Are you choosing between different downlight technologies? The wrong choice can lead to poor lighting and disappointed clients. I will help you understand the key differences to make the right decision.

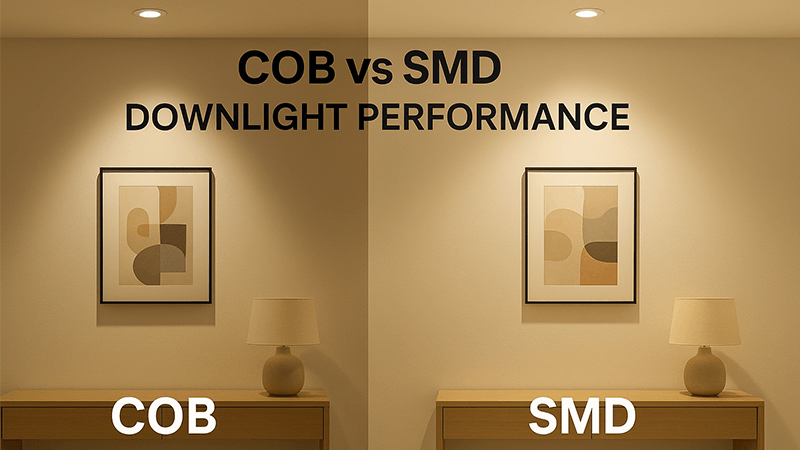

An IP44-rated downlight's performance depends on its light source. COB (Chip on Board) provides a focused, intense beam, like a spotlight. SMD (Surface Mounted Device) creates a broader, softer wash of light. The IP44 rating itself just means it's splash-proof, not related to the light source.

Choosing between COB and SMD technology is one of the most common questions I get from purchasing managers like you. It feels like a complex technical decision, but it's simpler than you think once you understand the core differences. Both technologies are excellent, but they are designed for very different jobs. Understanding which one to use for a specific application is the secret to creating perfect lighting environments1 every single time. Let's break down the details so you can choose with confidence for your next project.

Which is better, COB or SMD?

Feeling confused about choosing between COB and SMD? A wrong choice can mean uneven lighting or higher costs. Let's make it clear which technology is right for your project.

Neither technology is universally "better." COB (Chip on Board) is best for creating a single, powerful, focused beam of light. SMD (Surface Mounted Device) is ideal for wide, even, and diffuse illumination. The best choice depends entirely on your specific lighting goal.

Dive Deeper

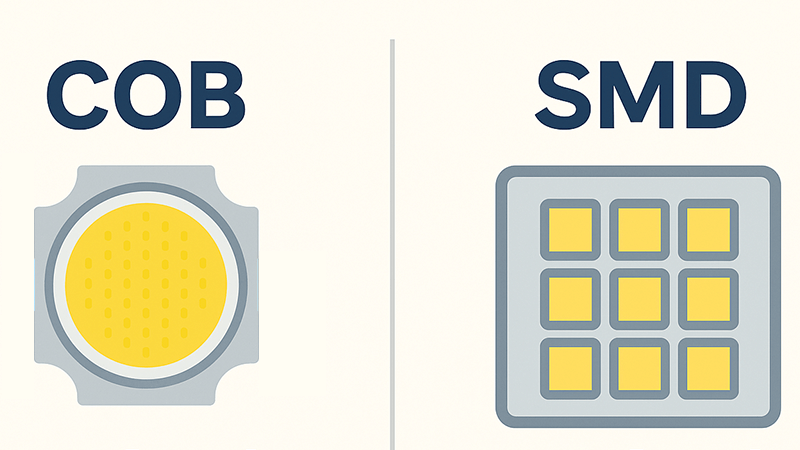

When I first started in this industry, the differences between COB and SMD seemed minor. But over the years, I've learned that using the right one is critical. Think of it this way: COB consolidates many small LED chips into one large, single module. When it lights up, it looks like one single, powerful light source. In contrast, SMD technology uses individual, larger LED chips2 soldered separately onto a circuit board. You can often see the individual points of light.

This structural difference directly impacts their performance. I remember a project for a hotel lobby in Dubai. The designer wanted a dramatic effect, with sharp pools of light on the marble floor from a high ceiling. We used COB downlights. The intense, focused beam3s created exactly the high-contrast look4 they wanted. For the guest hallways, we switched to SMD downlights. Their wide beam angle provided smooth, even light with no dark spots, making the space feel safe and welcoming. Using the wrong light in either space would have ruined the design.

Here’s a simple table to help you decide:

| Feature | COB (Chip on Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Light Appearance | Single, uniform light source | Multiple, distinct points of light |

| Light Quality | Intense, focused, high-contrast | Wide, diffuse, even illumination |

| Best For | Spotlights, high ceilings, accent lighting | General lighting, large areas, ambient light5 |

| Heat Dissipation | Concentrated heat, needs a superior heat sink | Heat is spread out, less demanding on heat sink6 |

| Cost | Can be slightly higher due to thermal needs | Often more cost-effective for general lighting7 |

The key takeaway is to match the technology to the task. For drama and focus, choose COB. For broad, comfortable lighting, choose SMD.

Are COB lights more efficient?

Worried about high energy bills for your project? Choosing a less efficient light source can increase long-term operational costs. Let's see if COB technology really saves more energy.

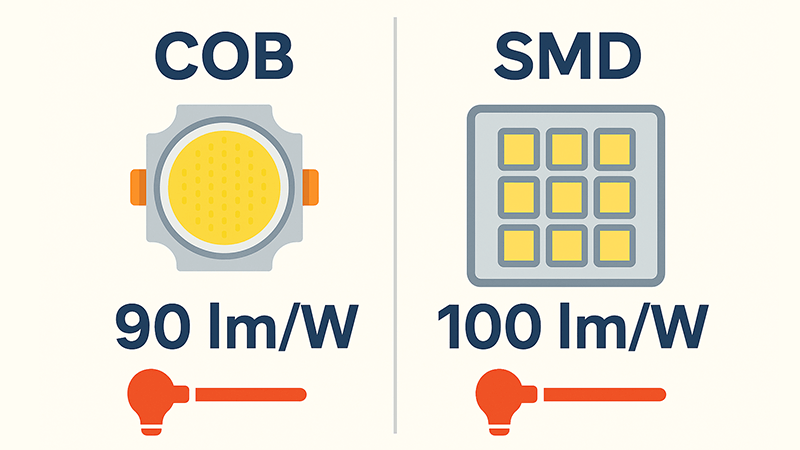

Yes, generally, COB LEDs are more efficient in lumens per watt. Their design packs more light-emitting sources into a smaller area and allows for a more direct thermal path, resulting in more light output8 for the same amount of power compared to many standard SMD packages.

Dive Deeper

Efficiency in lighting is measured in lumens per watt (lm/W). It’s simple: how much light (lumens) do you get for each unit of energy (watt) you put in? A higher number means better efficiency and lower electricity bills. COB technology often wins in this area because of its design. The LED chips are mounted directly onto a substrate, which creates a very short and efficient path for heat to escape. And managing heat is everything when it comes to efficiency.

A while ago, a client, Shaz, a purchasing manager from the UAE, was sourcing for a large residential tower. His main concern was the long-term running cost. We looked at two 10-watt downlights, one with a COB chip and one with SMD chips. The COB model produced around 1100 lumens, while the SMD was closer to 950 lumens. That's over 15% more light for the same energy cost. When you multiply that saving across thousands of apartments, the financial impact is huge.

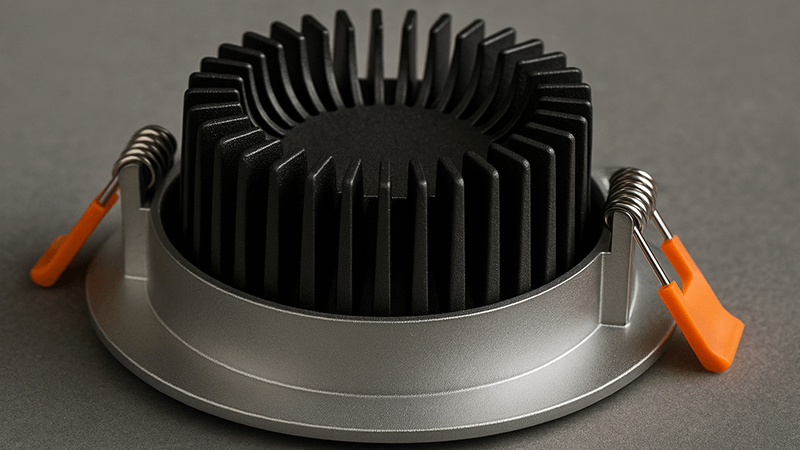

However, this efficiency comes with a condition: you must manage the heat. Because the chips are so densely packed, COB lights produce a lot of focused heat. This heat must be drawn away quickly. I always explain that the LED chip is the engine, but the heat sink is the radiator. You can’t have a powerful engine with a tiny radiator. For our COB products, we insist on using high-quality, heavy aluminum heat sinks. We also use a 3.0 standard thermal grease. This special paste fills microscopic air gaps between the chip and the heat sink, ensuring heat transfers away lightning-fast. Skimping on this and using a cheaper 2.0 standard grease would cause the chip to overheat, killing its efficiency and lifespan.

What is brighter, LED or COB?

Need the most powerful light for your space? Picking the wrong type can leave a room looking dim and uninviting. Let's clarify which technology delivers the brightest light.

This question is slightly confusing, as COB is a type of LED. The better comparison is between COB and SMD LEDs. COB technology can pack more light sources into a smaller area, creating a much brighter and more intense beam from a single point compared to individual SMD chips.

Dive Deeper

Let’s clear up a common point of confusion first. LED (Light Emitting Diode) is the core technology. COB (Chip on Board)9 and SMD (Surface Mounted Device)10 are just two different ways to package and implement that technology. So, the real question is, "Which packaging method, COB or SMD, creates a brighter light?" The answer depends on what you mean by "brighter."

Do you mean total light output (lumens), or do you mean focused intensity (candela)?

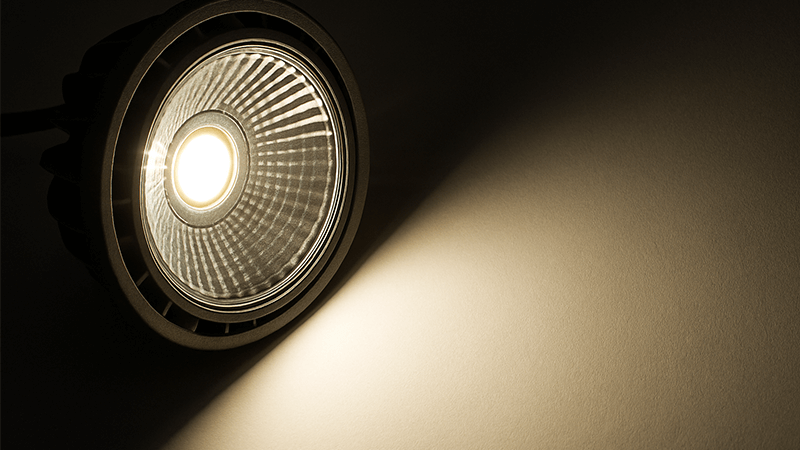

- Intensity (Candela): This is where COB excels. Because all the LED chips are concentrated in a small area, it acts like a single, massive light source. This creates a very intense, focused beam of light, much like a traditional halogen spotlight. If you want to create a "punch" of light that travels a long distance or makes an object sparkle, COB is almost always the brighter choice in terms of perceived intensity.

- Total Output (Lumens): An SMD fixture can technically have a higher total lumen output if it uses enough chips spread over a large enough surface area. However, that light will be very diffuse and spread out over a wide angle. It will illuminate a room evenly but won't have that sharp, focused punch.

I once worked on a lighting plan for a high-end jewelry store. The client’s goal was simple: make the diamonds sparkle. We first tried SMD downlights. They made the room bright, but the diamonds looked flat. We then switched to narrow-beam COB spotlights11 aimed at the display cases. The difference was incredible. The intense, single-point light source from the COB chips created that fire and brilliance in the gems. The perceived brightness on the jewelry was ten times higher, making the products look far more valuable.

Think of it like this: an SMD light panel is like a floodlight, illuminating a wide area. A COB light is like a laser beam, putting all its energy into one spot.

What is the lifespan of a COB LED?

Are you tired of replacing failed lights? A short lifespan means more maintenance costs, more hassle, and unhappy clients. Let's look at how long a quality COB LED should last.

A well-engineered COB LED, supported by excellent thermal management12, will typically last between 30,000 and 50,000 hours. The single most important factor determining this lifespan is the quality of the heat sink and its connection to the LED chip.

Dive Deeper

The lifespan of an LED isn't like a traditional bulb that suddenly "burns out." Instead, its light output slowly fades over time. The industry standard for lifespan, known as L70, is the point at which the LED produces only 70% of its original brightness. So, a 50,000-hour rating means it will maintain at least 70% of its light for that long.

The number one enemy of any LED, and especially a COB LED, is heat. All the energy that doesn't become light becomes heat, and in a COB, that heat is generated in a very small, concentrated area. If that heat isn't removed effectively, it will rapidly degrade the LED chips, causing the light output to drop and the color to shift. This is where my insights from years of manufacturing become so important. The quality of the heat sink is not optional; it's essential.

For our COB downlights, we use heavy, die-cast aluminum heat sinks with a large surface area. But the heat sink6 alone isn't enough. The heat must get from the chip to the heat sink. I always tell my team, "The thermal path is only as strong as its weakest link." That weak link is often the thermal interface material13. We use a high-conductivity 3.0 standard thermal grease. This paste ensures a perfect, gap-free connection so heat can transfer instantly. Using a cheaper, lower-grade 2.0 standard grease on a COB light is a recipe for failure. It creates a thermal bottleneck that cooks the chip from the inside out, potentially cutting its lifespan in half.

For SMD downlights, the heat is more spread out, so the requirements are slightly less extreme. But quality still matters. We still use a solid heat sink and at least a 2.0 standard grease to ensure they reach their full potential lifespan.

Factors that determine the real-world lifespan:

| Factor | Impact on COB Lifespan |

|---|---|

| Heat Sink Quality | Critical. A poor heat sink will cause rapid failure. Must be oversized. |

| Thermal Grease | Critical. High-grade (3.0+) grease is necessary for proper heat transfer. |

| Driver Quality | High. A poor-quality driver will fail long before the LED chip. |

| Operating Environment | High. High ambient temperatures reduce lifespan and efficiency. |

Never trust a lifespan claim without checking the quality of the thermal management components. It is the core of a reliable lighting product.

Conclusion

Ultimately, choosing between COB and SMD depends on your goal. COB delivers powerful, focused light for accents and drama. SMD provides wide, even light for general illumination. Both can last for years with proper thermal management.

Explore strategies for designing effective and appealing lighting environments. ↩

Gain insights into the technology behind LED chips for better lighting choices. ↩

Discover how focused beams can enhance the aesthetics and functionality of your lighting design. ↩

Explore techniques to create dramatic lighting effects in your projects. ↩

Learn how ambient light can enhance the overall feel of a space. ↩

Understanding heat sinks can help you select reliable and efficient LED products. ↩

Explore the significance of general lighting in creating functional spaces. ↩

Discover the key factors that influence the brightness and efficiency of LED lights. ↩

Explore the benefits of COB technology for focused and intense lighting solutions. ↩

Learn how SMD technology can provide broad and even illumination for various spaces. ↩

Learn how to effectively use spotlights to highlight features in your space. ↩

Understanding thermal management can help you choose longer-lasting and efficient lighting solutions. ↩

Learn about the critical role of thermal interface materials in LED performance. ↩