Poor airport lighting creates glare and dark spots. This frustrates travelers and ruins their experience. COB LED downlights solve this by providing a clear, uniform light for modern terminals.

COB (Chip on Board) LED downlights significantly improve airport illumination by delivering a powerful, single point of light. This creates a focused, high-quality beam with minimal glare, similar to traditional halogen lamps but with much higher efficiency and a longer lifespan, enhancing visibility and passenger comfort.

The right lighting transforms an airport from a stressful transit hub into a welcoming space. I've seen it happen many times. But achieving that perfect balance isn't simple. There are many factors at play, from safety regulations to passenger comfort. Understanding these elements is the first step toward creating a world-class airport environment. So, let's look closer at what really goes into lighting such a massive and important space.

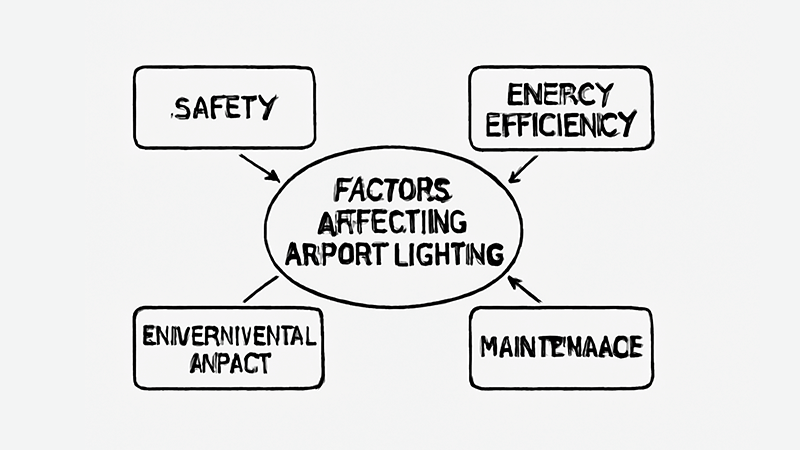

What are the factors affecting airport lighting?

Planning airport lighting is complex. A poor decision impacts safety, energy costs, and passenger mood. Focusing on a few key factors makes the process manageable and ensures great results.

Key factors affecting airport lighting include ensuring passenger safety and security1, enhancing visual comfort by minimizing glare, meeting strict aviation regulations2, achieving high energy efficiency3 to reduce operational costs, and simplifying maintenance in hard-to-reach areas4. Each factor is critical for a successful installation.

Lighting an airport is not like lighting an office or a home. The scale is massive, and the stakes are much higher. Every decision must be balanced against several critical factors. I always tell my clients, like Shaz, that we need to think about the entire lifecycle of the lighting system, not just the initial brightness.

Safety and Security: The Top Priority

First and foremost, airport lighting must ensure safety. This means providing clear visibility in all areas, from check-in counters to baggage claim. Good lighting helps security personnel and CCTV cameras monitor the space effectively, deterring potential threats. It also ensures that emergency exits and evacuation routes are always clearly lit. There is no room for error here. A single dark corner can become a security risk. That's why we always aim for uniform light distribution, eliminating shadows where someone could hide or trip.

Passenger Experience and Visual Comfort

Next, we must consider the comfort of millions of travelers. Airports can be stressful environments. Harsh lighting with excessive glare only makes things worse. We use lighting to create a welcoming and calm atmosphere. This involves choosing fixtures with a good Unified Glare Rating (UGR)5 and a high Color Rendering Index (CRI)6. A high CRI makes colors appear natural and vibrant, which not only looks better but also helps people read signs and recognize faces more easily. This focus on visual comfort7 directly improves the passenger journey.

Operational Demands: Energy and Maintenance

Finally, we can't ignore the operational side. Airports operate 24/7, so energy consumption is a huge expense. Switching to energy-efficient solutions8 like LEDs can lead to massive cost savings. Maintenance is another major challenge. Ceilings in terminals can be very high, making it difficult and expensive to replace a single burnt-out lamp. This is why long-lifespan fixtures9 are essential. A reliable product with a 50,000-hour life means fewer replacements, less disruption, and lower long-term costs.

| Factor | Description | Impact on Airport Operations |

|---|---|---|

| Safety & Security | Clear, uniform illumination for all areas. | Enhances CCTV effectiveness, ensures clear paths, deters crime. |

| Visual Comfort | Low glare (UGR) and high color rendering (CRI). | Reduces passenger stress, improves navigation, creates a welcoming atmosphere. |

| Energy Efficiency | Low power consumption (Watts) for high light output (lumens). | Drastically reduces electricity bills for 24/7 operation. |

| Longevity & Maintenance | Long lifespan and durable construction. | Minimizes costly and disruptive maintenance in high-ceiling areas. |

| Regulations | Compliance with local and international aviation standards. | Ensures legal operation and avoids penalties. |

What is one major benefit of using LED lighting in buildings?

Traditional lighting drains building budgets with high energy bills and constant maintenance. These recurring costs are a huge operational burden. LED lighting provides a massive benefit that saves money and time.

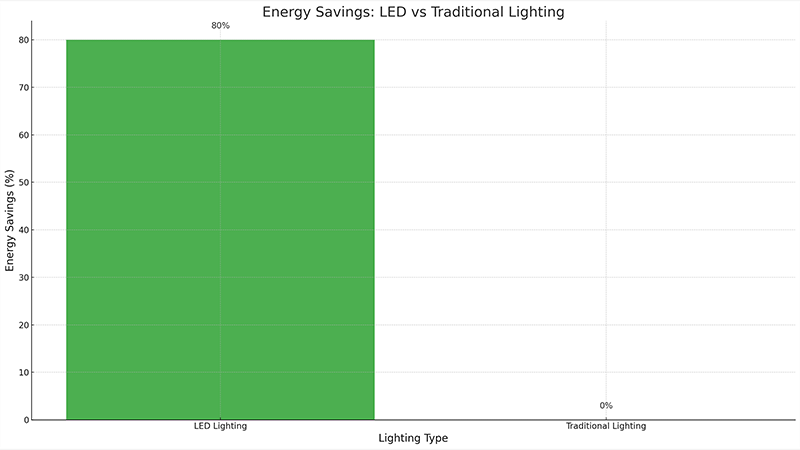

The single biggest benefit of using LED lighting in buildings is its exceptional energy efficiency. LEDs consume up to 80% less energy than traditional lighting technologies like incandescent or fluorescent bulbs. This translates directly into significant, long-term operational cost savings, especially for large facilities.

When I discuss lighting projects with purchasing managers like Shaz, the conversation always turns to cost. While the initial investment is important, the major benefit of LED lighting is its impact on long-term operational costs. This is primarily due to its incredible energy efficiency. It’s not just a minor improvement; it’s a game-changer for any large building, especially an airport.

Understanding Luminous Efficacy

The key metric here is luminous efficacy10, measured in lumens per watt (lm/W). This tells us how much light a source produces for every watt of electricity it consumes. Traditional incandescent bulbs are terribly inefficient, converting most of their energy into heat, not light, with an efficacy of around 15 lm/W. Fluorescent tubes are better, at around 60-90 lm/W. But modern LEDs can easily exceed 150 lm/W. This means you get the same amount of light, or even more, for a fraction of the power consumption. It’s a simple but powerful advantage.

A Real-World Example

I remember working on a terminal renovation project a few years ago. They were using thousands of 75-watt halogen downlights. The lights were on for at least 18 hours a day. We replaced them with 15-watt LED downlights that produced the same amount of light. The energy savings were immediate and massive. The airport's facility manager later told me their electricity bill for lighting dropped by nearly 80%. Over a year, this translated into hundreds of thousands of dollars in savings, allowing them to invest in other passenger experience upgrades11.

The Ripple Effect of Efficiency

The savings don't stop at the electricity bill. Because LEDs produce far less heat, the building's air conditioning system doesn't have to work as hard to cool the space. This creates a secondary, significant energy saving. Furthermore, because LEDs last so much longer, the costs associated with purchasing replacement bulbs and hiring labor for maintenance are almost eliminated. It is a compounding benefit that makes LED the clear choice.

| Lighting Technology | Typical Efficacy (lm/W) | Average Lifespan (hours) | Heat Output |

|---|---|---|---|

| Incandescent | 10-17 | 1,000 - 2,000 | Very High |

| Halogen | 16-24 | 2,000 - 4,000 | High |

| Fluorescent (CFL) | 50-70 | 8,000 - 15,000 | Low |

| LED | 100-180+ | 25,000 - 50,000+ | Very Low |

How to control airport lighting?

Leaving all airport lights on full power is wasteful. It inflates energy bills and ignores natural daylight. Smart control systems solve this by automating and optimizing light levels for you.

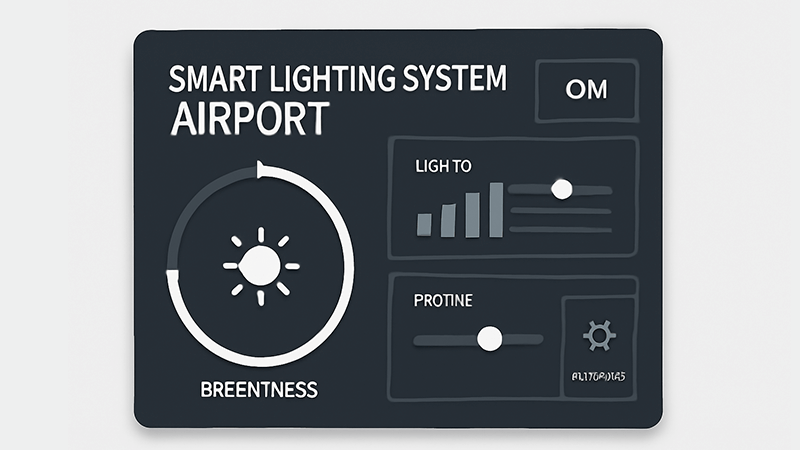

Airport lighting is controlled through sophisticated Lighting Management Systems (LMS)12. These systems use a combination of scheduling, occupancy sensors13, and daylight harvesting sensors14. They allow facility managers to automate lighting levels, dimming lights in unused areas or when natural light is sufficient, maximizing energy savings.

In my experience, the biggest leap forward in lighting isn't just the LED itself; it's how we control it. In a space as dynamic as an airport, a static 'on/off' system is obsolete. Modern airport lighting relies on intelligent control systems that adapt in real-time. This is how we move from just saving energy to truly optimizing it. It's a conversation I always have with knowledgeable clients like Shaz, who understand that the control system is as important as the luminaire.

Scheduled and Zoned Control

The most basic form of smart control is scheduling. An airport has different areas with different operational hours. Retail shops might close at night, but the main concourse remains open. A Lighting Management System (LMS) allows facility managers to create schedules for different zones. For example, lights in the shopping area can be dimmed to 20% after 11 PM, while lights in security areas remain at 100%. This simple strategy prevents wasting energy on lighting empty spaces.

Sensor-Based Automation

This is where the system gets truly intelligent. We integrate various sensors into the network.

- Occupancy Sensors: These are perfect for less-trafficked areas like restrooms, storage rooms, or administrative offices. The lights turn on when someone enters and automatically turn off after the space is vacant for a set period.

- Daylight Harvesting Sensors: Airports often have massive glass facades that let in a lot of natural light. These sensors measure the amount of ambient light and automatically dim the electric lights nearby. On a bright, sunny day, lights near the windows might dim to 30% or even turn off completely, saving a huge amount of energy without anyone noticing a difference.

Centralized Control Protocols

All these components—the lights, schedules, and sensors—need to talk to each other. This is done using control protocols like DALI (Digital Addressable Lighting Interface)15 or 0-10V dimming. DALI is particularly powerful because it allows for individual control of every single light fixture. From a central computer, a facility manager can get status reports, see energy consumption data, and even diagnose a faulty fixture without ever leaving their office. This level of granular control and monitoring is essential for managing a facility as large as an airport.

| Control Strategy | How It Works | Best Application in Airports |

|---|---|---|

| Scheduling | Lights are programmed to dim or turn off at specific times. | Retail areas after closing, gate areas between flights. |

| Occupancy Sensing | Motion sensors activate lights only when a space is occupied. | Restrooms, administrative offices, back-of-house areas. |

| Daylight Harvesting | Sensors measure ambient light and dim fixtures accordingly. | Gate areas, check-in halls, any space with large windows. |

| Centralized (DALI) | Each fixture is addressable and controlled from a central hub. | Entire airport-wide system for total control and diagnostics. |

What are the advantages of COB LED?

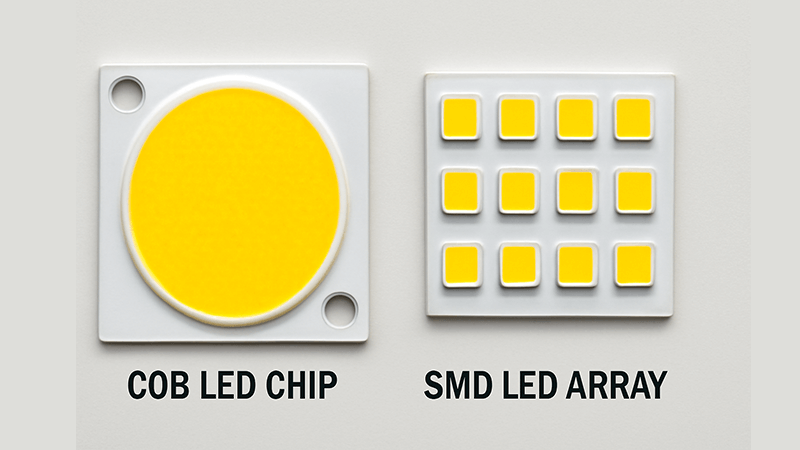

Choosing between different LED types is confusing. The wrong choice creates multiple shadows and poor light quality. COB LED technology16 solves this by delivering superior, single-point illumination.

The main advantages of COB (Chip on Board) LEDs are their ability to produce a powerful, uniform beam of light from a single source, eliminating multiple shadows. They also offer excellent thermal performance, high luminous efficacy, and a compact size, making them ideal for high-performance downlights17.

Not all LEDs are created equal. As a manufacturer, I spend a lot of time explaining the differences between technologies. For applications like airport downlights where light quality is paramount, I almost always recommend COB, or 'Chip on Board', technology. It's a design philosophy that brings several key advantages to the table.

A Single, Flawless Light Source

Unlike older SMD (Surface Mount Device) LEDs which use an array of many small, separate light points, a COB LED packs many diodes onto a single substrate. This makes it function like one large, single light source. The practical benefit is huge: it creates a clean, crisp beam with a single, soft-edged shadow. This is very similar to the pleasing light quality of a traditional halogen lamp. SMD fixtures, in contrast, can create multiple, messy shadows, which is distracting and looks unprofessional in a high-end space like an airport terminal. COB provides that premium lighting effect.

Expertise in Thermal Management

Here is a critical point I always stress to my partners. COB LEDs have a very high heat flux density because all the chips are concentrated in a small area. This intense heat must be managed effectively. If it isn't, the junction temperature of the chip will rise, causing the light output to decrease rapidly—a process we call light decay. To prevent this, the heatsink is non-negotiable. It must be made from high-grade aluminum extrusion fins and paired with a high-performance thermal grease with a thermal conductivity of at least 3.0 W/m·K. If this standard isn't met, the junction temperature can easily exceed 90°C, and the fixture's lifespan will be drastically shortened. This is a detail where quality manufacturing really shows.

High Efficacy in a Small Package

By mounting the LED chips directly onto the substrate, COB technology simplifies the design and allows for a higher packing density. This results in a very high light output from a very small surface area. This combination of compactness and high luminous efficacy makes COB LEDs perfect for spotlights and downlights, where we need to direct a powerful punch of light from a relatively small fixture.

| Feature | COB (Chip on Board) LED | SMD (Surface Mount Device) LED |

|---|---|---|

| Light Source | Single, uniform light point | Array of multiple small points |

| Shadow Quality | Single, soft shadow | Multiple, harsh shadows |

| Thermal Management | High heat density requires excellent heatsink | Heat is more spread out |

| Application | Ideal for spotlights, downlights, high-bay lights | Good for linear lights, panel lights, bulbs |

| Visual Effect | Clean, focused, high-quality beam | Diffused, widespread light |

Conclusion

COB LED downlights, combined with smart controls, offer airports superior light quality, massive energy savings, and long-term reliability. They are the key to a modern, efficient, and welcoming terminal.

Explore this resource to understand how effective lighting enhances safety and security in airports. ↩

This link provides insights into the strict regulations that govern airport lighting standards. ↩

Discover how energy-efficient lighting solutions can significantly reduce operational costs. ↩

Find out strategies for effective maintenance in challenging airport environments. ↩

This resource explains UGR and its role in enhancing passenger comfort. ↩

Learn about CRI and its significance in creating a visually appealing airport environment. ↩

Learn about the importance of visual comfort in creating a welcoming atmosphere for travelers. ↩

Find out about the latest energy-efficient technologies that can benefit airport lighting. ↩

Explore the benefits of long-lasting lighting solutions for airports. ↩

Learn how luminous efficacy impacts energy efficiency and lighting quality. ↩

Learn about innovative upgrades that improve the overall passenger experience in airports. ↩

This link details how LMS can optimize airport lighting and energy use. ↩

Discover how occupancy sensors can enhance energy savings in airport lighting. ↩

Learn about the benefits of integrating daylight harvesting in airport lighting systems. ↩

Find out how DALI technology improves control and efficiency in airport lighting. ↩

Explore the benefits of COB LED technology for high-quality airport lighting. ↩

This resource outlines the features that make downlights suitable for airport environments. ↩