Installing downlights creates ceiling holes, a major fire risk. A fire could spread rapidly through these gaps. Fire-rated downlights seal these openings, crucially protecting lives and property.

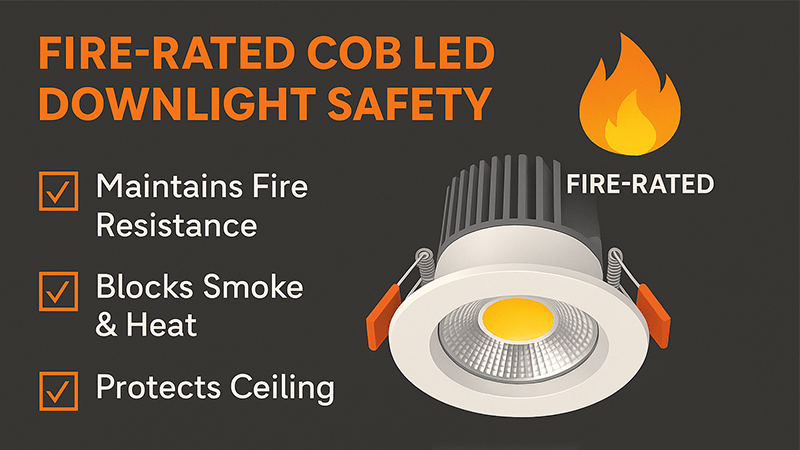

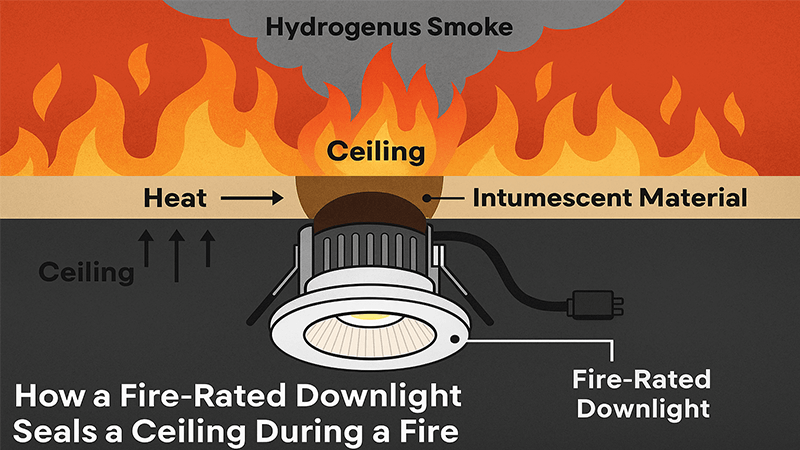

Fire-rated COB LED downlights enhance building safety by sealing the holes cut into ceilings for their installation. During a fire, special intumescent material in the light fixture expands, blocking the passage of fire and smoke. This containment maintains the ceiling's fire barrier for crucial evacuation time.

In my years of manufacturing lighting, I've seen how a small component choice can have a massive impact on safety. The difference between a standard and a fire-rated downlight is not just a feature; it's a critical life-saving measure. Many people don't fully understand what makes these lights so effective or what to look for to ensure genuine protection. Let's look deeper into how these essential fixtures work and why they are non-negotiable for safe building design.

Why use fire rated downlights?

Standard downlights compromise your ceiling's fire barrier1. This allows fire and smoke to spread between floors in minutes. Using fire-rated downlights2 restores this barrier, containing the danger and keeping people safe.

You must use fire-rated downlights to maintain the fire resistance integrity3 of a ceiling after installation. They restore the fire barrier that was breached by cutting a hole, preventing the rapid spread of fire and smoke. This is a critical safety measure and often a legal requirement.

When we talk about using fire-rated downlights, we're talking about maintaining a building's designed safety systems. It’s not just about the light itself, but about how it interacts with the structure around it. For a purchasing manager like Shaz in Dubai, understanding this principle is key to sourcing truly compliant and safe products for large-scale projects.

Restoring a Ceiling's Fire Integrity

Most modern buildings use ceilings made from materials designed to resist fire for a specific period, such as 30, 60, or 90 minutes. This rating gives occupants time to evacuate and helps prevent the building's structure from collapsing. However, the moment you cut a hole in that ceiling to install a standard downlight, you create a direct pathway for fire and deadly smoke. The entire fire rating of that ceiling is now compromised. A fire-rated downlight is specifically designed to solve this problem. It contains a band of intumescent material4. In the event of a fire, the intense heat causes this material to expand dramatically, completely sealing the hole and the back of the fixture. This action effectively restores the ceiling's original fire barrier, containing the fire to its point of origin for the rated time.

The Real-World Impact on Safety and Compliance

The practical benefit is invaluable: you are buying time. By preventing fire from spreading through the ceiling void to the floor above, you give people more time to escape. You also help contain the fire to a smaller area, which can significantly reduce property damage and make the fire easier for emergency services5 to control. I remember a conversation with a contractor who initially wanted to use cheaper, non-fire-rated lights for a residential tower. I explained that if a fire started in one apartment, the non-rated fixtures would act like vents, channeling flames and smoke into the apartment above in just a few minutes. This not only puts more lives at risk but could also lead to legal liability6 and a failed building inspection. Using certified fire-rated downlights is the only way to ensure compliance and, more importantly, protect the people inside.

What building regulations cover fire rated downlights?

Are you unsure about the maze of fire-rated lighting regulations7? Using a non-compliant product can lead to failed inspections, costly rework, and serious legal risks. Understanding the key standards is essential.

Key building regulations include the British Standard BS 476-218, which tests the fire resistance of structural elements. Products must also comply with local fire safety codes9, like Part B in the UK or directives from the UAE Civil Defence, and carry appropriate certification like a CE mark.

Navigating regulations can be complex, especially for international projects. From my factory floor, I see products destined for countries all over the world, each with its own specific rules. For a professional like Shaz, specifying a product that meets both internationally recognized standards and local UAE requirements is crucial for a project's success and safety. It’s about more than just a sticker; it's about verified, tested performance that you can depend on when it matters most.

Key International Standards to Know

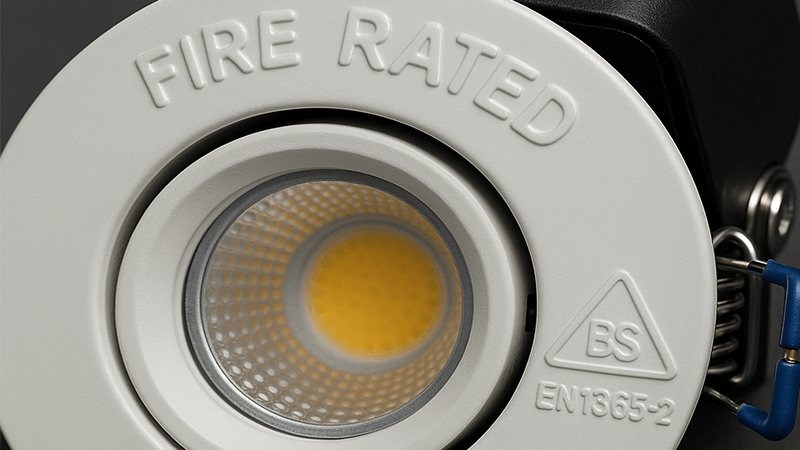

When sourcing fire-rated downlights, there are a few globally recognized standards that indicate a product has been properly tested. A primary one is BS 476-21: Fire tests on building materials and structures. This British Standard is a performance-based test. It doesn't certify the downlight itself, but rather the entire structure (like a specific type of ceiling joist and plasterboard) with the downlight installed. The test measures how long the complete system maintains its integrity against fire. This is why you see ratings of 30, 60, or 90 minutes. Another important one is BS EN 1365-2, which is the European equivalent. Products sold in the European Economic Area must also have a CE mark10, which shows they meet health, safety, and environmental standards. For a fire-rated downlight, this mark implies it won't fail dangerously, but it is the BS 476 test report that proves its fire-stopping performance.

Local Regulations and Due Diligence

While international standards provide a strong baseline, local building codes are the final authority. In the UAE, for example, the UAE Fire and Life Safety Code of Practice11 is managed by the Civil Defence of each Emirate. These codes are extremely detailed and must be followed precisely. A product might have a European test report, but it must also be approved or listed by the local authorities to be used in a project. As a manufacturer, we often work with clients like Shaz to provide all necessary documentation—test reports, certificates of conformity, and technical data sheets—to get our products approved by the Dubai Civil Defence (DCD) or Abu Dhabi Civil Defence (ADCD). Your due diligence as a buyer is to not only ask for the certificate but to verify it is current and applicable to the specific building structure in your project. Always cross-reference the product with local requirements.

Are LED lights less of a fire hazard?

People often think LEDs are perfectly safe because they run cooler. While they are a big improvement, this assumption ignores other potential fire risks within the fixture itself.

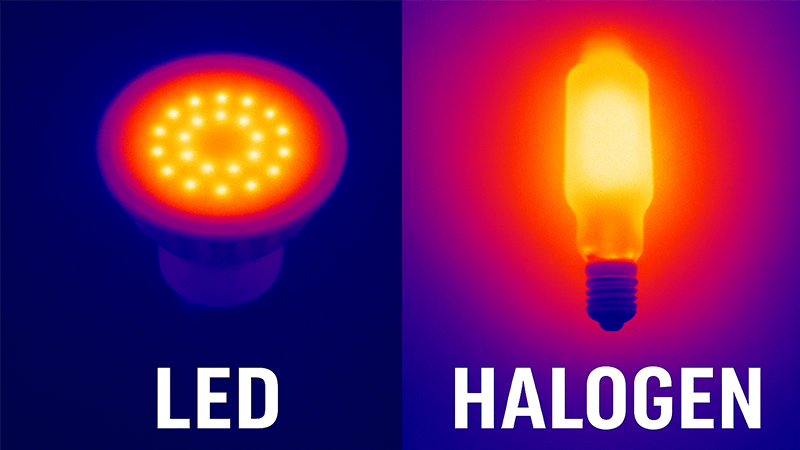

Yes, LED lights are generally less of a fire hazard12 than older halogen bulbs because they produce significantly less heat. However, the driver and internal electronics can still overheat and fail, potentially creating a fire risk if the product is poorly made or uses non-flame-retardant materials13.

In my factory, we have seen the evolution from halogen to LED firsthand. The reduction in heat was a game-changer for safety and energy efficiency. However, it also introduced a new point of potential failure: the driver, which converts AC power to the low-voltage DC that LEDs use. A common mistake is to focus only on the heat of the LED chip itself. But as a manufacturer, I know the real risk often lies in the components you can't see.

Heat Output: LED vs. Halogen

The primary reason LEDs are safer is their efficiency. Let's compare a typical 50W halogen downlight to a 7W COB LED downlight that produces a similar amount of light.

| Feature | 50W Halogen Downlight | 7W COB LED Downlight |

|---|---|---|

| Heat Emission | Radiates over 90% of its energy as heat. | Radiates less than 20% of its energy as heat. |

| Surface Temp. | Can reach over 200°C (392°F). | Typically operates between 60°C and 80°C (140-176°F). |

| Fire Risk | High risk. Can ignite combustible materials nearby. | Low risk from the light source itself. |

| Components | Simple bulb and holder. | LED chip, heat sink, driver, housing, lens. |

As you can see, the halogen bulb is a significant fire starter. I have heard stories of insulation smoldering in ceilings because it was too close to a halogen light. LEDs solve this problem almost completely. Their low operating temperature means they are extremely unlikely to ignite surrounding materials like wood joists or insulation. This is a massive leap forward in building safety.

The Hidden Danger: The Driver and Materials

However, the "cool" reputation of LEDs can create a false sense of security. An LED downlight isn't just the chip; it's a system. The most critical component is the driver. A poorly designed or cheaply made driver can easily overheat. If the internal components short-circuit or fail, temperatures can rise high enough to melt the driver's plastic casing. This is where the user's insight about 'fake' fire-rated products14 is so important. Some manufacturers cut costs by using non-flame-retardant ABS plastic for the driver housing or even for parts of the light fixture itself, like the decorative trim ring. If the driver overheats, this cheap plastic can catch fire and drip flaming material, spreading the fire. A truly safe LED downlight uses high-quality, flame-retardant materials (like polycarbonate with a V-0 rating) for all its components and has a driver with built-in thermal protection15 to shut down before it gets dangerously hot. For a buyer like Shaz, insisting on seeing the material specifications for both the light and the driver is a crucial step in avoiding these hidden dangers.

Do COB lights get hot?

You've heard COB LEDs are powerful, but that power must go somewhere. This makes people wonder if they generate enough heat to be a concern, just like the old halogens.

Yes, COB (Chip on Board) lights do get hot, but the heat is concentrated at the chip level and is managed by a heat sink. While the COB chip itself can get very hot, a well-designed fixture ensures the external housing remains at a safe temperature, well below fire risk levels.

From a manufacturing perspective, thermal management is one of the most critical aspects of designing a high-quality COB LED product. We pack a lot of light-emitting diodes into a very small area, which creates an intense, centralized heat source. The key to a safe and long-lasting product isn't just the COB chip itself, but the entire system built around it to draw that heat away.

Understanding COB Heat Generation

A COB LED16 works by mounting multiple LED chips directly onto a substrate to form a single module. This design allows for a much higher light density and intensity compared to standard SMD (Surface Mount Device) LEDs. However, all that concentrated energy produces a significant amount of heat in a very small area. The junction temperature (the temperature at the actual P-N junction of the diode) of a COB chip can easily exceed 100°C if not managed. This heat is the enemy of both performance and longevity. If it's not drawn away effectively, the light output will decrease, the color can shift, and the life of the chip will be drastically shortened. More critically for safety, this unmanaged heat can be transferred to other components of the luminaire, potentially creating a fire hazard.

The Critical Role of the Heat Sink

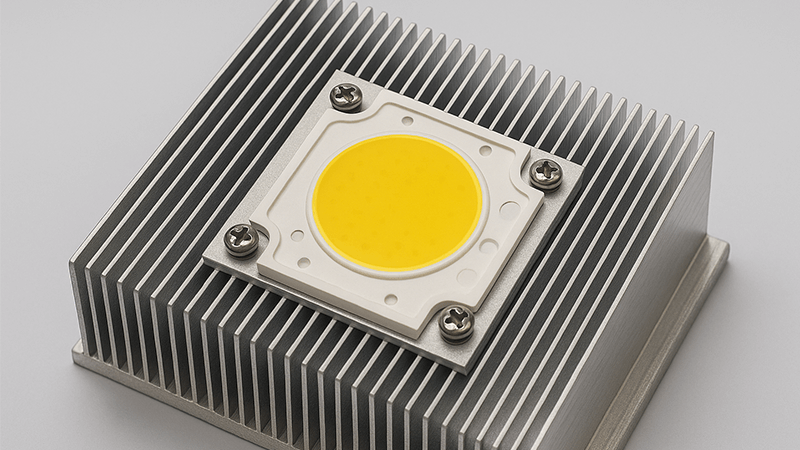

This is why the heat sink17 is arguably the most important part of a COB downlight's design. The heat sink is a piece of metal, usually aluminum, designed with a large surface area (often with fins) to dissipate heat into the surrounding air.

Here's how it works:

- Conduction: The COB chip is mounted directly onto the heat sink, often with a thermal paste in between to ensure a perfect connection. Heat flows rapidly from the small, hot chip into the large mass of the heat sink.

- Convection: As the heat sink gets warm, it heats the air around it. This warm air rises, and cooler air moves in to take its place, creating a continuous cooling airflow.

- Radiation: The heat sink also radiates thermal energy away from itself.

A well-designed heat sink keeps the COB chip at its optimal operating temperature and ensures the external, touchable parts of the downlight stay safe. When I'm evaluating a new design in my factory, the first thing I look at is the size and design of the heat sink relative to the wattage of the COB chip. A small, flimsy heat sink on a high-power COB is a major red flag for both poor performance and potential safety issues. A robust, well-engineered heat sink is a sign of a quality product built to last. For a professional buyer, asking for the Tc point (temperature test point) data is a good way to verify the effectiveness of the thermal management.

Conclusion

In short, choosing certified fire-rated COB LED downlights is a simple but powerful way to enhance building safety, maintain regulatory compliance, and protect both property and lives from fire.

Explore the concept of fire barriers and their role in building safety. ↩

Explore the advantages of fire-rated downlights for enhanced safety and compliance in building design. ↩

Understand the importance of maintaining fire resistance integrity for safety in construction. ↩

Learn how intumescent materials expand during a fire to block smoke and flames, crucial for safety. ↩

Learn about the role of emergency services in managing building fires and safety. ↩

Understand the implications of legal liability related to fire safety in construction. ↩

Explore essential regulations to ensure compliance and safety in lighting installations. ↩

Discover the significance of BS 476-21 in testing fire resistance of building materials. ↩

Learn about critical fire safety codes that govern building safety and compliance. ↩

Find out how the CE mark ensures products meet health and safety standards in Europe. ↩

Get insights into the UAE's fire safety regulations and their importance for compliance. ↩

Identify potential fire hazards in lighting to enhance safety in installations. ↩

Learn about the dangers of using non-flame-retardant materials in lighting fixtures. ↩

Get tips on identifying genuine fire-rated products for safety assurance. ↩

Understand the role of thermal protection in preventing overheating and fire hazards. ↩

Discover the benefits of COB LED technology for energy efficiency and safety. ↩

Learn about the critical role of heat sinks in managing temperature and ensuring safety. ↩