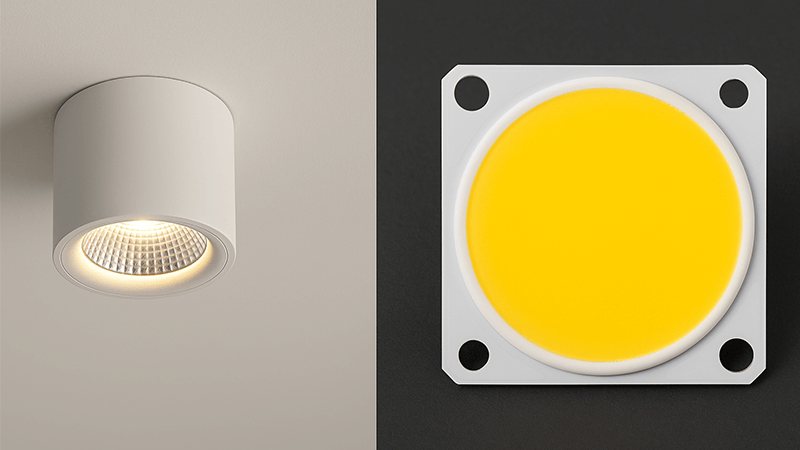

A COB light refers to the LED technology inside—a single module with many chips. A "surface light" describes the fixture's installation method—mounted directly onto a ceiling or wall, rather than recessed into it. A surface light can use either COB or SMD technology inside.

This is a common point of confusion I see with clients. It's like comparing the engine of a car to the type of car. One is a component, and the other is the final product. A "surface light," or more accurately, a surface-mounted fixture, is a category of luminaire defined by its installation. You've probably sourced thousands of them for projects where cutting into the ceiling wasn't an option, like in buildings with concrete ceilings or historical sites. These fixtures are practical, easy to install, and come in countless designs.

The Technology Inside the Fixture

The real question for a purchasing expert like Shaz is what kind of "engine" is best for that surface-mounted fixture. You can find surface-mounted cylinders, squares, and panels that use either COB or SMD LEDs. The choice impacts the light's performance dramatically. A surface-mounted downlight with a COB LED will produce a strong, focused beam, ideal for task lighting over a desk or highlighting an architectural feature. In contrast, a large, flat surface-mounted panel with SMD LEDs will provide soft, diffuse illumination perfect for general lighting in an office or corridor.

Why the Distinction Matters for Procurement

When you receive a request for a "surface light," the next step is to clarify the lighting goal. I always advise my partners to ask their clients:

- What is the purpose of the light? Is it for general ambiance, task lighting, or accenting a specific object?

- What is the ceiling height? High ceilings demand the powerful punch of a COB to deliver enough light to the floor.

- What kind of light quality is desired? Do they want a single, clean beam (COB) or a wide, distributed glow (SMD)?

Here’s how the technology choice for a surface light affects the outcome:

| Fixture Type | Recommended LED Technology | Rationale and Common Use Case |

|---|---|---|

| Surface-Mounted Downlight5 (Cylinder/Spot) | COB | Provides a powerful, directed beam. Perfect for task lighting in kitchens, retail displays, and high-ceiling residential spaces. |

| Surface-Mounted Panel Light (Square/Round) | SMD | Offers wide, even illumination with minimal glare. Ideal for general ambient lighting in offices, schools, and hospitals. |

| Surface-Mounted Track Light | COB | Each track head needs to be a spotlight to direct light precisely. COB provides the necessary focus and intensity for galleries and retail. |

| Surface-Mounted Linear Light | SMD | Creates a continuous, uniform line of light. Used for architectural and general lighting in modern commercial and residential interiors. |

By breaking it down this way, you move the conversation from vague terms to specific performance requirements. This allows you to source a product that not only fits the installation type but also delivers the precise lighting effect your client envisions. It’s this level of detail that separates a good purchasing manager from a great one.

How do you bend COB LED lights?

You're seeing flexible COB strips being used in amazing new designs. But you worry that bending them might cause damage, leading to costly failures and unhappy clients down the line.

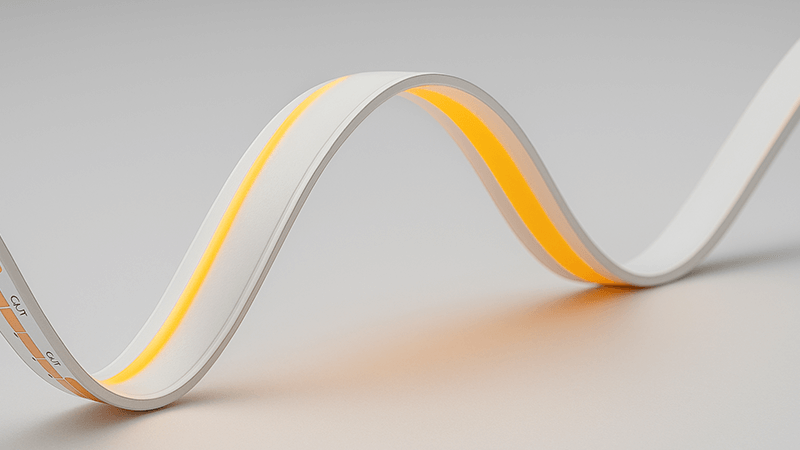

You can bend COB LED strips, but only along their designated axis. These strips are designed to be flexible lengthwise, not sideways. Always respect the manufacturer's specified minimum bend radius to avoid damaging the circuit or the chips, ensuring longevity and reliable performance.

I remember when flexible LED strips first came out; they were revolutionary. But early SMD versions had a "dotted" look that some clients didn't like. The new flexible COB strips solve this by providing a perfectly seamless line of light. They are fantastic for architectural accents, under-cabinet lighting, and creative installations. However, their flexibility comes with rules. I've seen projects go wrong because installers treated them like rope, and that's a mistake you can't afford.

Understanding the Structure of Flexible COB

A flexible COB strip is an engineering marvel. Microscopic LED chips are mounted directly onto a flexible printed circuit board (FPCB). This entire assembly is then coated in a translucent silicone or phosphor layer, which protects the chips and diffuses the light. The key to its flexibility is the FPCB, which is designed to bend in one direction—like a measuring tape. It can be rolled and unrolled, but you can't fold it sideways. Attempting to bend it against its designed axis will stress the solder joints and can crack the delicate chips or the circuit itself, causing sections of the strip to fail.

Best Practices for Bending and Installation

As a procurement manager, ensuring your clients receive proper handling instructions is part of delivering a quality product. Here are the critical rules I emphasize for our flexible COB products:

- Respect the Minimum Bend Radius: Every manufacturer specifies a minimum bend radius (e.g., 25mm or 50mm). This is the tightest curve you can make without risking damage. Bending it sharper than this will cause failures. I always make sure this spec is front and center on our technical data sheets.

- Never Fold or Crease: Do not fold the strip back on itself to make a sharp 90-degree corner. For sharp corners, the correct method is to cut the strip at the designated cut mark and use a solderless connector or solder wires to join two separate pieces at an angle.

- Bend Before Mounting: It's much easier and safer to shape the strip into the desired curve before peeling off the adhesive backing and sticking it in place. Bending it after it's been mounted can put uneven stress on the strip and the adhesive.

Here's a quick guide to handling corners with flexible COB strips:

| Corner Type | Recommended Method | Why it Works |

|---|---|---|

| Smooth Curve | Bend the strip gently along its length. | The FPCB is designed for this. Follow the minimum bend radius. |

| Sharp 90-Degree Corner | Cut the strip and use a 90-degree connector. | This avoids creasing the strip, which would damage the internal circuit. |

| Complex Angles | Cut the strip and solder flexible wires between sections. | This provides maximum flexibility for custom shapes without damaging the LED strips. |

By educating yourself and your clients on these simple rules, you can confidently use flexible COB strips to create stunning, seamless lighting effects that are built to last. It’s all about understanding the product's limits and working with them, not against them.

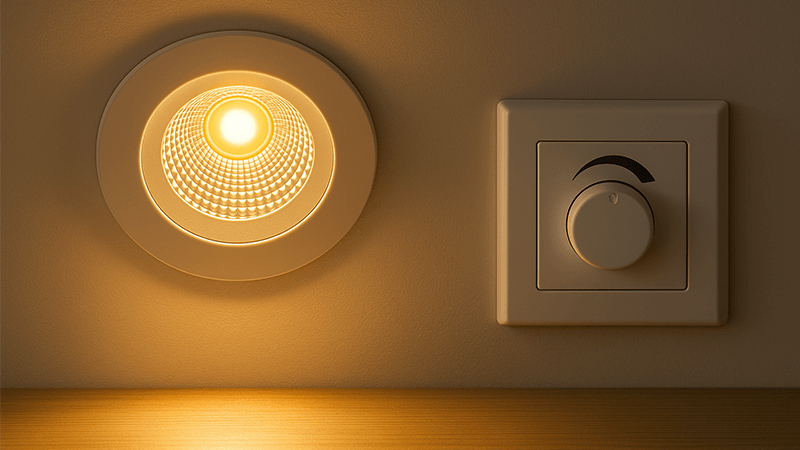

Can you dim COB LED lights?

Your project requires adjustable lighting levels for different moods and functions. You're considering COB downlights for their power but need to know if they can be dimmed effectively without issues.

Yes, most COB LED lights are dimmable, but you must use a compatible system. This means pairing the COB fixture with the correct type of LED driver6 and a compatible dimmer switch (e.g., TRIAC, 0-10V, or DALI7) to ensure smooth, flicker-free performance.

In my years of manufacturing, one of the most common technical support questions revolves around dimming. A client will install beautiful COB downlights but find they flicker, buzz, or don't dim smoothly. In 99% of cases, the problem isn't the COB light itself but an incompatibility between the driver, the fixture, and the dimmer switch. It’s like putting the wrong fuel in a high-performance engine—it just won’t work correctly. For a purchasing professional like Shaz, ensuring all three components are compatible from the start is the key to a successful dimmable lighting project.

The Holy Trinity of Dimming: Fixture, Driver, and Dimmer

Dimming8 LEDs is not as simple as dimming old incandescent bulbs. It's a technical system where every part must communicate perfectly.

- The COB Fixture: The COB LED module itself can handle changes in current, which is how dimming works. The fixture it's housed in must be designed to manage the heat effectively, even at low light levels.

- The LED Driver: This is the most critical piece. The driver is what converts the AC mains voltage to the low-voltage DC power the LED needs. A dimmable driver is required to interpret the signal from the dimmer switch and reduce the current to the COB LED smoothly. Non-dimmable drivers will not work.

- The Dimmer Switch: This is the user interface on the wall. Different drivers require different types of dimmer signals. Using a standard leading-edge dimmer with a driver that needs a 0-10V signal will result in failure.

Common Dimming Systems and How to Choose

Matching the driver to the dimmer is essential. Here are the most common systems I see used in commercial projects in regions like the UAE:

| Dimming Protocol | How it Works | Best Use Case | Key Consideration |

|---|---|---|---|

| TRIAC (Phase-Cut) | An older, 2-wire system that "chops" the AC sine wave. Common in residential retrofits. | Small-scale projects, retrofitting existing wiring. | Can be prone to flickering or buzzing if the driver and dimmer are not perfectly matched. Use "trailing-edge" for LEDs. |

| 0-10V | A 4-wire analog system. Two wires for power, two low-voltage wires send a signal from 0V (off) to 10V (100% brightness). | Reliable for commercial projects like offices and retail. Allows for easy integration into control systems. | Requires extra low-voltage wiring to be run from the switch to each driver, increasing installation complexity. |

| DALI | A 2-way digital system that gives each fixture a unique address. Allows for individual control, grouping, and status feedback. | Large, smart building projects like hotels, airports, and modern offices where complex scene-setting and control are needed. | Most advanced and costly system, but offers unparalleled flexibility. Requires specialized DALI drivers and controllers. |

For Shaz, when a client requests "dimmable COB lights," the follow-up questions should be: "What dimming system is being used or planned?" and "Is the electrical contractor running the necessary wiring for 0-10V or DALI if needed?" By specifying the complete system—fixture, driver, and control protocol—you prevent compatibility headaches and ensure the client gets the smooth, reliable dimming performance they expect.

Conclusion

COB technology's integrated design delivers superior lumen density. Understanding COB versus SMD, installation types, and dimming compatibility empowers you to source the perfect lighting solution for any project's needs

Explore the benefits of COB technology for high-intensity lighting applications. ↩

Learn about SMD technology and how it can be used for various lighting solutions. ↩

Explore how effective heat dissipation enhances LED performance and longevity. ↩

Learn about the versatility of RGB and tunable white LEDs in lighting design. ↩

Find out why surface-mounted downlights are ideal for various lighting scenarios. ↩

Discover the importance of LED drivers in ensuring optimal LED performance. ↩

Explore the benefits of DALI dimming for advanced lighting control systems. ↩

Learn about dimming options for COB LEDs and how to achieve smooth performance. ↩