Poor office lighting creates eye strain and hurts productivity. This negatively impacts employee well-being and your company's results, making the search for a better lighting solution a frustrating process.

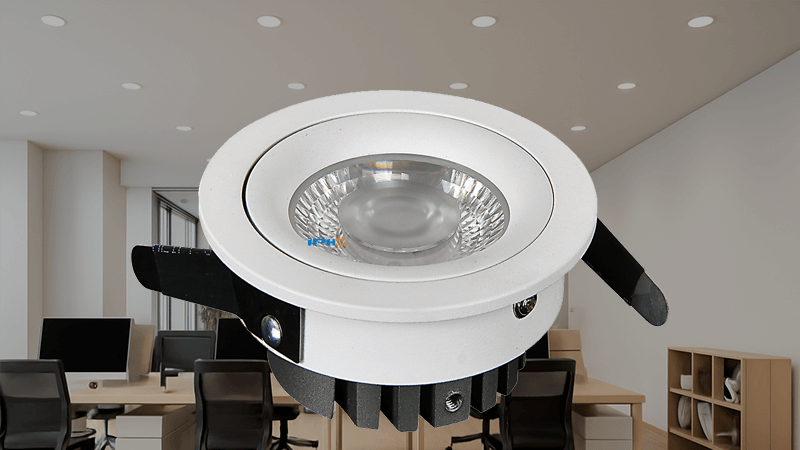

COB LED downlights significantly improve office lighting by delivering a powerful, uniform light from a single source. This technology creates a focused beam with excellent color accuracy and minimal glare, which enhances visual comfort, boosts concentration, and supports a more productive work environment.

But getting these benefits isn't as simple as just installing any COB downlight. The real magic happens in the details of the fixture's design and how it's applied within the space. As someone who has been manufacturing LED lights for years, I've seen firsthand how a small change in design can make a world of difference. Understanding why COB technology is a superior choice and how to select the right fixture is the key to unlocking its full potential. Let's break down exactly what makes these lights so effective for office environments.

What are the advantages of COB LED lights?

Choosing between the different types of LED technology can feel overwhelming. You worry that picking the wrong one will lead to poor performance and an unhappy client down the line.

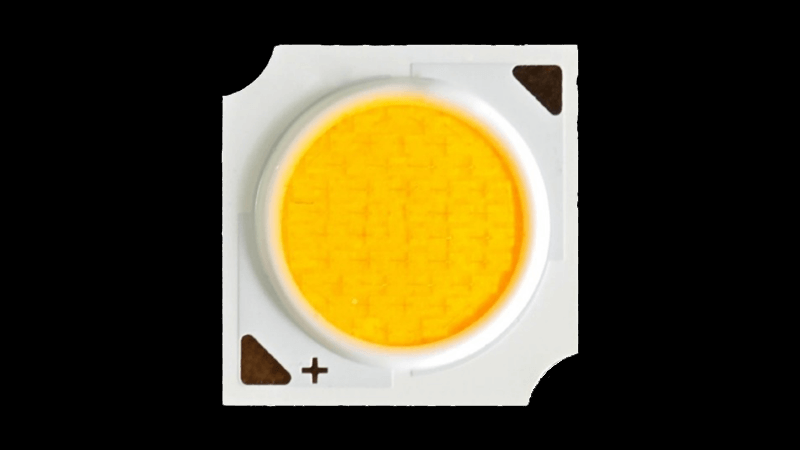

The main advantages of COB (Chip on Board) LEDs are their high light intensity from a compact area, simplified design, and superior heat management1. This results in brighter, more uniform light, greater reliability, and a longer lifespan2 compared to older LED technologies like SMD3.

Dive Deeper

When I first started in this industry, the evolution from traditional bulbs to LEDs was revolutionary. But even within the world of LEDs, there have been huge leaps forward. The move to COB technology was one of them, and for good reason. It solved several problems we faced with earlier LED designs.

Higher Lumen Density and Intensity

The term "lumen density4" sounds technical, but it's a simple concept. COB technology packs many tiny LED chips onto one small board, or substrate. Because they are so close together, they act as one large, single light source. This creates a powerful, concentrated beam of light. Think of it like the difference between a hundred tiny candles scattered in a room versus a single, powerful spotlight. The spotlight provides an intensity that the candles can't match. I remember a hotel project I worked on where the client wanted to replace old 50W halogen spotlights. They loved the "punch" of light from the halogens. Only COB LED downlights5 could deliver that same sharp, intense effect while offering massive energy savings.

Simplified Design and Better Heat Management

From a manufacturing and reliability perspective, simplicity is a huge advantage. Because a COB is a single module, the circuit design is much simpler. There are fewer solder points and components, which means there are fewer things that can fail. For a purchasing manager like Shaz, who values reliability above all, this is a critical point. Fewer failures mean fewer warranty claims and a better reputation.

More importantly, this simple design is key to a longer life. The LED chips are mounted directly onto a substrate, usually aluminum or ceramic, which is excellent at conducting heat. This creates a direct, efficient path for heat to escape from the chips to the heatsink. Heat is the number one enemy of an LED. The cooler it runs, the longer it lasts and the more stable its light output will be. At my factory, iPHD, we can see the difference clearly. A well-designed COB fixture runs much cooler than a poorly designed one, and our testing shows it will last for tens of thousands of hours longer.

| Feature | COB LED Advantage | Impact on Performance |

|---|---|---|

| Light Source | Single, concentrated point | High intensity, uniform beam |

| Circuitry | Simplified, one circuit | Increased reliability, fewer failure points |

| Thermal Path | Direct to substrate | Superior heat dissipation, longer lifespan |

| Luminous Efficacy | High lumens per watt | Better energy efficiency |

How to improve lighting in an office?

You've invested in new office lighting, but employees are still complaining about headaches and glare6. The new lights seem bright, but they are just not comfortable to work under.

To truly improve office lighting, you must focus on reducing glare to a Unified Glare Rating (UGR) below 19. Using COB downlights with deep anti-glare reflectors7 and ensuring high color accuracy8 (CRI >90) creates a comfortable, productive, and visually appealing environment.

Dive Deeper

Good office lighting is about more than just brightness; it's about the quality of that light. I've consulted on countless office projects, and the most common complaint I hear is about glare. People don't want to feel like they are staring into a car headlight while trying to work on a computer. This is where the specific design of the downlight becomes the most important factor.

The Critical Role of Glare Control (UGR)

The lighting industry uses a metric called the Unified Glare Rating (UGR)9 to measure the discomfort caused by glare. For task-oriented spaces like offices, the international standard recommends a UGR of 19 or less (UGR≤19). A lower number is better. When a fixture has a high UGR, it creates reflections on screens and causes our eyes to constantly readjust, leading to strain and fatigue. Achieving a low UGR isn't an accident; it's a deliberate result of good luminaire design. I always tell my clients, especially experienced buyers like Shaz, that they shouldn't just ask for a "COB downlight." They must specify "UGR less than 19." It’s a detail that separates a good office lighting plan from a bad one.

The Secret is in the Design: Deep Reflectors

So, how do we get that low UGR with a powerful COB light source? The answer is surprisingly simple: the depth of the reflector. My key insight for any office project is that the downlight's reflector cup must be at least 40 mm deep. When the COB chip is positioned deep inside the fixture, the reflector can direct the light straight down. This creates a sharp cut-off angle, meaning you can't see the bright light source itself unless you are standing directly underneath it and looking straight up. The light illuminates the desk and the floor, not your eyes.

I once helped a client in the UAE who had just moved into a beautiful new office but was having a huge problem with glare6. Their architects had chosen a very stylish but shallow downlight. We did a test in one room, replacing their fixtures with our deep-reflector COB model. The only major change was the reflector depth10. The difference was immediate. The room felt just as bright, but all the harshness was gone. They immediately placed an order to change the lights in the entire building.

| Parameter | Office Standard | Why It Matters | How COB Downlights Help |

|---|---|---|---|

| Glare (UGR) | ≤ 19 | Prevents eye strain11 & headaches | Deep-reflector designs control light output |

| Reflector Depth | ≥ 40 mm | Hides the light source from direct view | Creates a comfortable cut-off angle |

| Color Rendering (CRI) | > 90 | Ensures colors look natural, reduces eye fatigue | High-quality COB chips offer excellent CRI |

| Flicker | Flicker-Free | Avoids subliminal visual stress & headaches | Quality drivers paired with COB provide stable current |

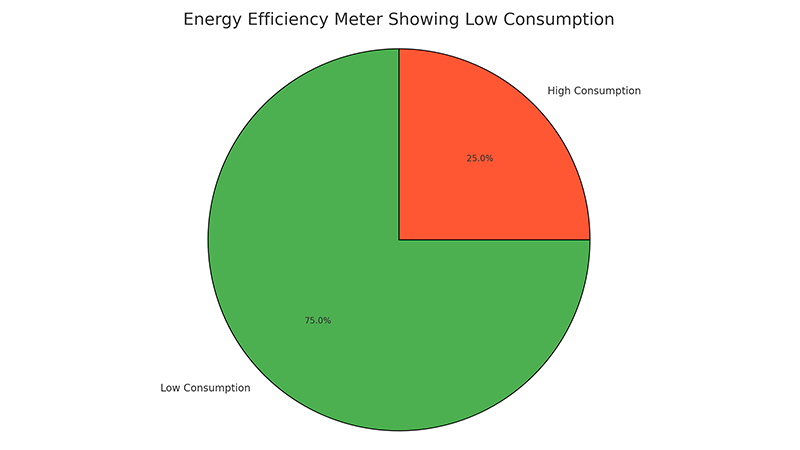

Does COB light consume more electricity?

You hear that COB lights are "high intensity," and your mind immediately jumps to a high electricity bill. This fear might stop you from choosing a superior technology for your project.

No, COB lights are actually very energy-efficient12 and do not inherently consume more electricity. Power consumption is determined by a light's wattage, and COB technology excels at producing more light (lumens) for every watt of energy it uses.

Dive Deeper

This is one of the most common misconceptions I have to clear up for clients. The words "powerful" and "intense" often make people think of high energy use, but with modern LEDs, the opposite is usually true. Efficiency is the name of the game.

Wattage vs. Brightness (Lumens)

The first thing to understand is the difference between wattage and lumens. Wattage (W) measures the amount of electrical power a device consumes. Lumens (lm) measure the amount of visible light a device produces. A 10W COB downlight and a 10W SMD3 downlight both consume exactly 10 watts of power. The real question is not how much power they use, but how much light they give you for that power. This is where efficiency comes in. Intensity comes from focusing those lumens into a specific area, not from using more power.

The Efficacy Equation: Lumens per Watt (lm/W)

The key metric to look for is luminous efficacy13, measured in lumens per watt (lm/W). This tells you how efficiently a light source converts electricity into light. A higher lm/W number means you get more light for your money. Think of it like fuel efficiency in a car. One car might go 30 miles on a gallon of gas, while a more modern, efficient car goes 50 miles. Both used one gallon, but one performed much better. Modern COB chips are like that highly efficient car. It's common for them to have efficacies over 130 lm/W, and some go much higher. This means they are brilliant at turning electricity into light and wasting very little as heat. As a manufacturer, I know that combining a high-efficacy COB chip with a high-quality driver is the secret to maximum performance. For a purchasing manager like Shaz, this translates directly to long-term savings for his clients, not just on electricity bills but also on maintenance, as efficient lights run cooler and last longer.

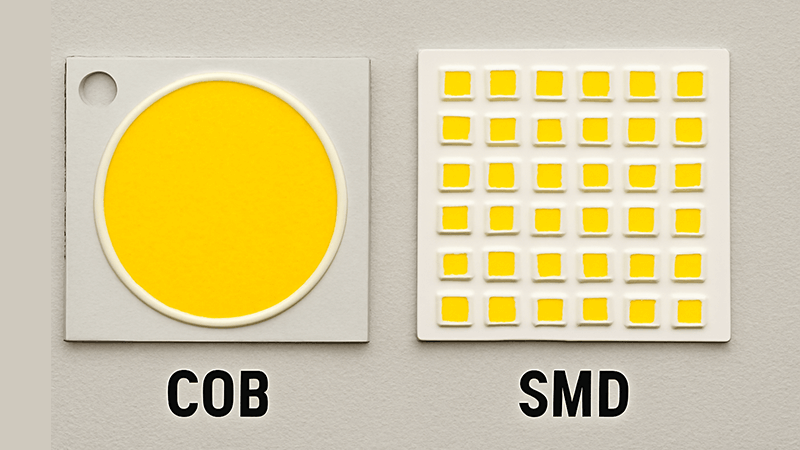

What is the difference between COB LED and normal LED?

The world of lighting is full of acronyms: LED, SMD, COB. It's confusing, and without a clear understanding, you can't be sure you are sourcing the best technology for the job.

The main difference is packaging. A "normal" LED, like an SMD (Surface Mounted Device), consists of many individual LED packages soldered onto a circuit board. A COB (Chip on Board) LED places many bare chips directly onto a single board, which then functions as one large light source.

Dive Deeper

While both are types of LEDs, the way they are constructed leads to very different visual and performance characteristics. Choosing the right one depends entirely on the application.

Structure and Light Appearance

If you look closely at an SMD fixture, like an LED strip light, you can see the individual points of light. They look like small, separate yellow squares on a circuit board. When turned on, you see a series of bright dots. This is why diffusers are often needed to create a smooth, even look. A COB, on the other hand, looks like a single, solid yellow circle or square when it's off. When you turn it on, the entire surface glows with a uniform, seamless light. There are no dots or hot spots. This single-source appearance is very similar to a traditional halogen bulb, which many designers and architects prefer for spotlighting applications. When I'm working with a designer who wants a perfectly smooth, dot-free line of light for a cove, I recommend our SMD strips. But when an architect needs to highlight a reception desk with a crisp, powerful beam, I always recommend a COB downlight.

Application and Performance

These structural differences make each technology ideal for different jobs. SMD is incredibly a versatile. Its dot-like nature makes it perfect for linear fixtures, LED tubes, and large panel lights where the light is spread over a wide area. Because the LEDs are spread out, heat is also more distributed.

COB technology shines brightest when you need high intensity from a small area. This makes it the champion for downlights, track lights, high bay lights, and retail spotlights. The ability to create a strong, controlled beam from a single point allows for dramatic and effective lighting. This is also why controlling glare with good optics, like the deep reflectors we discussed, is so important with COB. The choice is never about which technology is "better" in general, but which one is better for a specific task. For creating high-quality, comfortable, and powerful lighting in an office, COB is almost always the superior choice.

| Feature | COB (Chip on Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Structure | Many bare chips on one substrate | Individually packaged LEDs on a PCB |

| Light Output | Single, uniform, intense light source | Multiple, separate points of light |

| Best For | Downlights, spotlights, high bays | Strip lights, linear fixtures, bulbs |

| Heat Dissipation | Excellent (direct path to heatsink) | Good (through solder points and PCB) |

| Glare Potential | Higher, must be controlled with optics | Lower, naturally more diffused |

| Assembly | Simpler (one module) | More complex (many components) |

Conclusion

Choosing the right COB LED downlights with deep, anti-glare reflectors is key. This simple decision ensures a comfortable, efficient, and productive office that benefits everyone in the long run.

Explore the importance of heat management in LED lighting for longevity and efficiency. ↩

Find out the factors that lead to the extended lifespan of COB LED lighting solutions. ↩

Explore the differences between SMD and COB lighting technologies for better applications. ↩

Understand lumen density and its role in achieving effective and efficient lighting. ↩

Explore how COB LED downlights can transform your office lighting, enhancing productivity and comfort. ↩

Explore strategies to minimize glare in office lighting for a more comfortable workspace. ↩

Discover how deep anti-glare reflectors enhance lighting quality and reduce discomfort. ↩

Understand the significance of color accuracy in lighting and its effect on work performance. ↩

Learn about UGR and its importance in creating a comfortable office lighting environment. ↩

Discover how reflector depth affects light distribution and glare control in COB downlights. ↩

Learn about the impact of lighting on eye strain and how to mitigate it for better employee well-being. ↩

Find out how COB lights save energy while providing superior lighting performance. ↩

Learn about luminous efficacy and how it affects energy efficiency in lighting solutions. ↩