Struggling with lighting that's either too bright or too dim? You want to set the perfect mood, but static lights offer no control. Dimmable COB downlights provide the simple, flexible solution you need.

Dimmable COB LED downlights offer superior lighting flexibility by allowing you to precisely control brightness levels. This turns a single fixture into a multi-functional tool, perfect for bright task lighting, creating soft ambient glows, and adapting any space to different activities and times of day.

Having the power to adjust your lighting completely changes how you use a room. It’s one of the most effective ways to add value and function to a space. But before you commit to them for your next project, you might wonder how they actually work and what you need to know to get it right. I've spent my career in the LED lighting industry, and I want to share my knowledge to help you avoid common mistakes and choose the best products. Let's dive deeper into the details.

How do dimmable downlights work?

You want the benefits of dimming but worry about technical problems. Incompatible dimmers and drivers can lead to flickering, buzzing, or poor performance. Understanding the basics is the first step to success.

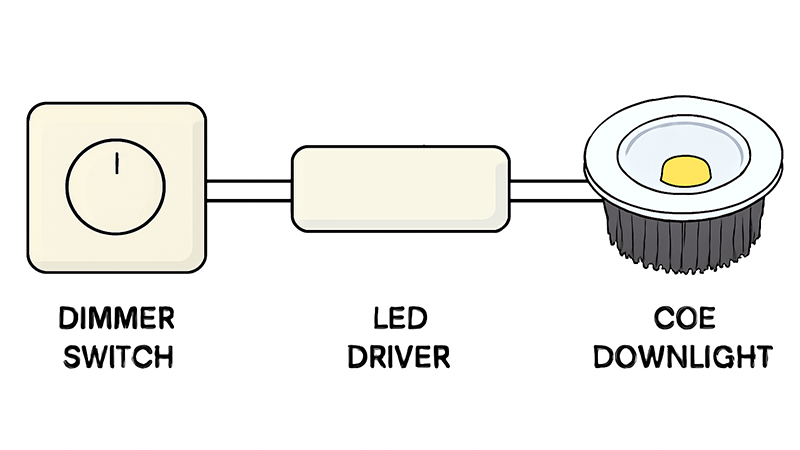

Dimmable LED downlights operate using a special component called a driver, which regulates the electrical current sent to the LED. When you adjust a compatible wall dimmer, it signals the driver to either increase or decrease the current, resulting in a smooth change in the light's brightness.

It’s a common mistake to think that dimming an LED is like dimming an old incandescent bulb. With old bulbs, you just reduced the voltage. LEDs are more complex. They are low-voltage devices that need a constant, controlled current. The real magic of a dimmable LED downlight is in its driver. The driver is the brain of the operation. It takes the main power from your building and converts it into the specific current that the LED needs to light up. For dimming to work, the wall dimmer switch and the LED driver must speak the same language. This "language" is called a dimming protocol1. Choosing the wrong one is where most problems begin. I once worked with a purchasing manager who sourced beautiful lights for a new office building, but the TRIAC dimmers2 he specified were not fully compatible with the drivers. The result was an annoying flicker across half the office. We solved it, but it was a costly lesson in checking compatibility first.

Key Dimming Protocols You Should Know

The protocol determines how the dimmer communicates with the driver. There are three main types you will encounter in the market. Understanding them is key to specifying the right products for your project.

| Dimming Protocol | Best For | How It Works | Key Consideration |

|---|---|---|---|

| TRIAC | Residential projects, retrofits | Reduces power by "cutting" the AC sine wave. Uses standard 2-wire installation. | Can cause buzzing or flickering if the driver isn't high quality. |

| 0-10V | Commercial spaces, new installations | A separate pair of low-voltage wires sends a signal from 0V (off) to 10V (100%). | Requires extra 2-core wiring. Offers very smooth performance. |

| DALI | Large smart buildings, premium projects | A digital signal gives individual control and feedback for each light. | Most complex and expensive, but offers ultimate control and data. |

When you're sourcing lights, always confirm the dimming protocol of the driver and ensure you are matching it with a dimmer switch that uses the same protocol. This simple check will save you from major headaches down the line.

Can COB LED be dimmable?

You see "COB LED" and wonder if this technology is compatible with dimming. You don't want to invest in powerful, high-quality lights only to find out they can't be controlled.

Yes, COB (Chip on Board) LEDs are fully dimmable. The ability to dim is not determined by the COB chip itself, but by the external LED driver it is paired with. As long as the COB downlight is equipped with a dimmable driver, it will dim smoothly.

This is a question I get a lot from clients, especially those new to COB technology. The COB chip is simply the light engine—a high-density array of LEDs packaged together as a single module. It produces a powerful, uniform beam of light. On its own, a COB chip is just waiting for instructions. Those instructions come from the LED driver. If you connect a COB chip to a non-dimmable driver, it will only operate at 100% brightness. If you connect that exact same COB chip to a dimmable driver3 (like a TRIAC, 0-10V, or DALI version), it becomes a fully controllable, dimmable light source. This is what makes COB lighting so versatile. You can use the same high-performance light fixture for different applications just by changing the driver.

Why COB is a Great Choice for Dimmable Lighting

COB technology offers some clear advantages when it comes to dimming, which is why it's a preferred choice for many high-end applications. As a manufacturer, I've seen how these benefits translate into better performance for my clients. The key is in how the light is produced.

- Smooth Light Output: Because a COB is a single, large light source, it doesn't create multiple shadows or hotspots like some arrays of separate SMD LEDs can. When you dim a COB light, the entire beam dims uniformly, giving a very clean and natural effect.

- Color Consistency: High-quality COB LED4s are designed to maintain their color temperature (CCT) very well, even at low dimming levels. This is known as color stability. Cheaper LEDs can sometimes shift in color, appearing more green or pink when dimmed. When I was developing my first line of architectural downlights, I spent months testing different COB chips to find one that held its warm 3000K color perfectly, all the way down to 1% brightness. Consistency is a mark of quality.

- High Efficacy: COB LEDs are very efficient at turning electricity into light. This efficiency remains strong even when dimmed, which means they are great for saving energy, which we'll discuss next.

So, when you are sourcing COB downlights, the question isn't "is the COB dimmable?" but rather, "what kind of dimmable driver is it paired with?" Always ask the supplier to specify the driver type and protocol to ensure it matches your project's control system.

Do dimmable LED lights use less energy when dimmed?

You are focused on energy efficiency5 and reducing operational costs. You wonder if dimming your lights actually translates into real energy savings6 or if it's just a feature for ambiance.

Yes, dimmable LED lights absolutely use less energy when they are dimmed. The power consumption is directly related to the light output. When you dim an LED to 50% of its brightness, you are using roughly 50% of the electricity, leading to significant energy savings.

This is one of the biggest functional benefits of using dimmable LEDs, and it's a powerful selling point for any project. Unlike older technologies where dimming was very inefficient, LEDs have a mostly linear relationship between power and brightness. When the driver reduces the current to the LED chip to make it dimmer, it also draws less power from the wall. This is a huge advantage for commercial spaces7 like offices, hotels, or restaurants where lights are on for many hours a day. Think about a restaurant setting. During the busy lunch rush, you might need the lights at 100% brightness. But in the evening, you dim them down to 30% to create a more intimate atmosphere. For all those hours, you are saving approximately 70% on your lighting energy costs8 for that area.

Understanding the Savings in Practice

To really see the impact, let's look at a simple example. I was once consulting for a client in the UAE, a facilities manager for a chain of retail stores. They were hesitant about the higher initial cost of dimmable systems until I broke down the numbers for them.

Let's compare a standard 15W non-dimmable downlight with a 15W dimmable COB downlight.

| Scenario | Non-Dimmable 15W Downlight | Dimmable 15W Downlight |

|---|---|---|

| Operating Hours | 12 hours/day (100% brightness) | 4 hrs at 100%, 8 hrs at 40% |

| Daily Power Use | 15W x 12h = 180 Wh | (15W x 4h) + (15W x 40% x 8h) = 60 Wh + 48 Wh = 108 Wh |

| Daily Energy Savings | - | 40% Savings |

| Annual Savings/Light | - | (180 Wh - 108 Wh) x 365 days / 1000 = 26.28 kWh |

When you multiply that annual saving by hundreds or thousands of fixtures across multiple locations, the financial benefit becomes massive. It not only pays back the initial investment in the dimming system but also significantly reduces the building's overall operating costs for years to come. Dimming is not just about creating a mood; it's a smart business decision.

Do COB lights get very hot?

You know that heat is the enemy of an LED's lifespan and performance. You see how bright and powerful COB lights are and worry that they must generate a lot of heat, potentially causing failures.

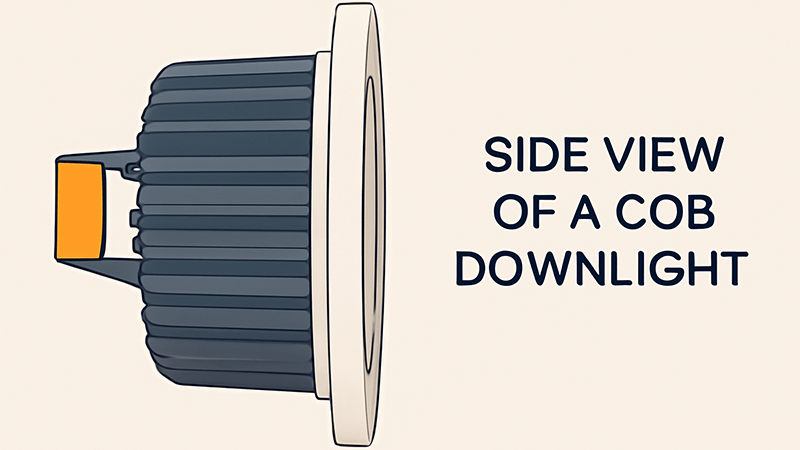

All LEDs produce heat, and because COB LEDs pack a lot of power into a small area, managing that heat is critical. A well-designed COB downlight will have a substantial heat sink to dissipate this heat effectively, ensuring a long lifespan and stable performance.

This is a valid concern and one that separates high-quality manufacturers from low-quality ones. Heat is a byproduct of the process that creates light inside the LED chip. If that heat is not drawn away from the chip, the chip's temperature will rise. This can cause two major problems: the light output will decrease, and the lifespan of the LED will be dramatically shortened. Because a COB LED has many individual chips densely packed together, it creates a concentrated point of heat. This makes the design of the heat sink9—the metal component that absorbs and dissipates the heat—incredibly important. You can often judge the quality of a COB downlight just by looking at its heat sink.

What Makes a Good Heat Sink?

From my experience in manufacturing, I know that the heat sink is not just a piece of metal; it is an engineered thermal management10 system. Its design and material are crucial for the long-term health of the light fixture.

- Material: The best heat sinks are made from aluminum, specifically die-cast or cold-forged aluminum. Aluminum has excellent thermal conductivity, meaning it pulls heat away from the COB chip very quickly. Poor quality lights might use cheaper metals or even plastic, which is a major red flag.

- Surface Area: Heat is dissipated into the surrounding air. The more surface area the heat sink has, the more effectively it can release heat. This is why you see so many cooling fins on good quality downlights. A larger, heavier heat sink is usually a good sign. When I'm designing a new product, I run thermal simulations to optimize the fin design for maximum airflow and cooling.

- Thermal Connection: There must be a perfect connection between the COB chip and the heat sink9. We use a special material called a Thermal Interface Material (TIM) to fill any microscopic air gaps. A poor connection here means heat gets trapped, and the LED will fail prematurely.

So, while COB lights do generate heat, a well-built fixture is designed to handle it perfectly. When you're evaluating samples, pay attention to the weight and build quality of the fixture. Pick it up. A solid, heavy light with a large, well-designed aluminum heat sink is a product built to last.

Conclusion

Dimmable COB downlights provide unmatched flexibility, efficiency, and quality of light. By understanding how they work and choosing compatible, well-designed products, you can transform any space while also achieving significant energy savings.

Get insights into various dimming protocols and their applications in lighting. ↩

Explore the functionality of TRIAC dimmers and their compatibility with LED lights. ↩

Understand the role of a dimmable driver in achieving smooth lighting control. ↩

Explore the advantages of COB LED technology for high-quality lighting solutions. ↩

Learn how dimmable LEDs contribute to energy savings and sustainability. ↩

Learn about the significant energy savings achievable with dimmable LED systems. ↩

Discover the advantages of dimmable lighting in enhancing commercial environments. ↩

Understand how dimming can lead to substantial reductions in lighting energy expenses. ↩

Discover how heat sinks enhance the performance and lifespan of LED lights. ↩

Explore effective thermal management strategies for optimal LED performance. ↩