Dark, poorly lit hallways are a serious safety hazard. Every shadow can hide a potential trip, making navigation risky. COB LED downlights solve this by bathing corridors in clear, consistent light.

COB LED downlights significantly boost safety by producing a uniform, high-quality beam of light. This eliminates shadows and harsh glare, making it easier to see steps, obstacles, and elevation changes clearly. Their long-lasting reliability also ensures these critical areas are always safely illuminated.

When I started in this industry, the focus was just on making a light. Now, the focus is on how light affects our lives. Good lighting in a corridor or stairwell isn't a luxury; it's a fundamental part of a building's safety system. It's about preventing accidents before they happen. The technology we use to achieve this has come a long way. But how do you choose the right one? Let's break down why modern LEDs, especially COB downlights, are the best choice for these crucial spaces.

Is LED lighting a good choice for stairwells?

Old stairwell lights are often dim, flicker, and burn out quickly. This creates unsafe conditions and constant maintenance headaches. LED lighting is the clear, reliable, and cost-effective modern solution.

Yes, LED lighting is the best choice for stairwells. It delivers bright, instant-on illumination, which is critical for safety. LEDs also have incredibly long lifespans and use very little energy, drastically cutting maintenance and electricity costs compared to any older technology.

Over my years of manufacturing lighting, I've seen clients transform their properties just by upgrading stairwell lighting. The difference isn't just in the light quality; it's in the operational efficiency and peace of mind. Let’s look at the specific reasons why LED is the superior choice.

Energy Efficiency and Cost Savings

The first thing a purchasing manager like Shaz looks at is the cost. LEDs win here, every time. A traditional 60-watt incandescent bulb and an LED bulb can both light a stairwell landing, but their energy use is worlds apart. The LED might only use 9 watts to produce the same amount of light. When you have dozens or hundreds of these lights running for hours a day, the savings add up quickly. I always tell my clients to look at the Total Cost of Ownership, not just the upfront price of the bulb.

| Light Source | Typical Power Usage (per bulb) | Estimated Annual Energy Cost (12hrs/day) |

|---|---|---|

| Incandescent | 60W | ~$31.54 |

| CFL | 15W | ~$7.88 |

| LED | 9W | ~$4.73 |

These numbers show a clear story. The energy savings from LEDs pay for the upgrade in a very short time.

Durability and Low Maintenance

Stairwells can have high ceilings1, making light bulb changes difficult and expensive. You might need special ladders or even scaffolding. LED lights can last for 50,000 hours or more. That is over five years of continuous, 24/7 operation. For a light that is on for 12 hours a day, that lifespan extends to over 11 years. This dramatically reduces maintenance. You install them and forget about them. This "fit and forget" reliability is one of the biggest benefits I stress to project managers. It means fewer calls for maintenance teams and consistently safe, well-lit spaces.

Enhanced Safety Features

LEDs turn on to full brightness instantly. There is no warm-up time like with fluorescent bulbs. In an emergency or when someone enters a dark stairwell, you need light immediately, not 30 seconds later. LEDs also work perfectly in cold temperatures, where other types of lighting can fail. Furthermore, they are easily paired with motion sensors2 and other smart controls. You can have the lights at a low, energy-saving level and then instantly brighten them to 100% when someone enters the space. This combination of instant-on3, reliability, and control makes LEDs an unbeatable choice for stairwell safety.

What are the advantages of COB LED technology?

Standard LED lights can create multiple shadows and distracting bright spots. This uneven lighting can strain the eyes and hide hazards. COB technology4 fixes this by creating a single, flawless light source.

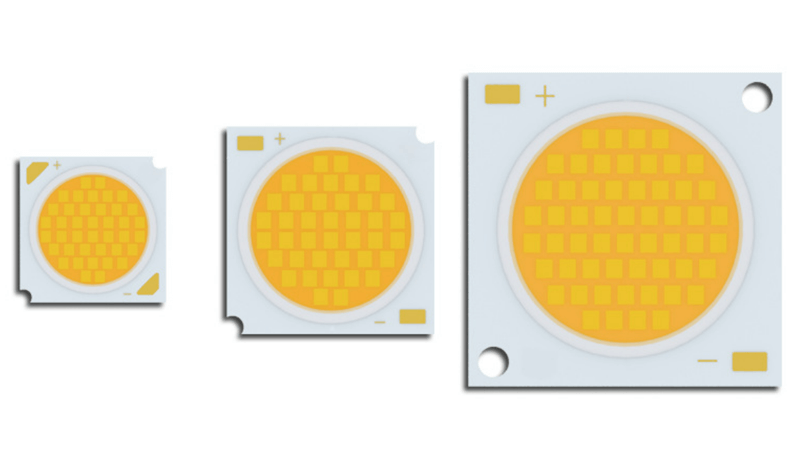

The main advantages of COB (Chip on Board) technology are its ability to produce a powerful, uniform beam of light5 without hotspots. This technology also offers better thermal management6 for a longer lifespan and higher efficiency, all within a more compact package.

When I first saw COB technology4, I knew it would be a game-changer for directional lighting like downlights. Before COB, we used arrays of SMD (Surface Mounted Device) LEDs. These are essentially many small, individual lights on a board. They are great for many applications, but for a clean downlight beam, they have weaknesses. COB technology solves these problems directly.

Superior Light Quality

The biggest advantage of COB is the quality of the light beam. Imagine shining several small flashlights at a wall—you get overlapping circles of light and multiple shadows. That's what an SMD downlight can do on a smaller scale. For a stairwell, these multiple shadows can create visual confusion on the treads, which is dangerous. A COB light source, on the other hand, has all the tiny LED chips packed so tightly together under a layer of phosphor that it acts as one large, single light source. The result is a clean, uniform, single-shadow beam. This is like the light from a traditional halogen bulb but with all the efficiency of an LED. This clean light is more comfortable for the eyes and much safer for navigating spaces.

Thermal Management and Longevity

This is a technical point, but it's crucial for anyone sourcing quality lighting. How a light handles heat determines its true lifespan and performance. COB LEDs bond the chips directly to a substrate like aluminum or ceramic, which is excellent at dissipating heat. Better heat management means a longer life and more stable performance.

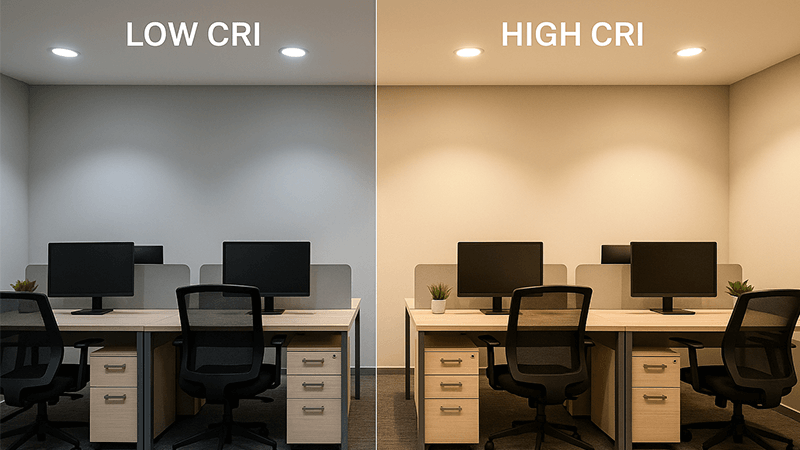

Here, quality really matters. A key component is the encapsulating gel that covers the LED chips. At my factory, we insist on using a gel with a temperature resistance of at least 200°C. Why? I've seen what happens with cheaper materials. If the gel can't withstand the heat, it will start to degrade and turn yellow. When this happens, the light's quality suffers badly. Specifically, the Color Rendering Index (CRI)7 can drop by over 10% in just 5000 hours. A light that started with a good CRI of 90 becomes a poor-quality light with a CRI below 80. Colors look washed out, and visibility is reduced.

| Encapsulant Quality | Temperature Resistance | CRI Degradation (after 5000 hrs) | Visual Result |

|---|---|---|---|

| High Quality | ≥200°C | < 2% | Stable, true colors, long life |

| Low Quality | <150°C | > 10% | Yellowing light, poor colors, short life |

A purchasing manager needs to know this. Asking a supplier about the temperature rating of their COB encapsulant is a great way to judge their commitment to quality.

How does quality LED lighting transform a space?

You walk into a hallway with buzzing, flickering lights and dull colors. The space feels dreary and unsafe. This is the effect of poor lighting. Quality LED lighting does the exact opposite.

Quality LED lighting transforms a space by making it feel safer, more comfortable, and more inviting. Through high color accuracy (CRI), low-glare optics, and flexible controls, it improves visual comfort8 and positively influences the mood and function of any area.

As a manufacturer, I believe my job is not just to sell lights, but to provide good experiences. The quality of light has a profound impact on how we perceive and use a space. In a corridor or stairwell, this impact is directly tied to safety and comfort. This goes far beyond just "making it bright enough."

The Importance of Color Rendering Index (CRI)

CRI measures how accurately a light source shows the true colors of objects, on a scale of 0 to 100. Sunlight has a CRI of 100. For years, the industry standard was a CRI of 80, which is acceptable. But to truly create a safe and comfortable space, I always recommend a CRI of 90 or higher. In a stairwell, a high CRI helps you better distinguish the edge of a step from the floor or see a spilled liquid on a patterned carpet. It provides more visual information. With a low CRI, colors can look flat and similar, which can mask subtle hazards. Insisting on a CRI of 90+ is a simple step that greatly enhances the visual safety of a space. It’s a detail that shows a commitment to quality.

Glare Control and Visual Comfort

Have you ever walked down a hallway and been blinded by the downlights in the ceiling? That's called glare, and it's not just uncomfortable; it's dangerous. When your eyes adjust to glare, your pupils constrict, making it harder to see into shadowed areas. This is a huge risk in stairwells. Quality COB downlights are designed with deep-set LEDs and precision optics to control glare. We measure this with a UGR (Unified Glare Rating). A low UGR (under 19 is considered very good for offices) means the light source is not distracting or disabling. When specifying lighting for corridors, asking for a low UGR is just as important as asking for the right brightness. It ensures the light helps you see, rather than hindering your vision.

Tunable White and Dimming

Modern LED systems offer incredible flexibility. "Tunable white" lighting allows you to change the color temperature of the light. You can set it to a crisp, cool white (like daylight) during the day to promote alertness, and a warm, soft white in the evening to create a more relaxed, welcoming atmosphere. This is another way lighting can enhance the experience of a space. When combined with dimming and motion sensors, you can create a sophisticated system that provides bright, safe light when the corridor is in use, and then dims down to a low, energy-saving level when it's empty. This provides safety, comfort, and maximum energy efficiency9.

What is the difference between a COB light and a downlight?

The terms "COB light" and "downlight" are often used, sometimes together. This can be confusing if you don't know the distinction. Getting it wrong can lead to buying the wrong product.

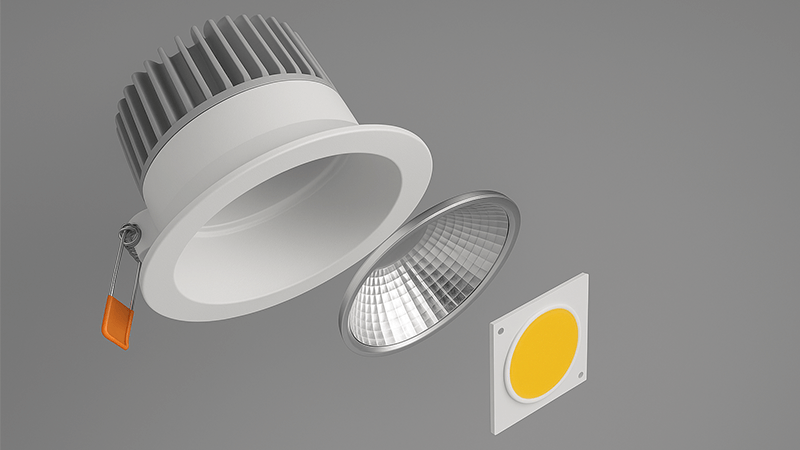

A "COB light" is the light engine—the technology that creates the light. A "downlight" is the fixture—the housing that directs the light downwards. Therefore, a COB downlight is a downlight fixture10 that uses a COB light engine.

To make the right purchasing decision, it's really important to understand the parts you are buying. When a client asks me for a "COB light," I always clarify if they mean just the component or the complete fixture. Let's break down these terms simply.

Understanding the Light Source: COB vs. SMD

The light source, or "light engine," is the part of the lamp that actually produces light. In modern LEDs, the two most common types used in downlights are SMD and COB.

- SMD (Surface Mounted Device): These are individual LED chips soldered onto a circuit board. When you look at an SMD light source, you can see the distinct points of light. They are very versatile but can create multiple shadows.

- COB (Chip on Board): These are multiple, tiny LED chips mounted directly onto a single substrate and covered with a uniform layer of phosphor. When you look at a COB source, it appears as a single, solid panel of light.

Here is a simple comparison:

| Feature | SMD (Surface Mounted Device) | COB (Chip on Board) |

|---|---|---|

| Appearance | Multiple visible dots of light | One single, uniform light panel |

| Light Beam | Can create multiple shadows, "spotty" | Single, clean shadow, uniform beam |

| Heat Dissipation | Heat comes from multiple points | Heat comes from a single, concentrated area |

| Best Application | Strip lights, linear lights, bulbs | Spotlights, downlights, track lights |

Understanding the Fixture: The Downlight

A downlight is a very common type of light fixture. Its name describes its function: it is a luminaire, usually recessed into a ceiling, that casts light in a downward direction. The fixture includes the housing, the trim, a reflector or lens to shape the light, and the electrical connections. The downlight is the total package that you install. A downlight is defined by its function and form factor, not by the type of light source inside it. You can have downlights that use old halogen bulbs, CFL bulbs, SMD LED arrays, or COB LED engines.

Putting It All Together: The COB Downlight

So, a "COB downlight" is simply a downlight fixture that is built around a COB light engine. This combination brings together the benefits of both parts. You get the clean, directional light from the downlight fixture form, and you get the powerful, high-quality, single-shadow beam from the COB light source. For applications like corridors and stairwells, where a clear, focused beam of high-quality light is needed to ensure safety and visibility, the COB downlight is often the best technical solution. It delivers professional-grade performance that other combinations struggle to match.

Conclusion

COB LED downlights11 are the best choice for corridor and stairwell safety. They provide uniform, high-CRI light that eliminates risks, while saving energy and maintenance costs for years to come.

Explore the difficulties of maintaining lighting in high-ceiling areas. ↩

Learn how motion sensors can improve safety and energy efficiency in lighting. ↩

Discover why instant-on lighting is crucial in emergency situations. ↩

Explore the benefits of COB technology for creating high-quality lighting. ↩

Discover the importance of uniform lighting in enhancing visibility and safety. ↩

Understand the significance of thermal management for LED longevity and performance. ↩

Explore how CRI affects color accuracy and visibility in various environments. ↩

Discover the relationship between lighting quality and visual comfort. ↩

Understand the energy-saving benefits of LED lighting compared to traditional bulbs. ↩

Learn about downlight fixtures and their role in effective lighting design. ↩

Explore how COB LED downlights enhance safety in poorly lit areas by providing uniform lighting. ↩