Your showroom products look bland under flat, boring light. This costs you sales every day. COB LED downlights create focused, vibrant light, making your products look irresistible to customers.

COB (Chip on Board) LED downlights create high-impact lighting by packing many LED chips into one small module. This design produces a powerful, concentrated light beam with excellent color rendering and precise control, which is perfect for highlighting products and grabbing customer attention.

You now know that COB downlights create a powerful and focused beam. But to really understand their value, you need to look closer at the technology inside. I have spent my career working with these parts, and the details are what make a great light. It's not just about the chip. It is about how the whole system works together to perform reliably for years. So, let’s start with the basics of how they produce that clean, beautiful light.

How do COB LED lights work?

You hear that COB technology is better, but it sounds like just another technical word. Choosing the wrong product based on buzzwords can lead to early failures and disappointed clients.

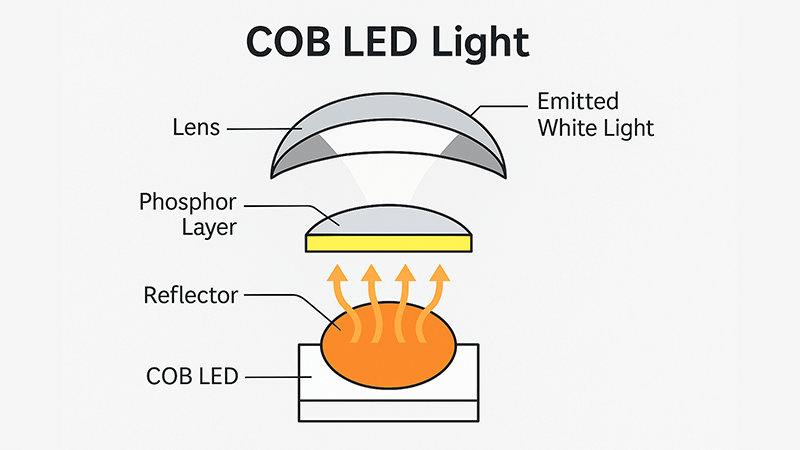

COB LED lights work by mounting multiple tiny LED chips directly onto a single base, usually made of aluminum or ceramic. These chips are wired together and then covered with a layer of phosphor. This creates one single, powerful, and uniform light-emitting surface.

Let's dive deeper into how this process creates such a high-quality light. The magic of COB technology is its simplicity and density. Instead of having many separate LEDs spread out, you have a tight cluster of them working as a single unit. This design has a few key parts that you need to know about.

The Core Components

A COB light is made of four main things. First are the LED chips1 themselves, which are the tiny diodes that produce blue light. Second is the substrate, which is the base layer that the chips are mounted on. Third are the bonding wires that connect all the chips into a single circuit. Finally, there is a layer of phosphor that coats everything. The phosphor is what converts the blue light from the chips into the white light we see. The quality of this phosphor greatly affects the Color Rendering Index (CRI)2 of the light. For a showroom, you want a high CRI to make product colors look true and vibrant.

A Critical Detail: The Lens

Many people overlook the lens, but it's a part where manufacturers can cut corners. The COB chip gets very hot in a small, concentrated area. The lens placed in front of it must handle this heat. I remember a new client, a purchasing manager like you, who had a big problem with lights from his previous supplier. After only six months, the downlight lenses in a luxury car showroom3 started to turn yellow and cloudy. This made the expensive cars look dull. We discovered the supplier used cheap polycarbonate (PC) lenses that couldn't handle the heat. The simple solution was to use a lens made of high-grade PC or PMMA that can resist high temperatures. As a rule, I always ensure the lens material4 can withstand at least 120°C. Anything less is a risk to the light's lifetime and performance. It’s a small detail that saves you from big problems later.

How do COB lights differ from other LEDs?

You see different LED types like SMD, MCOB, and COB. They all look like lights, so it is hard to choose the right one for your job. Making the wrong choice can result in uneven light or a look that cheapens your display.

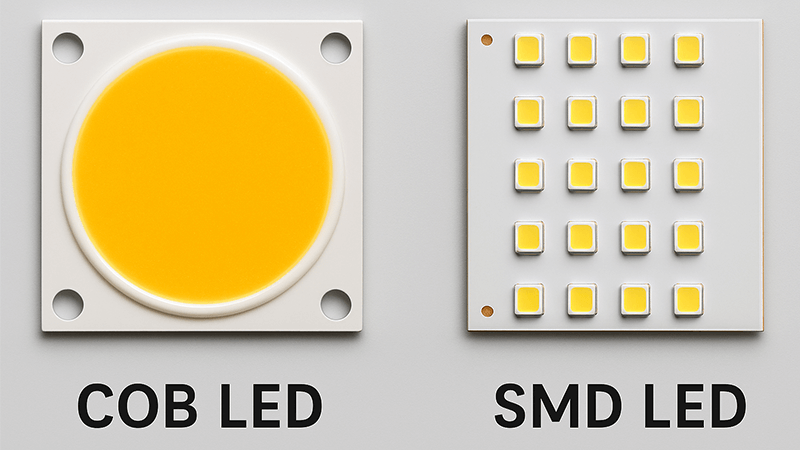

The main difference is in their structure. COB packs many tiny chips into one module to create a single, intense light source. SMD (Surface Mounted Device) uses larger, individual chips that are spaced apart on a circuit board, creating multiple points of light.

Understanding this structural difference is key to choosing the right light for your needs. It affects everything from the quality of the light beam to the best use for the fixture. Let's compare COB and its most common alternative, SMD, in more detail.

COB: The Spotlight Specialist

Think of a COB chip as a single, powerful cannon of light. Because all the light comes from one small point, it is very easy to control with a reflector or a lens. This allows you to create a clean, sharp-edged beam with minimal glare. This is exactly what you want for accent lighting in a showroom. You can precisely point the light to highlight a handbag, a piece of jewelry, or a specific feature on a car. The light is focused and intense right where you want it. This creates drama and draws the customer's eye. The uniform surface of the COB also means no multiple shadows, which can be distracting and look messy.

SMD: The Generalist

SMD chips are different. They are individual soldiers lined up on a circuit board. You can see the separate points of light. This is great for applications where you want to spread light over a large area, like in a panel light or an LED strip. To get a smooth light from SMDs, you need a thick diffuser to blend the light from all the different points. This diffuser can reduce the fixture's overall efficiency. For a spotlight, using SMD chips would require complex optics to try and focus all the different light points into one beam, and it's never as clean as a COB.

Which is Right for a Showroom?

For a showroom, COB is almost always the superior choice for accent and spot lighting. You need control and impact. You are not just lighting up a room; you are creating a visual experience. Here is a simple table to help you remember the difference.

| Feature | COB (Chip on Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Light Source | Single, uniform light source | Multiple, distinct light points |

| Appearance | Looks like a single lit panel | Looks like a collection of bright dots |

| Beam Quality | Focused, intense, clean beam | Wide, diffuse, needs a diffuser |

| Best For | Spotlights, downlights, accent lighting | Panel lights, strip lights, general area lighting |

What is the difference between spotlight and COB light?

People often mix up the terms "spotlight" and "COB light," which causes a lot of confusion when placing orders. This misunderstanding can lead to getting just a component when you wanted a complete product.

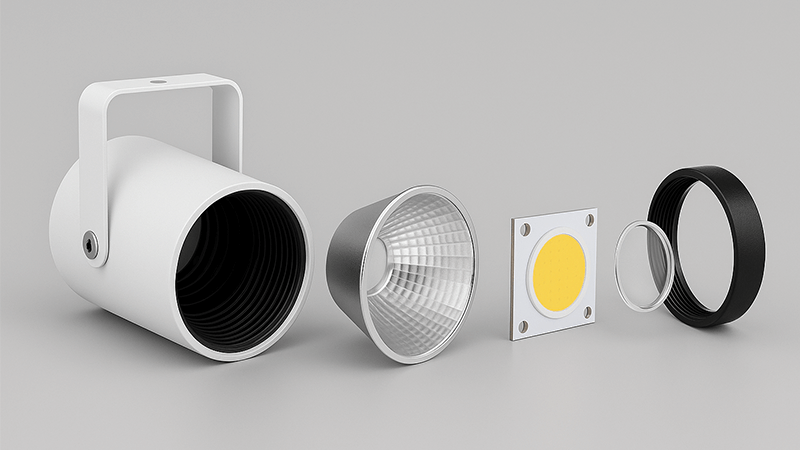

The key difference is simple: a "COB light" is just the light source itself—the chip module that creates light. A "spotlight" is the complete fixture that houses the COB chip, driver, heat sink, and reflector to direct the light.

It's helpful to think of it like building a car. You cannot drive an engine on its own. You need the full car. The same logic applies to lighting fixtures. Let's break this down further so you can be very precise when sourcing your products.

The Engine: The COB Chip

The COB chip is the engine of your spotlight. It's the part that does the most important job: creating light. The quality of the chip determines the brightness, energy efficiency, and color rendering of the fixture. When you look at a COB chip, you are looking at the core technology. There are many brands of COB chips, like Cree, Citizen, and Bridgelux. A good manufacturer will tell you which brand they use. However, a great engine is useless if the rest of the car is poorly built.

The Vehicle: The Spotlight Fixture

The spotlight is the complete vehicle. It takes the powerful light from the COB chip and turns it into a useful tool. The fixture includes several critical parts:

- Heat Sink: The COB chip produces a lot of heat in a small area. The heat sink5 is the metal body of the spotlight designed to pull this heat away and release it into the air. A poorly designed heat sink will cause the COB chip to overheat and fail quickly.

- Reflector or Lens: This part sits in front of the COB chip and shapes the light. A 24-degree reflector will create a narrow, intense spot. A 60-degree reflector will create a wider flood of light. The quality of the reflector's surface determines how clean and uniform the beam is.

- Driver: This is the power supply. It converts the main AC voltage from the wall into the low-voltage DC that the COB chip needs. A high-quality driver ensures a stable-free flicker light and protects the chip from power surges.

When you buy a spotlight, you are buying this complete system. The performance of the spotlight depends on how well all these parts work together. I always advise my partners to ask for a full specification sheet that lists the brand of the COB, the driver, and details about the fixture's thermal management. A good supplier will be transparent about every component, not just the COB chip.

What is the distance between COB lights?

You have bought the perfect COB downlights, but now you have to install them. If you place them incorrectly, you can completely ruin the lighting effect and waste all your effort.

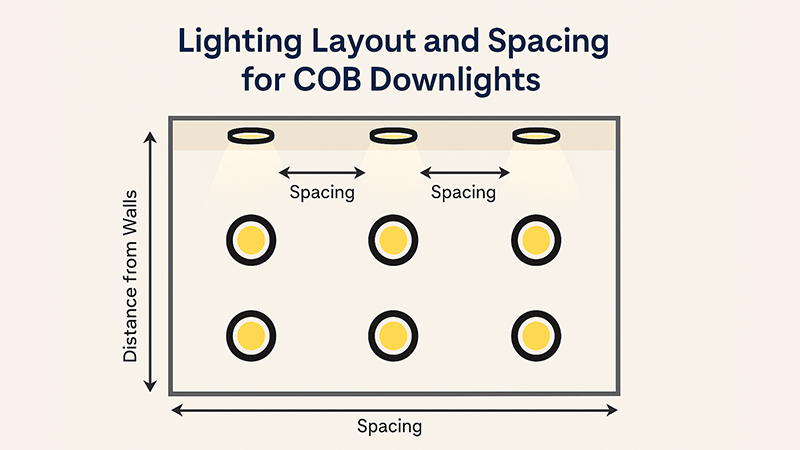

The ideal distance between COB lights depends mainly on two things: the ceiling height and the beam angle of the light. A good rule ofthumb is to aim for some overlap between the pools of light created by each fixture to avoid dark spots.

Calculating the right spacing is not as hard as it sounds. It is more important to understand the goal of your lighting. Are you trying to create general light for a whole room, or are you trying to highlight specific items? The answer will change your layout strategy. Let's look at a simple method to plan your spacing.

The Key Factors: Ceiling Height and Beam Angle

First, you need to know your ceiling height. Second, you must know the beam angle6 of your COB downlights. The beam angle (e.g., 24°, 36°, 60°) tells you how wide the cone of light is. A narrow angle like 24° is a "spot," while a wide angle like 60° is a "flood." Taller ceilings generally require narrower beam angles to make sure enough light reaches the floor or the target.

A Quick Calculation

You can estimate the diameter of the light pool on the floor. For a 3-meter ceiling and a 36-degree beam light, the circle of light on the floor will be about 1.9 meters wide. For a rough layout for general lighting, you could space the lights about 1.9 meters apart. However, this may create dim areas between the lights. To ensure smooth, even lighting, a better rule is to space the lights so their beams overlap. A good spacing for this is about 75% of the light pool's diameter. So, in our example, you would space the lights about 1.4 to 1.5 meters apart. This creates a beautifully even field of light with no dark patches.

Spacing for Different Applications

In a showroom, you often need different lighting strategies in the same space.

- Accent Lighting: Here, you forget the grid pattern. The spacing is determined by what you are lighting. You might have one light focused on a mannequin, and another one 3 meters away focused on a display table. The goal is to create contrast, not evenness.

- Wall Washing: To light a vertical wall display evenly, place the lights about 1 meter away from the wall for a 3-meter ceiling. The spacing between the lights should be equal to their distance from the wall, so about 1 meter apart. This creates a smooth "wash" of light down the wall.

Here is a quick reference table for general spacing:

| Ceiling Height | Beam Angle | Recommended Spacing (General Lighting) |

|---|---|---|

| 2.5m | 36° | ~1.2m |

| 2.5m | 60° | ~2.1m |

| 3.0m | 24° | ~0.9m |

| 3.0m | 36° | ~1.5m |

Always remember that these are starting points. The best layouts come from understanding the goals of the space and adjusting the plan to match.

Conclusion

COB downlights are more than just hardware. Understanding how they work, how to identify quality, and how to place them gives you the power to create truly impactful showroom lighting7.

Explore the different types of LED chips and their applications in lighting technology. ↩

Understand why CRI matters for showcasing products and ensuring true color representation. ↩

Find out the best lighting solutions for luxury car showrooms to enhance vehicle presentation. ↩

Discover the best lens materials to ensure durability and performance in your lighting fixtures. ↩

Find out how a heat sink affects the performance and longevity of LED lighting systems. ↩

Understand how beam angle influences lighting design and the visual impact in spaces. ↩

Discover best practices for showroom lighting to create an inviting and effective display. ↩