Are your LED downlights failing sooner than expected? You invest in quality lighting, but premature dimming and outright failure can damage your reputation and increase costs, leaving you frustrated.

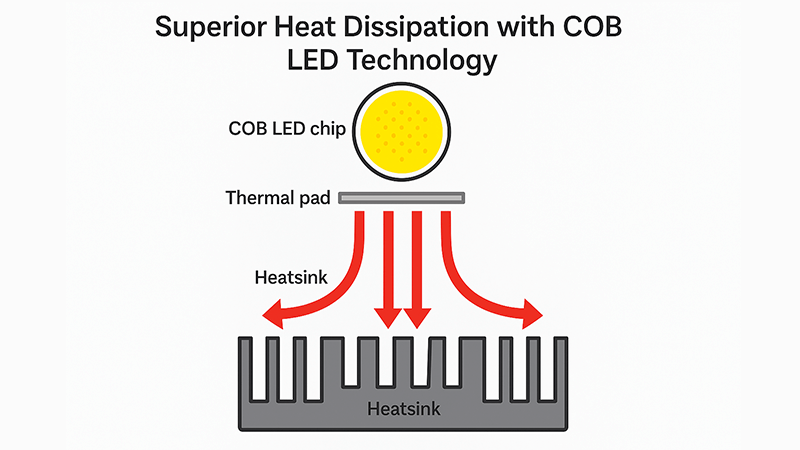

COB (Chip-on-Board) packaging dramatically improves heat dissipation. It mounts LED chips directly onto a substrate with high thermal conductivity. This creates a superior, direct path for heat to escape to the heatsink, lowering operating temperatures and extending the life of the downlight.

I've been in the LED lighting business for a long time, starting on the factory floor. Over the years, I've seen countless products succeed or fail based on one critical factor: heat management. A brilliant design means nothing if the light burns out in six months. That's why understanding how technology like COB deals with heat is so important for professionals like you. It's the key to sourcing reliable products that keep your clients happy and your projects shining for years. Let’s explore why COB is a game-changer for thermal performance.

What is COB in LED lighting?

You see "COB" on specification sheets and hear it in sales pitches. But not fully grasping what makes it different can leave you uncertain, possibly leading to choosing the wrong product.

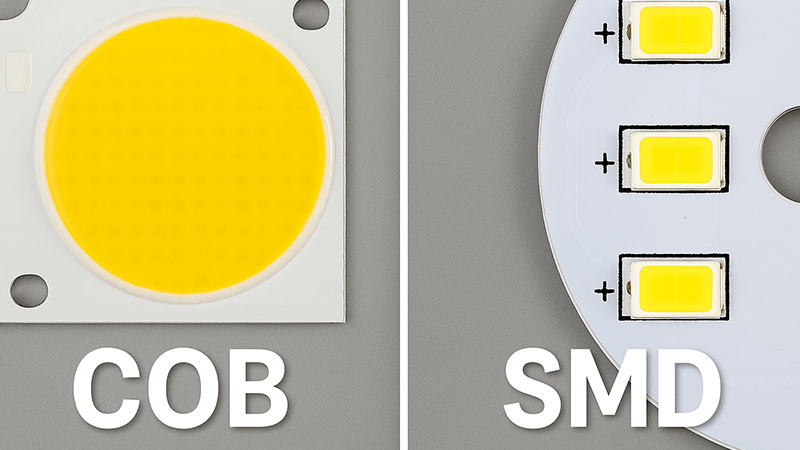

COB, or Chip-on-Board, is a packaging method where multiple bare LED chips are mounted directly onto a single substrate, like aluminum or ceramic. This creates one large, uniform light-emitting module, unlike older technologies that relied on many individual packaged LEDs.

To really get what makes COB technology special, it helps to compare it to what came before, mainly SMD (Surface Mount Device) LEDs1. With SMD, each individual LED chip is encased in its own little plastic package with leads, and then these packages are soldered onto a circuit board. You get a lot of separate points of light. I remember early LED projects where you could see these individual dots of light, what we called the "polka dot effect." For a purchasing manager like Shaz in the UAE, who works on high-end commercial projects2, that look just wasn't acceptable.

When we switched to COB for our downlights, the difference was immediate. Because all the tiny chips are packed together on one board and covered by a single phosphor layer, you get one smooth, consistent beam of light. It looks much more like the single-source light from a traditional halogen bulb, which architects and designers love.

COB vs. SMD: A Structural Look

The real magic of COB, especially for heat dissipation3, is in its simple, direct structure. Let's break down the differences.

| Feature | SMD (Surface Mount Device) | COB (Chip-on-Board) |

|---|---|---|

| Structure | Individual chips in plastic packages soldered to a PCB. | Bare chips bonded directly onto a metal/ceramic substrate. |

| Light Output | Multiple points of light. Can create glare or spots. | Single, uniform, and consistent light source. |

| Heat Path | Chip -> Solder -> Package -> Solder -> PCB -> Heatsink | Chip -> Substrate -> Heatsink |

| Thermal Resistance | Higher due to multiple layers and materials. | Lower due to a more direct, simplified thermal path4. |

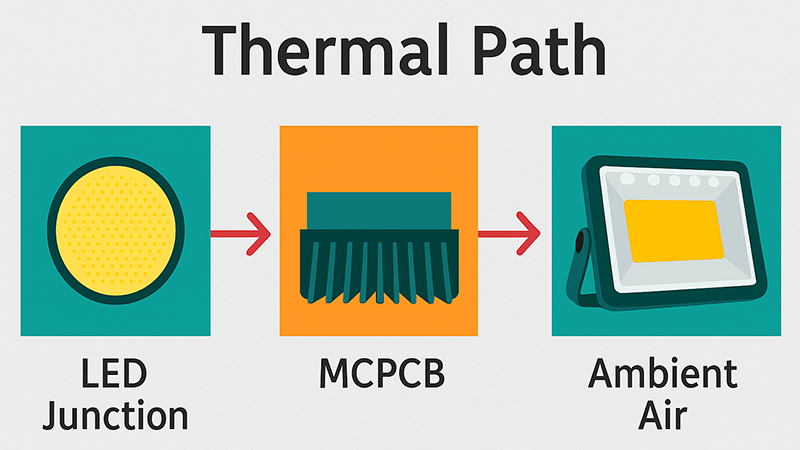

As you can see from the table, the heat from an SMD LED has to travel through many different layers before it even gets to the main heatsink5. Each layer adds a little bit of resistance, trapping heat. With COB, the heat has a much shorter, more efficient path. It goes directly from the chip to the high-conductivity substrate6 and then straight to the heatsink. This simpler path is the foundation of COB's superior thermal performance.

Does COB light generate heat?

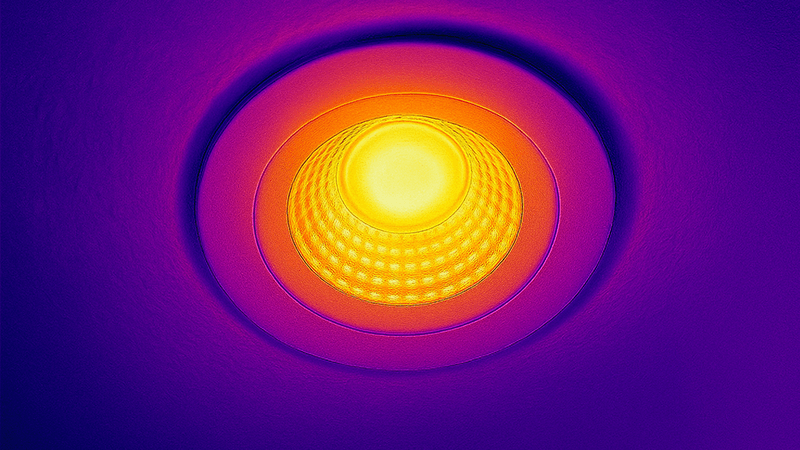

You've probably been told that LEDs are "cool" lighting. But then you touch a running LED downlight7 and notice it's quite hot, which can be confusing and cause you to question its longevity.

Yes, COB LEDs definitely generate significant heat. While far more efficient than old bulbs, a large portion of electricity—sometimes up to 70%—is converted into heat, not light. This heat is the primary enemy of an LED's lifespan and must be managed effectively.

It's one of the biggest misconceptions in our industry. "Energy-efficient" does not mean "heat-free." The physics is simple: when electricity passes through the LED semiconductor, it excites electrons. When these electrons fall back to a lower energy state, they release energy. Some of this energy becomes light (photons), and the rest becomes heat. High-quality LEDs are better at converting energy to light, but no LED is 100% efficient. Because COB packs so many chips into a small area, it actually concentrates a lot of heat in one spot. So, while COB technology is great, it makes a proper heat dissipation system even more critical.

Why Managing Junction Temperature is Crucial

The most important metric here is the "junction temperature," or Tj. This is the temperature right at the p-n junction inside the LED chip where light is created. The entire goal of a good thermal management8 system, from the COB substrate to the heatsink, is to keep this junction temperature9 as low as possible. If the Tj gets too high, several bad things happen very quickly.

First, the efficiency drops. A hotter LED produces less light for the same amount of power. Second, the color of the light can change, a phenomenon called color shift10. A warm white light might start to look greenish or bluish, which is a disaster for any architectural project where color consistency is key.

The biggest problem, however, is a drastic reduction in lifespan. The industry standard "L70" rating, which is the time it takes for a light to dim to 70% of its initial output, is directly tied to junction temperature. A small increase of just 10-15°C in the junction temperature can cut the lifespan of an LED in half. This is why when a client complains about a downlight failing after only a year or two, my first suspect is always poor heat dissipation. The LED chip was essentially cooked from the inside out.

Do COB LEDs need a heatsink?

You might see a compact COB module and wonder if its advanced design means it doesn't need a bulky heatsink. This assumption could lead to specifying a product with an inadequate thermal system.

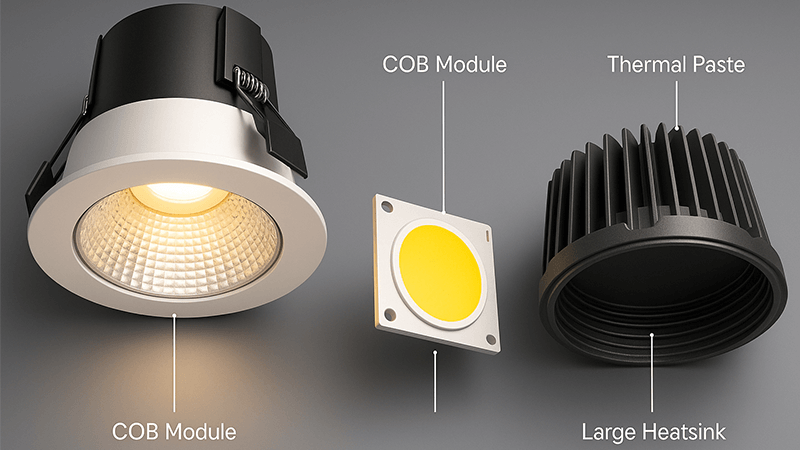

Absolutely, yes. A heatsink is not optional; it is an essential component for any COB LED application. The high concentration of heat generated by the COB module requires an effective heatsink to draw that heat away and dissipate it into the surrounding air.

Thinking a COB LED can work without a heatsink is like thinking a high-performance engine can run without a radiator. It will work, but only for a very short time before it overheats and destroys itself. The COB module is brilliant at getting heat off the chip, but that heat needs somewhere to go. The heatsink's job is to provide a large surface area for this heat to be transferred to the air through convection. Without it, the heat would just build up on the COB's substrate, the junction temperature would skyrocket, and the LED would fail rapidly.

In my experience, the quality and design of the heatsink are just as important as the quality of the LED chip itself. At iPHD, we don't cut corners here.

Heatsink Design and Material Choices

When evaluating a downlight, the heatsink is one of the first things I look at. You can tell a lot about a manufacturer's commitment to quality from their heatsink design.

A good heatsink needs two things: high thermal conductivity11 and a large surface area. The fins on a heatsink are not just for looks; they are engineered to maximize the surface area that is in contact with the air, allowing heat to escape more efficiently. The more complex and numerous the fins, the better the cooling capacity, generally speaking.

But the material is even more fundamental. The most common material for high-quality die-cast heatsinks is an aluminum alloy. However, not all aluminum is the same. We insist on using ADC12 aluminum12 for our heatsinks. I learned this the hard way years ago. We had a batch of downlights from another supplier that were failing. When we tested them, we found the heatsinks were made from a cheaper aluminum alloy. The material simply couldn't pull the heat away fast enough.

Here’s why it matters:

- ADC12 Aluminum: Has a thermal conductivity of ≥96 W/m·K (watts per meter-Kelvin). This is a good standard for effectively pulling heat away from the COB module.

- Cheaper Alloys: Can have a thermal conductivity of half that or even less. With such low conductivity, the heatsink itself becomes a bottleneck, and the fins can't dissipate heat they never receive.

This is a detail that I always stress to purchasing managers like Shaz. You must ask your supplier what material they use for the heatsink. If they can't give you a straight answer, it's a major red flag. It’s an easy place for a factory to cut costs, but it compromises the entire product.

How to reduce heat from LED lights?

You know heat is the enemy of LEDs. But as a buyer, you need practical ways to ensure the products you source are designed to last, protecting your investment and reputation.

To reduce heat, focus on the entire thermal path: a quality COB with a low-resistance substrate, effective thermal interface material (TIM)13, and a large, high-conductivity heatsink made from a material like ADC12 aluminum. Proper installation is also key.

Reducing heat isn't about one magic component; it’s about optimizing an entire system. I think of it as a chain. The chain is only as strong as its weakest link. For an LED downlight, that chain is the path the heat takes from the chip to the air. At my company, Upward Lighting, this is our obsession. We analyze every single link in that chain to make sure there are no weak spots. A failure at any point—a cheap COB substrate, poor thermal paste14, or an undersized heatsink—and the whole system fails.

As someone responsible for sourcing, understanding these links empowers you to ask the right questions and identify well-engineered products.

Optimizing the Entire Thermal Path

Let's walk through the heat's journey step-by-step and see where quality matters.

-

The COB Substrate: The journey starts here. The COB module itself must be built on a substrate with high thermal conductivity11. Ceramic substrates are excellent but more expensive. High-grade aluminum Metal Core Printed Circuit Boards (MCPCB) are a very effective and common choice. A low-quality substrate will trap heat right at the source.

-

The Thermal Interface Material (TIM): This is the unsung hero of heat dissipation. The TIM is the paste or pad that sits between the COB module and the heatsink. Its only job is to fill in the microscopic air gaps between the two surfaces. Air is a terrible conductor of heat, so even a tiny gap can stop heat transfer. A high-quality thermal paste ensures a seamless connection. We once had a project where the client specified a specific high-end COB, but the lights were still underperforming. We disassembled one and found the factory had used a cheap, silicone-based TIM that had dried out. We replaced it with a quality silver-based paste, and the operating temperature dropped by 10°C.

-

The Heatsink: As we discussed, this is the radiator. Its design and material are critical. You need to ensure it's made from a high-conductivity material like ADC12 aluminum (≥96 W/m·K) and has enough surface area (fins) to effectively dissipate the heat load of the COB. Don't be fooled by heavy but simple-looking heatsinks. A well-engineered, finned design is often lighter and far more effective.

-

The Driver: Don't forget the power supply15! The driver also generates heat. In well-designed downlights, the driver is either located remotely or is thermally isolated from the LED module so they don't heat each other up.

-

Installation Environment: Finally, how the downlight is installed matters. A fixture packed tightly with insulation in a hot ceiling with no airflow will run much hotter than one with room to breathe. Always follow the manufacturer's installation guidelines.

By scrutinizing each of these five points, you move from simply buying a product to investing in a reliable lighting solution.

Conclusion

In short, COB technology excels at moving heat off the chip, but its effectiveness depends entirely on a well-designed thermal path, especially a high-quality ADC12 aluminum heatsink.

Understand the differences between SMD and COB LEDs to make informed purchasing decisions. ↩

Explore the unique challenges faced in high-end commercial lighting and how to overcome them. ↩

Explore how effective heat dissipation can enhance the lifespan and efficiency of LED lights. ↩

Understanding the thermal path can help you optimize LED performance. ↩

Find out why a proper heatsink is critical for the performance of COB LED lights. ↩

Discover the importance of substrate materials in LED heat management. ↩

Get tips on choosing LED downlights that will perform well and last longer. ↩

Learn about thermal management techniques to ensure your LED lights perform optimally. ↩

Understanding junction temperature is crucial for maintaining LED performance and longevity. ↩

Learn about color shift and how it can affect the quality of your lighting projects. ↩

Learn how thermal conductivity affects the efficiency and lifespan of LED lights. ↩

Learn why ADC12 aluminum is preferred for heatsinks in LED applications. ↩

Explore the role of TIM in enhancing heat transfer in LED lighting systems. ↩

Find out how thermal paste can improve heat dissipation in LED systems. ↩

Learn how the power supply can influence the heat generation in LED systems. ↩