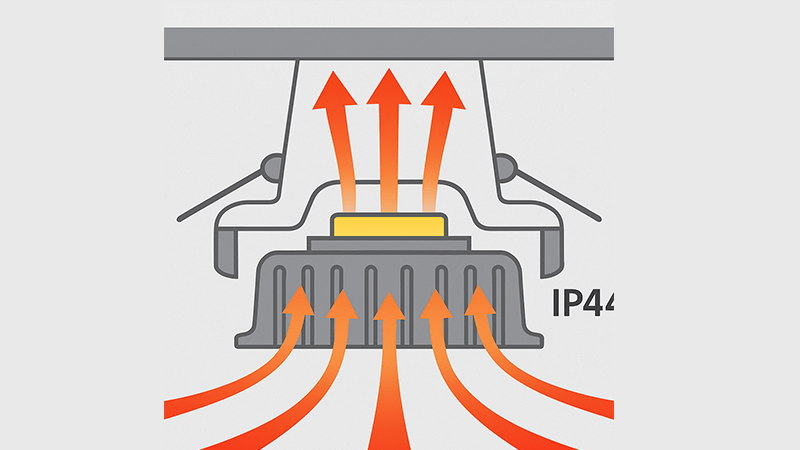

You invested in IP44 LED downlight1s, expecting years of service. But they fail too soon, hurting your project's timeline and your reputation. The hidden reason is often poor heat dissipation2.

Proper heat dissipation is crucial for the lifespan of an IP44 LED downlight. Excess heat degrades the LED chips and internal components, causing the light to dim or fail completely. A correctly sized heat sink ensures the light performs reliably for its entire rated life.

We all expect LED products to be a long-term investment. That longevity is a key part of the technology's promise. But to understand why some lights last and others burn out prematurely, we need to look closer at the engineering behind them. Many of my clients ask me fundamental questions about how these lights work, especially when it comes to heat. Understanding these basics is the first step toward protecting your investment and making smarter purchasing decisions. Let's break down some of the most common questions I hear.

Do LED downlights heat up?

You've been told that LEDs are cool and efficient, but you touch your new downlight and it feels warm. This contrast can be confusing and make you worry about safety or longevity.

Yes, LED downlights absolutely generate heat. While they are far more efficient than old halogen or incandescent bulbs, they don't convert 100% of electricity into light. The leftover energy becomes heat, which must be carefully managed by the light’s heat sink to prevent damage.

Let me explain this simply. An LED is a semiconductor. When electricity passes through it, it produces light. But this process isn't perfectly efficient. Some energy is lost as heat, right at the tiny LED chip. The temperature at this spot is called the "junction temperature." Keeping this temperature low is the single most important job of a downlight’s design. If the junction temperature3 gets too high, the LED becomes less efficient, its color can change, and its lifespan shortens dramatically. This is where the heat sink comes in. The heat sink is the metal body of the downlight, often with fins, designed to pull heat away from the LED chip and release it into the air.

The Mismatch Problem: A Common Factory Secret

In my years in lighting manufacturing, I’ve seen a dishonest trick that some factories use to offer a lower price. A customer, maybe a purchasing manager like you, asks for a 7W IP44 downlight. To win the order, a factory will use a heat sink that is only big enough for a 5W lamp. They build a 5W light but label and sell it as a 7W light. The price is very attractive. When you first turn it on, it looks bright enough. But the undersized heat sink can't handle the heat. The junction temperature skyrockets. Within months, the light fails. This is a classic example of how a cheap initial price becomes very expensive in the long run. The heat sink must match the power.

| Stated Wattage | Required Heat Sink | Heat Sink Used in Cost-Cutting | Result |

|---|---|---|---|

| 7W | Sized for 7W | Sized for 5W | Overheating, premature failure |

| 5W | Sized for 5W | Sized for 5W | Correct performance, long life |

Do LED downlights need to be changed by an electrician?

One of your LED downlights has stopped working, and you're thinking about how to replace it. Calling an electrician means extra cost and scheduling delays, so you wonder if it's a job you can do yourself.

Yes, for safety and in most legal jurisdictions, a qualified electrician must change a hard-wired LED downlight. These fixtures are connected directly to the mains electrical supply4. Improper installation is a serious fire and electrocution risk5. It's not a place to take chances.

Safety must always come first. The risk of working with mains electricity is just too high for someone who isn't trained. Most modern IP44 downlights used in bathrooms and other damp locations are "integrated" units. This means the LED light source, driver6, and housing are all one sealed piece. You can't just change a bulb. The entire fixture needs to be disconnected and replaced. An integrated design is better for waterproofing7 (the 'IP' rating) and for thermal management8, as the heat sink is part of the body. When one of these fails, the entire unit is swapped out.

The Driver is a Weak Link

Often, it's not the LED chip itself that fails first. It's the driver. The driver is the small electronic component that converts the high-voltage AC from your wall a to the low-voltage DC that the LED needs. Drivers are also very sensitive to heat. When a downlight with a cheap, undersized heat sink9 overheats, the driver gets "cooked" along with the LED. A poor-quality driver will fail quickly under thermal stress10, and the light will go dark. Replacing a driver is definitely a job for an electrician. This is another reason why choosing a downlight with a robust thermal design is so important. I had a client who bought a large batch of cheap downlights for an apartment project. Within a year, over 30% had failed. He had to pay for new, quality lights and also pay electricians a second time to replace all the bad ones. It was a costly lesson in the value of good engineering.

Do LEDs burn out over time?

You chose LEDs because you heard they last for tens of thousands of hours. But now you notice that your installed lights seem dimmer than they were when new, making you question their longevity.

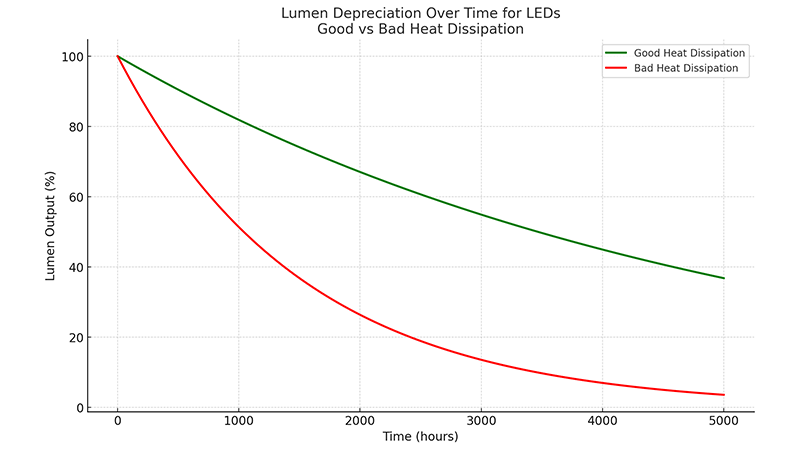

LEDs don't "burn out" and stop working suddenly like an old incandescent bulb. Instead, they experience a process called "lumen depreciation11." This means they gradually lose brightness12 over their long life. High heat is the main factor that accelerates this dimming process, causing them to fade much faster.

This gradual dimming is a natural part of how LEDs age. Reputable lighting manufacturers measure this and provide a rating called an L70 value. For example, an L70 rating of 50,000 hours means that after 50,000 hours of use, the light should still be producing at least 70% of its original brightness. This is considered the end of its useful life in many professional applications. However, this entire rating system depends on the LED operating at its designed temperature.

Heat: The Enemy of Brightness

Let's connect this directly back to our main topic of heat. The high temperatures caused by a poor heat sink permanently damage the phosphor coating13 on the LED chip. This phosphor is what converts the blue light from the diode into the white light we see. As the phosphor degrades, the light output drops and the color of the light can shift. This damage is irreversible.

Let's think about that dishonest 7W light with the 5W heat sink again. It's not just at risk of failing completely. Long before it dies, it will become noticeably dim. Its lumen depreciation will be terrible. While a properly designed 7W light might take 10 years to reach 70% brightness, the poorly cooled light could hit that same point in under a year. You thought you were buying a long-lasting product14, but because of poor thermal management, you received one that fades quickly.

| Feature | Properly Cooled 7W Light | Poorly Cooled 7W Light (5W Heatsink) |

|---|---|---|

| Initial Brightness | 100% | 100% (or temporarily higher) |

| Brightness after 1 year | ~95% | ~60% |

| Lifespan (to L70) | 50,000 hours | < 8,000 hours |

| Risk of Total Failure | Low | High |

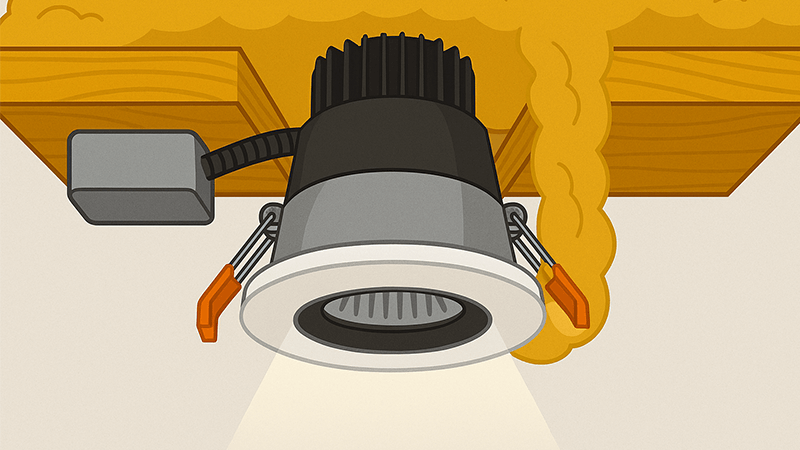

Can you put loft insulation over LED downlights?

You're adding insulation to your attic to improve your home's energy efficiency. But you have downlights installed in the ceiling below, and you're worried that covering them might be a fire hazard15.

You must not cover standard LED downlights with insulation. Trapping the light this way prevents its heat sink from working. The light will quickly overheat, leading to premature failure and creating a serious fire risk. Only "IC-rated" downlights can be safely covered.

This scenario is the ultimate test of a downlight's thermal management. Insulation is designed to trap heat, but a downlight is designed to get rid of heat. When you put them together, the insulation wins. The heat has nowhere to go, the components overheat, and the light fails. It’s like forcing someone to run a marathon while wearing a thick winter coat.

What is an IC-Rated Downlight?

An "IC-rated" or "Insulation Contact" rated downlight is one that has been specifically engineered and tested to be safely covered with insulation. These fixtures have superior thermal management systems. They are often built as a "can" or a sealed unit that allows heat to dissipate safely, even when fully enclosed. This prevents the fixture from reaching dangerous temperatures that could damage the light or, far worse, ignite the surrounding insulation or timber.

What to Do If Your Lights Aren't IC-Rated

If your existing downlights are not marked as IC-rated, you have a couple of options. First, you can buy and install loft caps or insulation guards. These are plastic or metal covers that fit over the back of the downlight, creating a protected air gap around it. You can then lay insulation over the guard, but not directly on the light. The better, safer, and more permanent solution is to replace the non-rated fixtures with new, certified IC-rated downlight16s. This brings us back to quality. Engineering a light to be IC-rated is not simple or cheap. It requires robust design and testing. If you see a product advertised as IC-rated at an unbelievably low price, you should be skeptical. Your supplier should always be able to provide the official certification documents17 to prove their product is safe for insulation contact.

Conclusion

Effective heat dissipation is the most critical factor for a long-lasting IP44 LED downlight. Always choose quality lights with proper thermal management to ensure performance and avoid costly early failures.

Explore the advantages of IP44 LED downlights for better lighting solutions in damp areas. ↩

Understanding heat dissipation can help you choose better LED downlights, ensuring longevity and performance. ↩

Understanding junction temperature is key to grasping how heat affects LED lifespan and efficiency. ↩

Gain insights into how LED downlights connect to mains supply for safe and effective operation. ↩

Learn about the serious risks involved in changing LED downlights and the importance of safety. ↩

Understanding the driver’s function can help you choose more reliable LED downlights. ↩

Learn about the importance of waterproofing in LED downlights for safety and durability. ↩

Explore the role of thermal management in ensuring the reliability and longevity of LED downlights. ↩

Learn how heat sinks improve LED performance and longevity, crucial for making informed purchases. ↩

Understanding thermal stress can help you choose downlights that last longer and perform better. ↩

Discover how lumen depreciation impacts LED brightness over time and what to expect from your lights. ↩

Explore the relationship between heat and brightness to ensure your LED lights perform optimally. ↩

Discover how phosphor coating affects LED light quality and longevity. ↩

Find out the key features that contribute to the longevity of LED downlights for better investments. ↩

Understanding fire hazards associated with LED downlights can help you make safer choices. ↩

Find out why IC-rated downlights are essential for safe insulation contact and fire prevention. ↩

Explore why certification documents are crucial for ensuring the safety and quality of LED products. ↩