Having trouble picking the right wattage? The wrong choice can mean dim spaces and wasted energy. Here’s how to nail it every time.

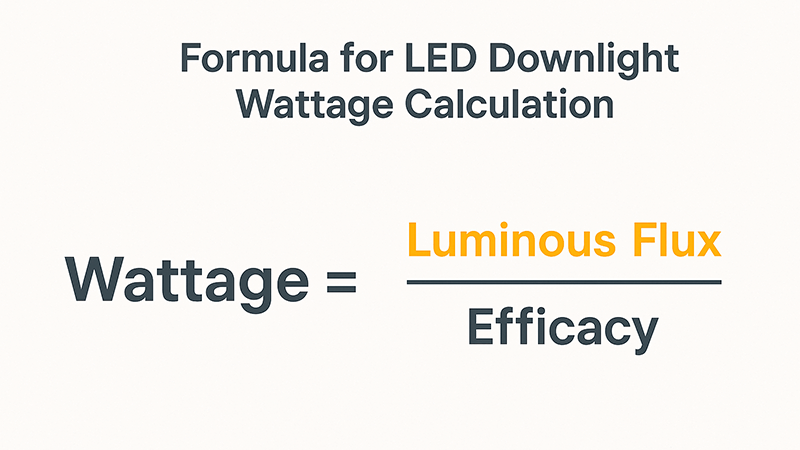

To calculate the LED downlight wattage, first determine the lumens needed for your space (Area in sq ft x Footcandles). Then, divide the total lumens by the downlight's system efficacy (lumens per watt). This gives you the total wattage required for the area.

That's the basic formula. But as a professional with ten years in this industry, you know the real world is more complex. The factors that truly matter go far beyond simple math. Let's break down what experienced purchasing managers need to look for to ensure quality and performance, not just a number on a spec sheet.

How do I calculate how many LED downlights I need?

Worried about creating dark spots1 or overpowering a room with too many lights? Miscalculating the number of downlights needed is a common and costly project mistake. Here’s how you can avoid it.

First, calculate the total lumens your space requires (Room Area x Required Footcandles). Then, divide this total lumen figure by the lumen output of a single downlight. This will give you the number of fixtures needed for proper illumination.

Dive Deeper

The number of lights you need is not just about lumen output2. It is really about how that light is delivered. This is where we move beyond simple calculations and into professional lighting design3. I've learned that focusing on application-specific needs, rather than just raw numbers, makes all the difference. Factors like beam angle4 and glare control5 are what separate an average installation from an exceptional one.

The Role of Beam Angle and Spacing

Your choice of beam angle directly impacts how many lights you will need. A narrow beam creates a focused, intense pool of light, which is great for accenting features. But for general lighting, it would require more fixtures spaced closer together to avoid dark patches. A wide beam spreads light more evenly, allowing you to use fewer fixtures with wider spacing.

Here’s a practical table I use:

| Application | Recommended Beam Angle | Spacing Implication |

|---|---|---|

| Task Lighting (e.g., Kitchen Counter) | 15°-25° (Narrow) | Fixtures must be close together directly over the task area. |

| General Lighting (e.g., Office) | 38°-60° (Medium/Wide) | Wider spacing is possible, creating uniform ambient light. |

| Accent Lighting (e.g., Art Gallery) | <15° (Very Narrow) | Lighting is targeted; general coverage is not the goal. |

Moving to Application-Specific Lumen Density

This brings me to a concept I push with all my partners: "Application-Specific Lumen Density6." Forget old ideas like wattage equivalence7. The real question is not "what is the LED version of a 50W halogen?" The right question is "what quality and quantity of light does this specific space need to function well?" For an office, you need high uniformity and low glare8 (UGR < 19). For a retail store, you need high color rendering to make products look appealing. Each application demands a different approach to lumens9, beam angle, and quality, which ultimately determines the number of fixtures.

How to calculate LED light wattage?

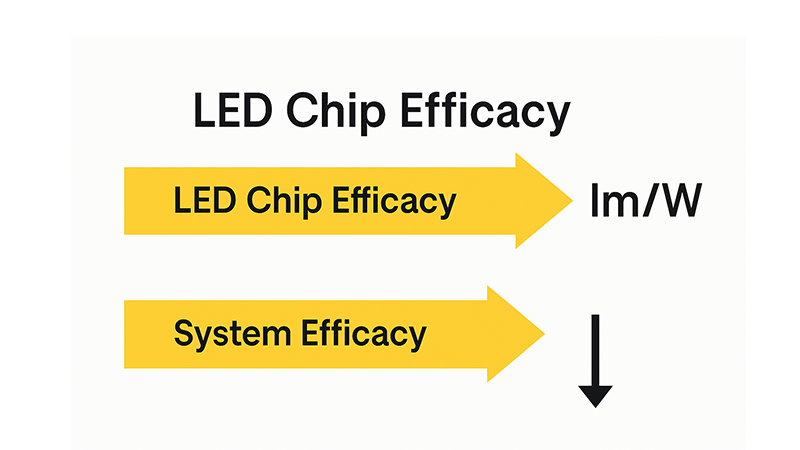

Are misleading spec sheets causing you problems? Many suppliers highlight "chip efficacy10" but the real-world performance is much lower. This can seriously impact your project's energy and lighting goals.

To truly calculate wattage, you must use system efficacy, not chip efficacy. Divide the required lumen output for the fixture by its system efficacy (lumens per watt). For example, a 1000 lumen downlight with a system efficacy of 100 lm/W requires 10 watts.

Dive Deeper

One of the biggest lessons I’ve learned in manufacturing is the difference between data on a page and performance in the field. When I first started, I was also impressed by the high efficacy numbers on LED chip specification sheets. But I quickly realized that the number that truly matters to you, the buyer, is the "system efficacy."

The Deception of "Chip Efficacy"

A raw LED chip, tested in a perfect lab environment, might reach 220 lumens per watt (lm/W). Suppliers love to advertise this number. But that chip doesn't work in isolation. It gets installed into a fixture with other components, and each one causes a loss in efficiency.

- The Driver: The power supply that runs the LED is not 100% efficient. It consumes power and creates heat, typically causing a 10-15% loss.

- Thermal Management: LEDs generate heat. The heatsink assembly, while necessary, means the LED runs at a higher temperature than in the lab. This heat reduces its efficiency.

- Optics: Lenses and diffusers are used to shape the light and reduce glare. However, every layer of material the light passes through absorbs a small amount, leading to another 5-15% loss.

Why "System Efficacy" is the Only Metric That Matters

System efficacy is the final lumen output of the entire fixture divided by the total watts it consumes from the wall. This is the real-world performance figure. A downlight using a 220 lm/W chip might only deliver a system efficacy11 of 100-130 lm/W after all these losses.

Here is a breakdown of what happens:

| Component Factor | Typical Efficiency Loss | Impact on an Initial 2200 Lumens (from a 10W chip) |

|---|---|---|

| Raw Chip Output | 0% (Baseline) | 2200 Lumens |

| Driver Loss | ~12% | -264 Lumens |

| Optical Loss | ~10% | -220 Lumens |

| Thermal Loss | ~5% | -110 Lumens |

| Final System Output | ~27% Total Loss | ~1606 Lumens (System Efficacy: 139 lm/W, not 220 lm/W) |

As a purchasing manager, you must demand the system efficacy data. Any reliable manufacturer will provide a photometric report12 (like an IES file) that confirms this value. Don't be fooled by inflated chip specs; what matters is the light delivered to the room.

What watt LED downlight do I need?

Choosing the right wattage feels like guesswork. You need to balance brightness, comfort, and energy use. A light that is too bright causes glare, while one that is too dim fails its purpose.

Instead of focusing on watts, focus on the required lumens and color quality for your application. A high-quality 8W downlight can be better than a poor-quality 12W one. Prioritize system efficacy and CRI/R9 value13s for the best results.

Dive Deeper

When clients ask me what wattage they need, my first response is to shift the conversation away from watts and toward something much more important: light quality. The wattage is just an indicator of energy consumption. The real value is in the light the fixture produces. Specifically, I guide them to look closely at the Color Rendering Index (CRI)14 and, even more critically, the R9 value.

Why CRI Alone is Not Enough

For years, CRI has been the standard for measuring how accurately a light source renders color compared to natural daylight. A CRI of 80 is considered acceptable for general use, and 90+ is great. However, CRI is an average of only eight pastel colors (R1-R8). It completely ignores how a light renders strong, saturated colors, especially red.

This is where the R9 value comes in. R9 specifically measures how accurately a light reproduces saturated red. Why is this so important? Because so many things in our daily environment rely on rich red tones. Think of fresh produce in a supermarket, wood tones in furniture, or even skin tones. A light with a low R9 value will make these objects appear dull, flat, and unappealing, even if it has a high overall CRI.

The "R9" Value Imperative

A light source can have a CRI of 90 but an R9 value of less than 20. In this case, everything will look good except for things with red in them. In my experience, for any application where appearance matters – retail, hospitality, residential, and even healthcare – a high R9 value is non-negotiable.

Let’s visualize the impact:

| Metric | Low-Quality LED | High-Quality iPHD LED | Impact on Environment |

|---|---|---|---|

| CRI | 82 | 95 | Overall colors are reasonably accurate in both. |

| R9 | 15 | >80 | Red apples look brownish; wood grains look flat. |

| Result | A steak looks unappetizing. A red dress looks faded. | A steak looks juicy and red. A red dress is vibrant. |

When you select a downlight, don't just ask for the wattage. Ask for the photometric report and check the R9 value. I tell my partners that an R9 of 50 or higher is good, but for premium applications, you should look for an R9 of 80+. An 8W downlight with a high R9 is far superior to a 12W downlight that makes a space feel lifeless.

Is 100W LED brighter than 60W LED?

You assume a higher wattage always means a brighter light. But this is a common misunderstanding left over from the days of incandescent bulbs. In the world of LEDs, this is often not true.

Not necessarily. Brightness is measured in lumens, not watts. A high-efficiency 60W LED from a quality brand can produce more lumens (be brighter) than a low-efficiency 100W LED from a cheap manufacturer. Always compare lumens, not watts.

Dive Deeper

This question takes me back to the early days of LED adoption. We constantly had to re-educate customers who were used to buying incandescent bulbs, where watts directly equaled brightness. With LEDs, watts only tell you how much energy is being consumed. The real measure of brightness is lumens.

The idea that a 100W light is brighter than a 60W one is what I call the "obsolescence of wattage equivalence7." This thinking is outdated and can lead to poor purchasing decisions. The key factor is efficacy (lumens per watt).

The Problem with Wattage Comparison

Let's look at a real-world example. You are presented with two LED high bay lights for a warehouse project:

- Supplier A: Offers a 100W LED High Bay.

- Supplier B (iPHD): Offers a 60W LED High Bay.

Your first instinct might be to assume the 100W fixture is the more powerful, brighter option. But let's look at the actual performance data, specifically the system efficacy.

- Supplier A (Low Quality): Their 100W fixture has a low system efficacy of 80 lm/W.

- Total Lumens: 100W x 80 lm/W = 8,000 lumens.

- Supplier B (High Quality): Our 60W fixture has a high system efficacy of 150 lm/W.

- Total Lumens: 60W x 150 lm/W = 9,000 lumens.

Here is the truth:

| Fixture | Wattage | System Efficacy | Total Lumens (Brightness) | Energy Cost (10 hrs/day @ $0.15/kWh) |

|---|---|---|---|---|

| Supplier A | 100W | 80 lm/W | 8,000 lm | $547.50 / year |

| Supplier B (iPHD) | 60W | 150 lm/W | 9,000 lm | $328.50 / year |

In this scenario, the 60W LED is actually 12.5% brighter than the 100W LED, and it consumes 40% less energy. This is why, as a purchasing professional, you must train yourself and your team to ignore wattage as a primary indicator of performance. Always demand the lumen output and the system efficacy. This protects your project from underperforming products and saves your client significant money in the long run.

Conclusion

Calculating the right LED wattage isn't about watts at all. It's about understanding lumens, system efficacy, color quality (R9), and the specific application to ensure optimal performance and value.

Avoiding dark spots is essential for effective illumination; learn strategies to achieve uniform lighting. ↩

Knowing how to determine lumen output ensures you select the right brightness for your space. ↩

Mastering lighting design principles leads to better aesthetics and functionality in any space. ↩

Beam angle influences light distribution; knowing this can enhance your lighting design for specific applications. ↩

Effective glare control improves comfort and visibility, making it essential for quality lighting design. ↩

This concept helps tailor lighting solutions to specific needs, enhancing functionality and aesthetics. ↩

Understanding wattage equivalence helps avoid common misconceptions in lighting choices. ↩

Low glare lighting enhances comfort and productivity, making it essential for various environments. ↩

Lumens are crucial for determining brightness; knowing their impact helps in making informed lighting decisions. ↩

Understanding this difference helps avoid misleading specifications and ensures better lighting choices. ↩

System efficacy is key to understanding real-world performance of LED fixtures, ensuring you get the best value. ↩

A photometric report provides essential data on lighting performance, ensuring informed purchasing decisions. ↩

R9 value measures red color accuracy, crucial for applications where color appearance matters. ↩

CRI measures color accuracy; understanding it helps in selecting lights that enhance visual appeal. ↩