Tired of patchy lighting in your conference hall? Uneven light creates distracting shadows and glare1. COB LED downlights offer a powerful solution for perfectly uniform illumination.

COB (Chip-on-Board) LED downlights improve uniform lighting by using a single, high-density light source. This design produces a powerful, controlled beam that minimizes shadows and glare. The result is smooth, consistent illumination, which is perfect for large spaces like conference halls where clarity is essential.

I remember working with a client, Shaz from the UAE, on a large conference center project. He was a purchasing manager dealing with complaints about inconsistent lighting. The current setup created distracting hot spots and dark zones. We found that transitioning to COB downlights2 was the answer to his problem. But before you make a decision for your own project, it’s important to understand the full picture. Let's explore what makes these lights so special and what you need to look out for.

What are the advantages of COB lights?

Trying to find a light source that is both bright and compact? Older LEDs can be bulky and inefficient. COB technology3 packs incredible power into a small, simple design.

COB lights offer superior brightness from a compact source4, creating a high-quality, uniform beam. They are also highly efficient, have a longer lifespan5, and simplify the design and installation process because they combine many diodes into a single module. This reduces failure points and improves reliability.

To really understand the benefits of Chip-on-Board (COB) technology, it's helpful to compare it to the older Surface Mounted Device (SMD) technology. SMD lights use many small, individual LED chips mounted on a circuit board. Each chip is its own light source. This can create multiple shadows and a less uniform beam of light, which is not ideal for professional settings. COB technology, however, mounts many tiny diodes directly onto a single substrate, so they act as one large, powerful light source. This single point of light is the first major advantage.

Superior Light Quality and Density

Because all the light comes from one point, a COB LED with a good reflector produces a beautifully clean, uniform beam. There are no multiple shadows or pixelated effects. This is exactly what you need in a conference hall to ensure every attendee can see clearly without distraction. The density is also much higher. COB technology can pack more light sources into a smaller area. This high lumen density6 means you can get a very bright, powerful light from a surprisingly small fixture, which helps maintain a clean, minimalist ceiling aesthetic.

Simplified Design and Enhanced Reliability

From a manufacturing standpoint, which is my world, the simplified design is a huge plus. A COB fixture has one primary lighting module and two solder points. An equivalent SMD fixture might have 50 individual chips, each with at least two solder points. That's 100 points of potential failure compared to just two. This simplicity makes COB fixtures inherently more reliable. For a purchasing manager like Shaz, reliability means lower maintenance costs and fewer headaches over the lifespan of the installation. A more robust product is always a better long-term investment.

| Feature | COB (Chip-on-Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Light Source | Single, unified light source | Multiple, individual light sources |

| Beam Quality | Very uniform, clean beam | Can create multiple shadows |

| Light Density | Very high | Moderate to high |

| Solder Points | Minimal (usually 2) | Many |

| Reliability | Higher due to fewer failure points | Lower due to more components |

| Best Use Case | Downlights, spotlights (focused light) | Strip lights, area lighting (diffused light) |

What are the disadvantages of COB lights?

Worried about the potential downsides of new technology? COB lights seem perfect, but they have issues. If one part fails, the whole chip might go dark, creating headaches.

The main disadvantage is that if a single diode on the COB chip fails, the entire module must be replaced, unlike SMD LEDs where individual diodes can be repaired. They also generate concentrated heat that requires excellent thermal management7 and can have limited color-changing options.

As much as I advocate for COB technology, it's my responsibility to give my partners the full story. Every technology has trade-offs, and understanding them is key to making a smart purchase. When Shaz was considering COB downlights, we had a long discussion about these potential issues to make sure they were a good fit for his project's maintenance plan and budget.

Single Point of Failure

The greatest strength of COB—its single, unified chip—is also its main weakness. With SMD LEDs, if one or two chips fail, the others keep working, and the light output only drops a little. You can even sometimes replace the failed chip. With a COB LED, all the tiny diodes are part of one circuit. If a critical part of that circuit is damaged or one diode fails, the entire chip can go dark. You cannot repair it; you must replace the entire COB module. This can be more costly and inconvenient than fixing an SMD array, so it’s essential to choose COB products from a manufacturer with a reputation for quality and a low failure rate.

Concentrated Heat and Thermal Management

COB LEDs produce a lot of light from a very small area, which also means they produce a lot of heat in a very small area. This heat must be drawn away from the chip effectively, or the LED's lifespan and performance will suffer dramatically. This is why the heat sink is arguably the most critical component of a COB downlight. As a manufacturer, I know that the connection between the COB chip and the heat sink is vital. We use a thermal paste to fill any microscopic air gaps. From my factory experience, the thermal paste thickness needs to be controlled precisely, between 0.05–0.1 mm. If the layer is too thick, it actually works like an insulator, trapping heat and causing the chip to fail early. This is a small detail that makes a huge difference in product quality.

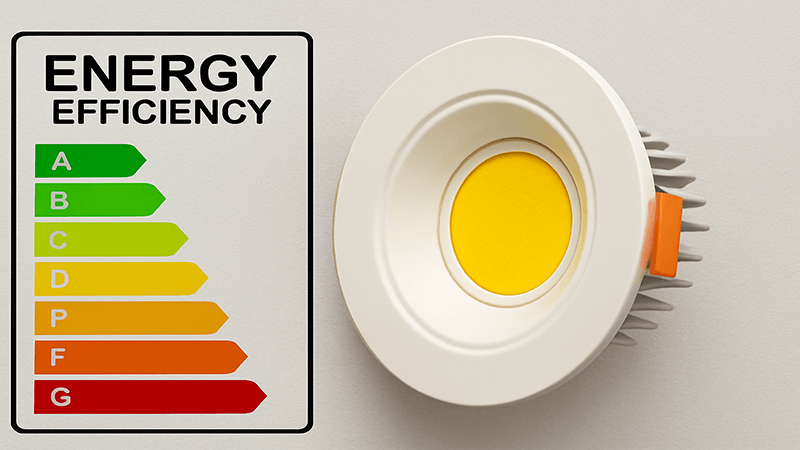

Are COB LEDs more efficient?

Is efficiency your top priority for lighting projects? You need maximum light for minimum energy. Outdated technologies waste money. COB LEDs offer a breakthrough in lumens per watt performance.

Yes, COB LEDs are generally more efficient than older technologies like SMD. They have a higher lumen-per-watt ratio due to their simplified design, reduced energy loss, and better thermal management. This means they produce more light while consuming less electricity, leading to significant energy savings8.

Efficiency is a top concern for any large-scale project, and rightly so. For the conference center project in the UAE, energy savings was a major factor for Shaz. The good news is that COB technology truly excels here, and there are a few clear reasons why.

Understanding Luminous Efficacy

The way we measure lighting efficiency is "luminous efficacy9," or lumens per watt (lm/W). Think of it like a car's fuel efficiency—you want the most output (lumens, or brightness) for the least input (watts, or energy). COB LEDs have a structural advantage that leads to better efficacy. The design of the chip results in a shorter heat-dissipation path compared to SMD. LEDs run more efficiently at cooler temperatures; a hot LED actually produces less light for the same amount of power. By getting heat away faster, a COB LED can maintain a higher lm/W ratio during operation.

System-Level Efficiency

A lighting fixture is more than just the LED chip. It's a system that includes the driver (which converts AC power to DC) and the optics (reflectors and lenses). A high-quality COB downlight considers efficiency at every stage. We pair our COB chips with high-efficiency drivers that minimize energy loss during power conversion. The single-point light source of a COB also allows for a more efficient optical design. A reflector can be designed to capture and direct almost all the light produced by the chip, whereas with a wide array of SMD chips, it can be harder to control all the light without losses. For my clients, I always stress that they should ask for the system efficacy, not just the chip's efficacy. A great chip with a poor driver is an inefficient light.

Here’s a general comparison to put it in perspective:

| Light Technology | Typical Luminous Efficacy (lm/W) |

|---|---|

| Halogen Bulb | 15–25 lm/W |

| SMD LED | 80–120 lm/W |

| COB LED | 100–150+ lm/W |

This data clearly shows the leap in performance. Choosing COB LEDs means lower electricity bills and a smaller carbon footprint, which are benefits every project manager can appreciate.

What are the disadvantages of downlights?

Considering downlights for your space? They look clean and modern. But improper planning can lead to a "cave effect10" with dark walls and a ceiling full of holes.

The main disadvantages of downlights are their fixed, downward beam, which can create dark ceilings and walls (the "cave effect"). They also require careful planning for placement to avoid shadows and achieve uniform coverage. Installation involves cutting holes in the ceiling, which can be permanent and complex.

Even with the best COB technology, the fixture style11 itself—the downlight—has its own set of challenges. It's important to be aware of these so you can plan your lighting design effectively. A beautiful, uniform pool of light on the floor or conference table is great, but not if the rest of the room feels dark and enclosed.

The "Cave Effect" and Glare

Downlights, by definition, direct light downwards. If you only use downlights, the light will primarily hit the floor and tabletops, leaving the upper parts of your walls and the ceiling itself in relative darkness. This can create a "cave effect10," making a room feel smaller and less inviting. In a conference hall, you want the entire space to feel bright and open. To solve this, a good lighting design must layer different types of light. I often advise clients to supplement downlights with other fixtures, like adjustable wall washers or gimbal downlights that can be tilted to illuminate vertical surfaces. This simple addition balances the light in the room and eliminates the cave effect.

Installation Complexity and Inflexibility

Installing recessed downlights is not a simple task. It requires cutting precise holes in the ceiling. You must consider what's above the ceiling: is there enough depth? Is there insulation that needs to be kept clear of the fixture? Are there fire rating requirements? For a large commercial project, this requires careful coordination with architects and contractors. Furthermore, once a downlight is installed, it is largely permanent. Moving it requires patching the old hole and cutting a new one, which is disruptive and costly. This lack of flexibility means the initial lighting plan is critical. I always recommend using lighting simulation software12 like DIALux. This allows us to map out the placement and spacing of every single downlight to ensure perfect coverage before anyone ever drills a hole. Getting it right the first time is everything.

Conclusion

COB LED downlights13 offer superior uniform lighting14 for conference halls, but success depends on managing their drawbacks. Proper planning and quality components are key to a professional, efficient installation.

Find out techniques to reduce shadows and glare for a better lighting experience. ↩

Learn about the pros and cons of using downlights in various settings. ↩

Explore the unique advantages of COB technology for modern lighting applications. ↩

Understand the benefits of using compact light sources in modern lighting solutions. ↩

Explore factors that enhance the longevity of COB LED lighting solutions. ↩

Discover how lumen density affects lighting efficiency and quality. ↩

Learn about the critical role of thermal management in maintaining LED performance. ↩

Find out how COB LEDs can significantly reduce energy consumption and costs. ↩

Learn about luminous efficacy and its importance in evaluating lighting efficiency. ↩

Understand the cave effect and how to avoid it in your lighting plans. ↩

Understand the impact of fixture style on overall lighting effectiveness. ↩

Discover how lighting simulation software can optimize your lighting design. ↩

Explore the advantages of COB LED downlights for achieving uniform lighting in large spaces. ↩

Learn effective strategies for creating uniform lighting that enhances visibility and comfort. ↩