Worried about inconsistent colors and early failures in your LED downlight imports? These hidden issues can damage your reputation. I'll show you how to spot them before you buy.

To avoid mistakes when importing LED downlights, you must look beyond the price. Focus on technical details like color consistency (SDCM), low light decay, the driver's quality, and effective anti-glare design. Don't fall for marketing claims, as quality is in the engineering.

As the founder of a lighting company, I've talked to hundreds of buyers. Many of them, like Shaz, a purchasing manager from the UAE, have learned tough lessons. They focused on the initial price and got products that failed quickly. The real value is in the details that many suppliers don't want to talk about. These are the secrets I learned over many years in the factory. You don't have to learn them the hard way. I will break down the most common problems and show you exactly what to look for. Let's dive into the key questions you should be asking.

How do you find a supplier who makes the best LED downlights?

Choosing a supplier feels like a huge risk. A bad choice means quality issues and project delays1. A great supplier acts as a true partner, invested in your project's success.

The best suppliers offer more than just a product. They provide transparency, solid engineering, and custom solutions. Look for manufacturers with deep industry experience, strict quality control processes, and OEM/ODM services to meet your specific project needs, like we do at Upward Lighting.

Finding the "best" supplier is not about finding the cheapest price. It’s about finding a partner who guarantees quality and understands your goals. After working my way up from the factory floor, I built my company, Upward Lighting, on principles that directly address where other suppliers fail. A great supplier should be transparent about their components and processes. This is how you can judge their quality.

What to Look for in a Top-Tier Supplier?

First, ask about their experience and their main markets. A supplier with a history of serving demanding markets likely has better quality control. Next, ask for detailed specifications, not just marketing brochures. A good supplier can immediately provide data on their drivers, LED chip2s, and materials. We pride ourselves on this transparency. We want you to know exactly what you're buying.

Finally, a top supplier should be a problem-solver. Can they customize a product for your project? Can they offer different anti-glare design3s or specific color temperatures4? This ability to provide OEM/ODM solutions shows they have real engineering depth5. It proves they are a manufacturer, not just a trader.

| Supplier Quality | Poor Supplier | Good Supplier (like Upward Lighting) |

|---|---|---|

| Transparency | Hides component brands and data | Provides full technical data sheets |

| Customization | Offers only standard products | Provides flexible OEM/ODM solutions |

| Communication | Slow replies, vague answers | Clear, prompt, and technical replies |

| Focus | Lowest price | Best value and long-term reliability |

What is the common problem with LED lights?

You source new LED lights that look great at first. But soon, your clients complain about flickering, inconsistent colors, and some lights failing completely, damaging your credibility.

The most common hidden problem is poor color consistency, measured by SDCM. Many low-quality lights have a high SDCM value6, causing visible color differences between fixtures. Other issues are rapid light decay, where brightness fades quickly, and using low-quality drivers that cause flicker.

Many importers focus on lumens per watt and price. They think high efficiency means a good light. But I’ve learned that some of the most important issues are the ones you can't see on a standard spec sheet. These are the problems that show up a few months after installation.

The Problem of Color Consistency (SDCM)

Color consistency is critical for professional projects. It is measured in "Standard Deviation of Color Matching," or SDCM. A low SDCM value means the light color is very consistent from one lamp to the next.

- SDCM < 3: The color difference is invisible to the human eye. This is the standard for high-end projects.

- SDCM < 5: A slight difference might be noticeable if you look closely. This is acceptable for many commercial uses.

- SDCM > 5: The color difference is obvious. A bad supplier might ship lights with an SDCM of 7 or more.

Bad suppliers never mention the SDCM value. They buy the cheapest LED chips available, and the color varies wildly. When you install 20 of their downlights in a room, some will look warm white, and others will look cool white. It makes the entire project look cheap. Always ask for the SDCM value before you place an order.

High Efficiency vs. Fast Light Decay

Another trick is to promote a very high "luminous efficacy7," or lumens per watt. The light seems incredibly bright when you first test it. The problem is, to achieve this cheaply, manufacturers overdrive the LED chips. They push too much current through them. This makes the chips very hot, causing them to degrade quickly. The light might lose 30% of its brightness in just six months. A quality light is designed for longevity, not just initial brightness. It will have a proper heat sink and be driven at a safe current to ensure it maintains its brightness for years.

Why do LED downlights fail?

You invest in a large shipment of LED downlights for a big project. But within a year, you get calls about failures, forcing you to spend time and money on replacements.

LED downlights usually fail for two main reasons: the driver or the LED chip. The driver, which converts AC power to DC, is often the first part to break due to low-quality components. The LED chip can fail from overheating caused by poor heat sink design.

In my experience, the light source itself—the LED chip—is rarely the first thing to break in a quality product. Reputable brands like Cree, Bridgelux, or Philips make chips that last a very long time. The failure almost always comes from the supporting components around the chip. A lighting fixture is a system, and it is only as strong as its weakest link.

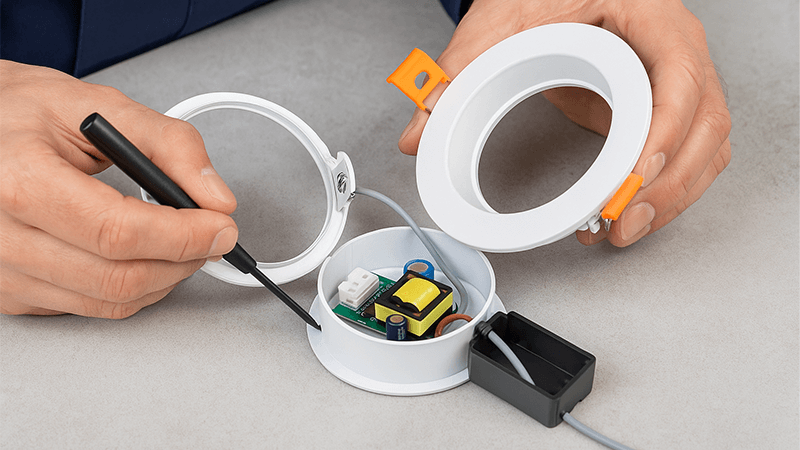

The Driver: The Heart of the Downlight

The driver is the most common point of failure. It's a small power supply that converts the high-voltage AC from the wall into the low-voltage DC that the LED needs. Cheap drivers are made with low-quality capacitors and other electronic components that cannot handle heat or power fluctuations. After a few months of use, they simply burn out. When the driver fails, the light goes dead, even though the LED chip is still perfectly fine. A good supplier will use drivers from reputable brands and be able to tell you exactly what brand they use.

Heat: The Silent Killer of LEDs

The second biggest cause of failure is heat. LED chips produce heat, and it must be moved away from the chip efficiently. This is the job of the heat sink, which is usually the aluminum body of the downlight.

- Poor Design: A cheap downlight may have a thin, poorly designed heat sink made from low-grade aluminum. It cannot dissipate the heat effectively.

- Overheating: The LED chip gets too hot, which causes its brightness to permanently decrease (light decay) and can lead to complete failure.

When I design a new downlight, my first focus is on thermal management8. A good heat sink adds cost and weight, but it's the only way to guarantee a long life for the product. Before you buy, look at the physical construction of the downlight. Does it feel solid? Does it have deep fins to help dissipate heat? These are signs of a well-engineered product.

How many years do LED downlights last?

You need to assure your client that the lights you install will last for years. But different suppliers give you wildly different lifetime ratings, leaving you unsure of what to promise.

A quality LED downlight should last between 30,000 and 50,000 hours. If used for 8 hours a day, this translates to 10 to 17 years. However, this depends entirely on the quality of the driver and the effectiveness of the heat sink design.

The "50,000-hour" lifetime you see everywhere is not a guarantee. It is a calculated estimate based on testing the LED chip under ideal lab conditions. The real-world lifespan9 of the entire fixture depends on the quality of every single component working together. A 50,000-hour LED chip powered by a 5,000-hour driver will only last 5,000 hours. This is a critical detail many importers miss.

Understanding L70 Lifetime

The lifetime is usually rated as "L70." This means the time it takes for the light to lose 30% of its initial brightness. So, an L70 of 50,000 hours means that after 50,000 hours of use, the light will still produce at least 70% of its original light output. It doesn't mean the light will be dead. However, a cheap light can have a very poor L70 lifetime, dimming very quickly.

Key Factors That Determine Real-World Lifespan

When I evaluate a product's lifespan, I ignore the marketing claims and look at the engineering.

- Driver Brand and Warranty: Is the driver from a trusted brand? What is the warranty on the driver10 itself? A 5-year warranty on the driver is a good sign.

- Heat Sink Construction: Is it made of die-cast or extruded aluminum? Does it have a large surface area? A heavy, well-built heat sink means better heat management and a longer life.

- Operating Environment: The lifetime rating is based on an ambient temperature11 of around 25°C (77°F). If you install a downlight in a hot ceiling with no ventilation, its lifespan will be much shorter.

You should always be skeptical of huge lifetime claims from a low-cost supplier. True longevity comes from quality engineering and good materials, and those things cost money. It's better to have an honest 30,000-hour rating on a quality product than a fake 50,000-hour rating on a cheap one.

Conclusion

To successfully import LED downlights, you must prioritize engineering over marketing. Focus on SDCM for color, quality drivers and heat sinks for lifespan, and a reliable, transparent manufacturing partner.

Learn strategies to prevent project delays, ensuring timely delivery and installation of LED lights. ↩

Understanding the LED chip's role helps you choose reliable lighting solutions for your projects. ↩

Discover the importance of anti-glare design for comfortable lighting in various environments. ↩

Understanding color temperatures helps you select the right lighting for various applications. ↩

Learn about engineering depth to ensure you partner with manufacturers who prioritize quality. ↩

Knowing how to assess SDCM value ensures you choose high-quality LED lights with consistent color. ↩

Learn about luminous efficacy to understand how brightness and efficiency are measured in LEDs. ↩

Learn about thermal management to ensure your LED lights operate efficiently and last longer. ↩

Understanding lifespan factors helps you choose durable LED products for your lighting needs. ↩

Understanding warranty details helps you assess the reliability of LED drivers in your projects. ↩

Learn how ambient temperature impacts LED lifespan to make informed installation decisions. ↩