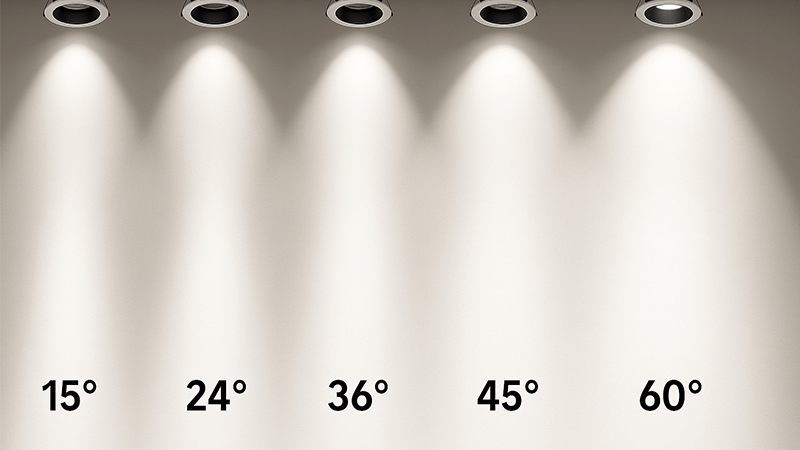

Choosing the wrong beam angle1 can kill a project. You get uneven light, glare, and unhappy clients. Let’s make sure you select the perfect beam angle every time.

The best beam angle depends on your ceiling height and lighting goal. For high ceilings or highlighting objects, use a narrow beam (10°-25°). For general room lighting, a wider beam (36°-60°) works best. Always match the angle to the specific task and space.

Getting this right seems simple, but there's more to it than just a number on a spec sheet. I've seen many projects succeed or fail based on this single choice. As a purchasing manager, you know that the details determine the quality and value of the final installation. This knowledge will not only help you source better products but also position you as an expert to your clients. We'll look at the technical details, spacing rules2, and how new technology can make your job easier. This information is key to making better purchasing decisions.

What exactly is the beam angle on LED lights?

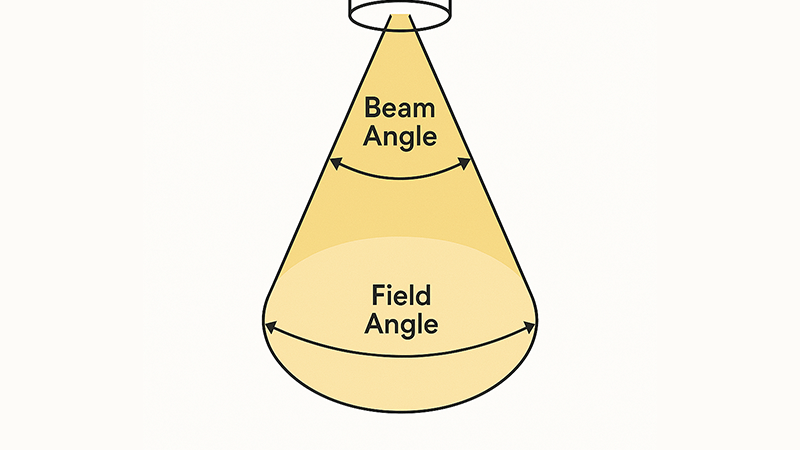

Every spec sheet lists a beam angle, but do you know what it truly means? Confusing it with field angle can lead to poor lighting outcomes and dissatisfied clients.

Beam angle is the angle where light intensity drops to 50% of its center maximum. The wider field angle includes the dimmer, spill light, down to 10% intensity. Focusing on just the beam angle ensures precise, quality illumination without unwanted light spill.

When you source lighting, the difference between beam angle and field angle is a critical detail that defines quality. Many manufacturers only list the beam angle, but the real performance is revealed when you compare it to the field angle. I remember a project a few years ago where a client sourced downlights advertised with a 36° beam. But in reality, the light produced hazy, undefined pools on the floor. When we measured it, the field angle was almost 80°. All that extra "spill light3" made the entire installation look sloppy and cheap. That experience taught me to always demand full photometric data4 from a supplier. A high-quality downlight has a beam angle that is very close to its field angle. This creates a clean, controlled beam with sharp edges and minimal glare. It’s a mark of superior optical engineering5.

Beam Angle vs. Field Angle: A Practical Guide

As a purchasing manager, asking a potential supplier about this distinction can quickly tell you about their product quality. A cheap reflector or lens will scatter light everywhere, resulting in a large field angle. A precision-engineered optic will control the light tightly. This difference is what separates an average product from a premium one. For your clients, this means the difference between a generic, washed-out space and a beautifully lit environment where the light is placed exactly where it's needed.

| Feature | Beam Angle | Field Angle | Why It Matters for Purchasing |

|---|---|---|---|

| Definition | Angle where light is >= 50% of max intensity | Angle where light is >= 10% of max intensity | Field angle reveals unwanted "spill light." |

| Effect | The bright, useful cone of light | Includes the main beam plus dimmer spill light | A small difference means higher quality optics. |

| Application | Defines the primary illuminated area | Affects overall ambient glare and visual "noise" | Crucial for clean, professional lighting designs. |

What is the beam angle for recessed lights?

You’re specifying hundreds of recessed lights6 for a project. Using a single "standard" beam angle for everything seems efficient but can easily ruin the entire design.

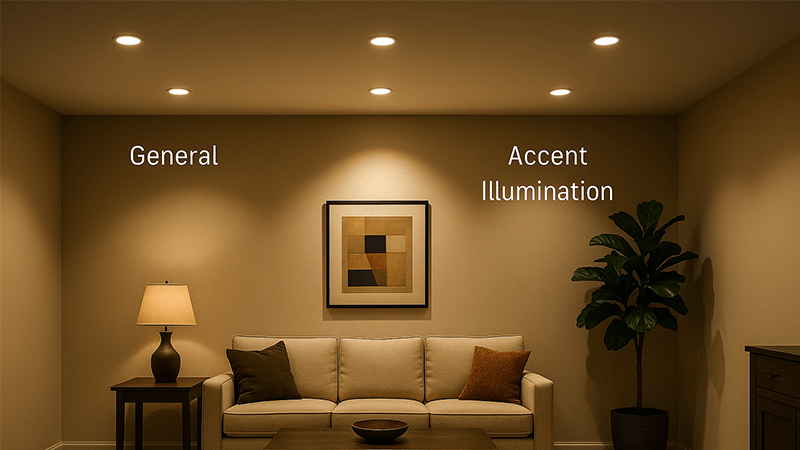

For general lighting in homes with standard ceilings (2.4-2.7m), 38° to 60° is ideal. For commercial accent lighting or high ceilings (3m+), use narrow beams from 15° to 25°. Kitchen task lighting works well with a medium 25°-38° beam. The application always dictates the choice.

The choice of beam angle for recessed lights6 has a direct impact on how bright a space feels and the commercial value7 it creates. It’s not just about the number of lumens a light produces; it’s about where those lumens are directed. Think about it this way: a 10W downlight with a 15° beam will create a much brighter spot on the floor than the exact same 10W downlight with a 60° beam. The narrow beam concentrates the light, increasing the lux level8 on the target. This principle is fundamental in retail and hospitality. In a jewelry store, you would use a very narrow beam (10°-15°) to make a diamond sparkle. In a restaurant, you might use a 25° beam on each table to create an intimate pool of light. On the other hand, a wide 60° beam is perfect for general lighting in an office corridor, providing smooth, even coverage.

Matching Beam Angle to Application

Your role is to secure the best value, and understanding this helps you guide your clients to better outcomes. Instead of selling a generic downlight, you can advise them on a lighting strategy9. By using a mix of beam angles, you can create layers of light that add depth and focus to a space. This elevates a simple installation into a sophisticated lighting design, which adds significant perceived value for the end user. It’s a powerful way to make your projects stand out.

| Application | Ceiling Height | Recommended Beam Angle | Desired Effect |

|---|---|---|---|

| General Lighting | 2.4m - 3m | 38° - 60° | Broad, even illumination for a whole room. |

| Task Lighting | 2.4m - 3m | 25° - 38° | Focused light over a specific work area. |

| Accent Lighting | 2.5m - 4m+ | 10° - 25° | Dramatic highlighting of art or features. |

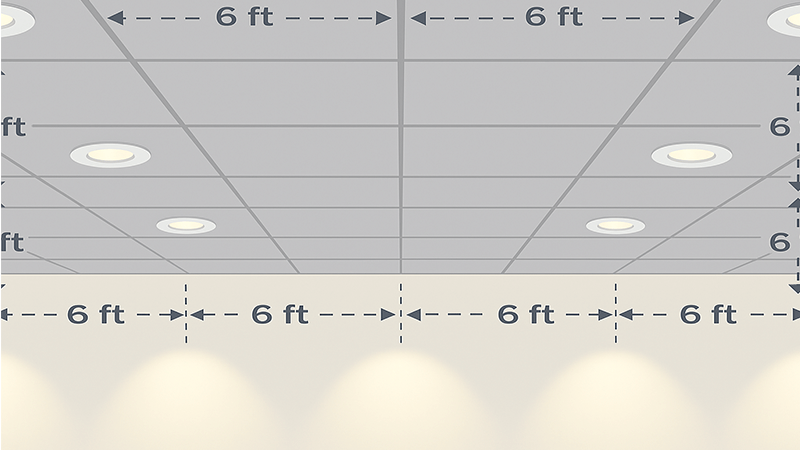

How should you position LED downlights?

You've selected the perfect beam angles for the job. But if you get the spacing wrong, the whole lighting design can fall apart, creating a visual mess.

The key is to space downlights at roughly half the ceiling height10. For example, in a room with a 2.6-meter ceiling, place your downlights about 1.3 meters apart. This "rule of thumb" ensures good overlap between beams for even coverage.

The relationship between beam angle, spacing, and glare is something I’ve spent years perfecting in our factory. They are all connected. A wider beam angle, like 60°, allows for greater spacing between fixtures because the cones of light are larger and will overlap more easily. However, this wider beam can also increase the Unified Glare Rating (UGR)11, as more of the light source is visible from different viewing angles. On the other hand, a narrow beam angle, like 24°, requires you to place the downlights closer together to avoid dark spots on the floor. The benefit is that a narrow beam, especially from a deep-recessed source, will have a much lower UGR, providing better visual comfort.

The Interplay of Spacing, Beam Angle, and Glare (UGR)

As a purchasing manager for large projects, you need to balance cost with comfort. Using fewer, wider-beam downlights might seem cheaper upfront. But if it results in a high-glare environment, it's a poor solution for an office or a school. The better strategy is often to use a slightly narrower beam angle (like 38°) with appropriate spacing. This provides a great balance of even coverage, visual comfort12 (low UGR), and reasonable cost. Always remember to push your supplier for UGR data, especially for commercial projects. It’s just as important as lumens or wattage.

| Beam Angle | Recommended Spacing (Ratio to Ceiling Height) | Typical UGR Effect | Best For |

|---|---|---|---|

| Narrow (24°) | Closer (e.g., 0.4x height) | Lower Glare (UGR <19 often achievable) | Task, Accent, High-Comfort Commercial Spaces |

| Medium (38°) | Standard (e.g., 0.5x height) | Moderate Glare (Good balance) | All-purpose Commercial and Residential Use |

| Wide (60°) | Wider (e.g., 0.6x - 0.7x height) | Higher Glare Risk (Careful placement needed) | General circulation areas, Corridors |

What is the future of lighting beam angles?

Specifying a fixed-beam downlight feels safe. But what happens when the client changes the room layout a year later? The lighting is now all wrong, a very costly problem.

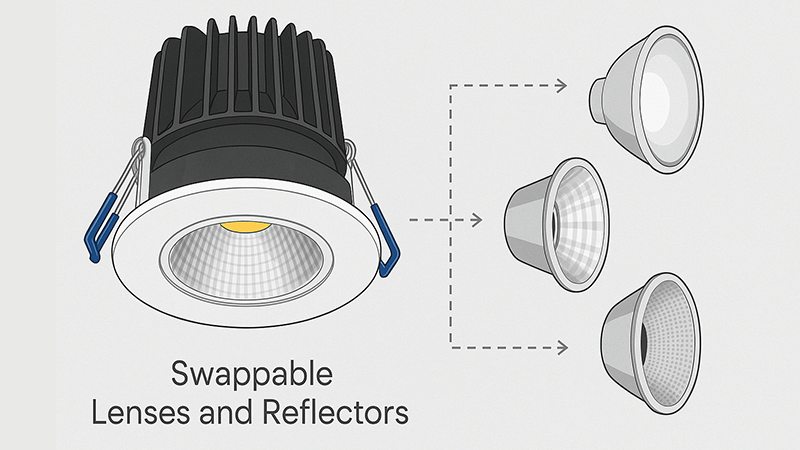

The future is modular optics13. Instead of fixed-beam luminaires, modern downlights allow you to swap the lens or reflector on-site. This provides ultimate flexibility and future-proofs your lighting investment against any changes in the space.

For years, we manufactured luminaires with fixed beam angles. If a client needed a 24° beam, we built them a 24° downlight. If they later decided they needed a 38° beam for the same space, they had to replace the entire fixture. This was inefficient and expensive for everyone. I knew we had to find a better way. This led us to develop modular optic systems. The core idea is simple: the LED engine and driver are separate from the optic. This means you can install one type of downlight across an entire project, and then customize the beam angle in each area simply by snapping in a new lens or reflector. This has been a game-changer for my clients.

Embracing Flexibility with Modular Optics

As a purchasing manager, this approach offers incredible value. First, it simplifies your inventory. You can stock one core downlight model and a selection of inexpensive optics, rather than dozens of different fixed-beam fixtures. This reduces complexity and saves money. Second, it future-proofs the project. An office space today might become a retail showroom tomorrow. With modular optics, you don't need to re-install the lighting. You just swap the lenses. This is a massive selling point that offers long-term value and sustainability. It moves the conversation from the initial cost of the fixture to the total cost of ownership14 over the building's lifetime, positioning you as a strategic partner, not just a supplier.

| Feature | Fixed-Beam Downlights | Modular Optic Downlights | Advantage for Purchasing Managers |

|---|---|---|---|

| Flexibility | Zero. The beam angle is permanent. | High. Beam angle can be changed on-site. | Adapts to client needs, future-proofs projects. |

| Inventory | High. Need to stock a fixture for every beam angle. | Low. Stock one fixture and multiple small optics. | Simplifies logistics and reduces stock value. |

| Cost | Lower initial unit cost. | Higher initial unit cost, but lower lifetime cost. | Offers better long-term value and upsell potential. |

| Sustainability | Wasteful. Whole fixture must be replaced for changes. | Sustainable. Only a small part is swapped. | Aligns with green building standards. |

Conclusion

Choosing the right beam angle involves more than a single number. It is about matching the angle, spacing, and technology to the specific application for a successful, high-value lighting project.

Understanding beam angle is crucial for achieving the desired lighting effect and avoiding glare. ↩

Proper spacing ensures even coverage and prevents dark spots in lighting design. ↩

Understanding spill light is essential for achieving clean and professional lighting designs. ↩

Photometric data reveals the true performance of lighting fixtures, ensuring quality. ↩

Superior optical engineering results in better control of light and reduced glare. ↩

Recessed lights can enhance a space when used correctly, improving aesthetics and functionality. ↩

Effective lighting design can significantly enhance the perceived value of a space. ↩

Lux level measures light intensity, crucial for ensuring adequate illumination. ↩

A well-defined lighting strategy enhances the overall design and functionality of a space. ↩

Ceiling height significantly influences the choice of beam angle and overall lighting design. ↩

UGR measures glare, which is crucial for visual comfort in lighting design. ↩

Visual comfort is essential for creating pleasant and functional environments. ↩

Modular optics provide flexibility and adaptability for changing lighting needs. ↩

Considering total cost of ownership helps in making sustainable and cost-effective choices. ↩