Having trouble with glare and uneven light from your downlights? Your projects deserve better, more uniform illumination, and the technology you choose is the key to achieving it.

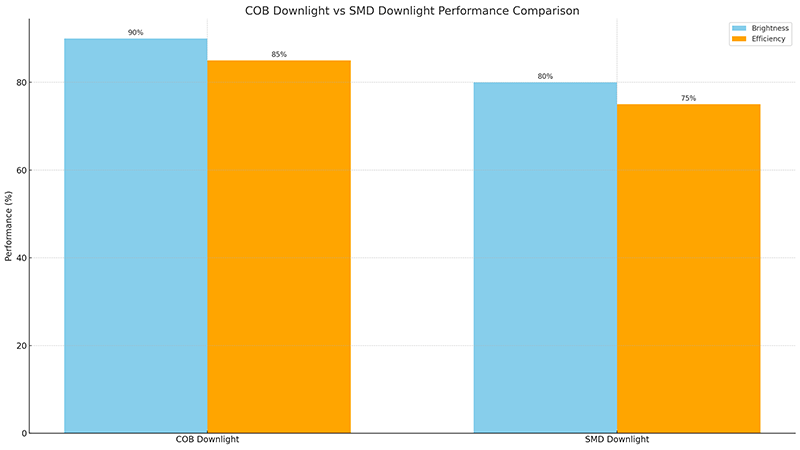

COB (Chip on Board) downlights provide a single, focused beam of light, which reduces glare and creates an ideal spotlight effect. In contrast, SMD (Surface Mounted Device) downlights use multiple smaller LEDs to produce wider, more dispersed illumination. The core performance difference lies in light quality and beam control.

I often get asked which type of downlight is "better." The truth is, it's like asking if a screwdriver is better than a hammer. Both are excellent tools, but they excel at different jobs. For a purchasing manager, making the right choice between them can be the difference between a satisfied client and a failed project. Understanding the details of their performance is crucial for making the right call every time. Let's look at the specifics to help you make informed decisions for your clients.

How long do COB lights typically last?

Are you worried about early failures and frequent replacements in your lighting projects1? Choosing a COB light is not just about its initial brightness; it is about ensuring long-term reliability for your clients.

A well-made COB LED light can last between 30,000 to 50,000 hours. This lifespan, however, depends heavily on effective heat management2. Poor thermal design, especially in high-power units, can drastically reduce this figure and lead to premature failure.

The lifespan of a COB LED3 is all about temperature. These chips pack a lot of power into a very small area. This creates a lot of heat. If that heat is not drawn away efficiently, the LED chip will degrade quickly, lose brightness, and fail. The main component responsible for this is the heat sink. A larger, well-designed aluminum heat sink is the first sign of a quality fixture.

But it goes deeper than just the visible heat sink. The material the LED chip is mounted on, called the substrate, is even more critical. This is where my experience as a manufacturer comes in. I remember a client from a hot climate, much like the UAE, who was facing constant failures with high-power COB downlights. They were failing in less than a year. The issue was that the manufacturer used a standard aluminum substrate for a powerful 50W COB. The heat simply could not escape fast enough, causing it to build up and destroy the chip.

The Critical Role of Substrates in Heat Dissipation

We solved his problem by specifying a different substrate. For high-power COB lights, I always recommend using an Aluminum Nitride (AlN) ceramic substrate4. Regular aluminum substrates are fine for lower power, but they can't handle the heat from more intense chips.

| Substrate Material | Thermal Conductivity (W/m·K) | Best Use Case |

|---|---|---|

| Standard Aluminum PCB | ~1-3 W/m·K | Low-power SMD or very low-power COB (<5W) |

| Copper Substrate | ~385 W/m·K | Good for mid-power COB, but expensive |

| Alumina (Al2O3) Ceramic | ~20-30 W/m·K | Better than aluminum, good for mid-power |

| Aluminum Nitride (AlN) | >150 W/m·K | High-power COB (>20W), essential for hot climates |

By switching his order to COBs built on an AlN substrate, the lights could finally run at a safe temperature. Years later, those fixtures are still performing perfectly. This is a technical detail many overlook, but it is the key to true, long-lasting performance. The quality of the LED driver also plays a huge part. A cheap driver will fail long before a 50,000-hour LED chip does. Always ensure the driver's lifespan matches the LED's.

What is the best color for COB lights?

Are your clients complaining that colors look unnatural or spaces feel uncomfortable under your lights? The right light color can completely change the atmosphere and function of a room.

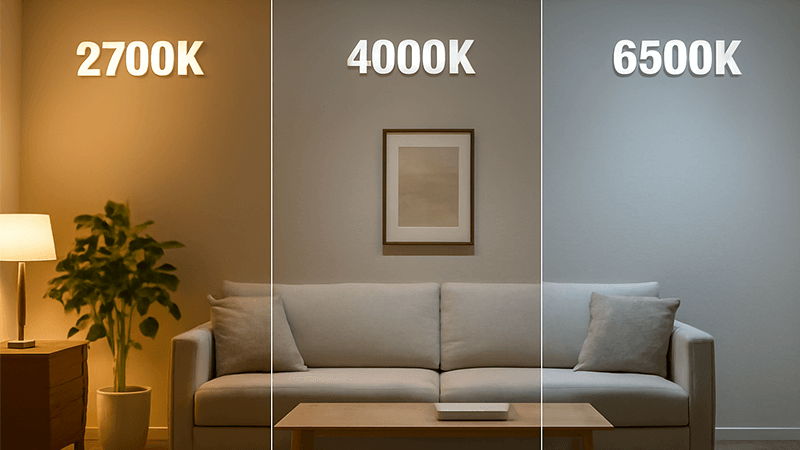

The "best" color for COB lights depends entirely on the application. For commercial and office spaces, a neutral white of 4000K is popular. For creating a cozy atmosphere in homes or restaurants, a warm white of 2700K-3000K is ideal.

When we talk about the "color" of white light, we are talking about two main things: Correlated Color Temperature (CCT)5 and Color Rendering Index (CRI)6. As a purchasing manager, understanding both is essential for specifying the right product. CCT is measured in Kelvin (K) and describes how "warm" or "cool" the light appears. Warm light has a yellowish tone, like a traditional incandescent bulb, while cool light is crisp and blueish, like daylight.

COB technology7 is fantastic because it allows for very consistent and high-quality light. Unlike some SMD solutions that can have slight color variations between chips, a COB is a single light source, ensuring perfect uniformity. This is huge for projects where you have many downlights in one space. You cannot have one looking slightly more yellow than the others.

Choosing the Right CCT and CRI for Your Project

The next critical factor is CRI. This scale, from 0 to 100, measures how accurately a light source reveals the true colors of objects. For any application where color is important, like retail stores, art galleries, or high-end homes, a high CRI8 is non-negotiable. One of the best performance aspects of COB technology7 is its ability to deliver very high CRI, often 90 or even 97+. This makes fabrics, food, and skin tones look vibrant and natural.

When I work with a purchasing manager like Shaz, our conversation quickly moves beyond just CCT. For a luxury retail project in Dubai, a CRI of 95+ is a must-have. For a standard office project, a CRI of 80+ is often sufficient. Here is a simple guide:

| Application | Recommended CCT | Recommended CRI |

|---|---|---|

| Residential (Living Areas) | 2700K - 3000K | 90+ |

| Office / Commercial | 4000K | 80+ |

| Retail (Fashion, Jewelry) | 3000K - 4000K | 95+ |

| Hospitality (Restaurants) | 2700K | 90+ |

| Art Galleries / Museums | 3000K - 4000K | 97+ |

The ability to specify both the exact CCT and a high CRI is a major performance benefit of using quality COB downlights. It gives you precise control over the look and feel of a space.

How many lumens is a COB light?

Are you confused by all the lumen ratings9 and not sure how much light you're really getting? Choosing the wrong light output can leave a space too dim or uncomfortably bright.

COB lights do not have one standard lumen value. The output varies widely based on power (wattage)10 and efficiency (lumens per watt). For example, a small 5W COB downlight11 might produce 400 lumens, while a large 50W COB can easily produce 5000 lumens or more.

One of the most common mistakes I see people make is focusing only on the wattage of a light. It's an old habit from the days of incandescent bulbs. In the world of LEDs, the most important number is not watts, but luminous efficacy12. Efficacy is the measure of how efficiently a light fixture turns electricity (watts) into light (lumens). It is expressed as lumens per watt (lm/W).

A higher efficacy means you get more light for less energy. This is a critical performance metric for any large project, as it directly impacts the client's electricity bill. COB technology7 has made incredible advancements here. The best COB chips on the market today can achieve very high efficacy values, far surpassing what was possible just a few years ago.

Understanding Luminous Efficacy for Better Purchasing

Let’s imagine a purchasing manager is comparing two 10W COB downlights for an office project.

- Supplier A offers a downlight that produces 800 lumens. Its efficacy is 80 lm/W.

- Supplier B offers a downlight that produces 1200 lumens. Its efficacy is 120 lm/W.

Both are 10W fixtures, but Supplier B's product is 50% more efficient. It provides dramatically more light for the exact same energy cost. For a project with hundreds of downlights, the energy savings are massive. This is the kind of value I focus on when developing products. We always aim for the highest efficacy possible to deliver true performance.

| Chip Quality | Typical Wattage | Efficacy (lm/W) | Resulting Lumens |

|---|---|---|---|

| Economy Tier | 10W | 80 lm/W | 800 lm |

| Mid Tier | 10W | 100 lm/W | 1000 lm |

| Premium Tier | 10W | 130 lm/W | 1300 lm |

Another key performance factor is the optics. The raw lumen output from the COB chip is not what matters most. What matters is the light delivered by the fixture after it passes through the reflector and lens. COB's small, single-point source allows for highly efficient optical design. With a well-engineered reflector, we can direct nearly all the light exactly where it is needed, minimizing waste and maximizing useful lumens.

What is the full form of SMD light?

Are you feeling lost in a sea of technical acronyms from suppliers? Understanding the basics, like what SMD actually means, is the first step to making smarter sourcing decisions.

SMD is an acronym that stands for "Surface Mounted Device." In lighting, this refers to an LED chip that is designed to be mounted directly onto the surface of a printed circuit board (PCB).

The term "Surface Mounted Device" is not exclusive to LEDs. It's a broad term for any electronic component that is soldered directly onto a board. The alternative is "through-hole" technology, where components have long leads that go through holes in the board. SMD technology13 allowed for much smaller and more automated electronics manufacturing, and it's what makes modern, compact LED lighting possible.

When we talk about an SMD downlight, we are talking about a product that uses a PCB populated with many of these individual SMD LED chips. Common SMD chips you might see in specifications include types like 2835, 5050, or 3030. These numbers refer to the dimensions of the chip (e.g., 2835 is 2.8mm x 3.5mm).

SMD vs. COB14: A Manufacturing and Performance Perspective

From a manufacturing perspective, the process for SMD and COB is quite different, and this directly impacts their performance. For an SMD light, we take a PCB and use a machine to place dozens or even hundreds of individual SMD chips onto it. For a COB light, we take a single substrate and bond the raw, unhoused LED diodes directly to it, then cover them all with a single layer of phosphor.

This fundamental difference leads to the primary performance distinctions.

| Feature | SMD (Surface Mounted Device) | COB (Chip on Board) |

|---|---|---|

| Light Source | Multiple individual points of light spaced apart | A single, uniform, and dense point of light |

| Visual Appearance | Can look like a pattern of "dots" without a good diffuser | Appears as one single, smooth light source |

| Beam Control | Harder to control; best for wide, diffused light | Easy to control with reflectors for focused beams |

| Heat Management | Heat is spread out across many points on a large PCB | Heat is highly concentrated in one small area |

| Typical Application | Panel lights, LED strips, bulbs for general lighting | Downlights, track lights, spotlights |

The SMD approach is perfect for products that need a large, diffuse lighting area, like a flat panel light. The many points of light blend together behind a diffuser to create an even glow. However, for a downlight, where you want to punch light down with control and avoid glare, the COB approach is superior. It perfectly mimics the single-point source of a halogen lamp that lighting designers prefer, allowing for clean, crisp beams without the "multi-shadow" effect that can come from an array of SMD chips.

Conclusion

Ultimately, choosing between COB and SMD is about matching the technology to the application. COB excels at providing focused, high-quality, and controlled light, while SMD is great for wide, general diffusion.

Discover best practices to ensure successful outcomes in lighting projects. ↩

Explore the critical role of heat management in ensuring LED reliability and performance. ↩

Find out how long COB LEDs last and factors affecting their longevity. ↩

Learn why AlN substrates are essential for high-power COB lights in hot climates. ↩

Understand CCT and how it influences the atmosphere of a space. ↩

Discover the significance of CRI in accurately representing colors under artificial light. ↩

Learn about the latest advancements in COB technology for improved lighting solutions. ↩

Discover the standards for high CRI and its importance in various lighting scenarios. ↩

Explore how lumen ratings help in selecting the right brightness for spaces. ↩

Explore the relationship between wattage and light output in LED technology. ↩

Learn about various downlight types and their applications in lighting design. ↩

Learn about luminous efficacy and its impact on energy efficiency in lighting. ↩

Find out how SMD technology revolutionizes LED manufacturing and performance. ↩

Explore the key differences between SMD and COB technologies for informed decisions. ↩