Choosing LED downlights seems simple, but the wrong choice leads to project failures, client complaints, and lost profits. You need to look beyond the basic product sheet.

To choose LED downlights, evaluate four key areas: light quality (CRI and spectrum), thermal management (heatsink design), visual comfort (anti-glare features), and system reliability (driver quality and compatibility). These factors determine long-term performance and client satisfaction.

Digging into a spec sheet can feel like a maze. Lumens, watts, CRI—these are just the beginning. As a manufacturer, I've seen firsthand that the most critical details are often the ones that are not listed. To truly select the right downlight, you have to understand what makes a fixture good from the inside out. Let's start with what truly defines a quality product.

How do I choose a good LED downlight?

You are afraid of choosing a downlight that looks good on paper but fails on-site. Flickering lights and incompatibility issues can destroy a project's profitability and your reputation.

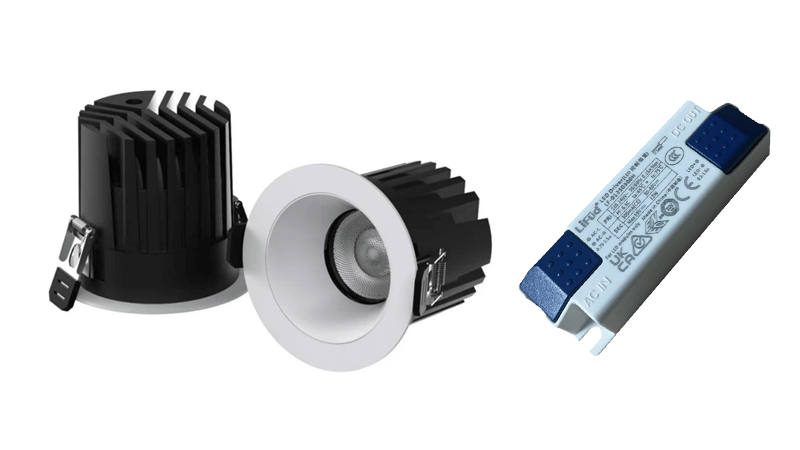

To choose a good LED downlight, focus on the driver. The driver is the heart of the fixture. A high-quality driver from a reputable brand ensures reliability, stable performance, and proper compatibility with control systems like dimmers, preventing most common failures.

Dive Deeper: Driver Compatibility is the New Reliability

For years, we focused on the LED chip's lifespan. Today, quality LEDs last 50,000 hours easily. The real point of failure has shifted. Now, the biggest problem I see in the field is the driver and its incompatibility with other systems. I remember a hotel project where the client specified a popular dimming system. The contractor installed downlights that were "dimmable," but used a cheap TRIAC driver. The result was a disaster. The lights flickered at low levels, and we had to replace every single driver.

The lesson was clear: driver compatibility1 isn't a feature; it's the foundation of a modern lighting project. Don't just ask if a downlight is dimmable. Ask how it dims.

| Dimming Protocol | Common Issues | Best For... | My Advice for Buyers |

|---|---|---|---|

| TRIAC (Phase-cut) | Flickering, buzzing, small dimming range. | Cheap residential retrofits. | Avoid for professional projects. It is old technology and unreliable with modern LEDs. |

| 0-10V / 1-10V | Requires extra control wiring. | Commercial projects, high-end homes. | A robust and reliable standard. A safe choice for most new builds requiring simple dimming. |

| DALI | Higher initial cost, requires programming. | Smart buildings, large commercial spaces. | The best for control and flexibility. Ask if the driver is certified to ensure compatibility. |

| Bluetooth / Zigbee | Interoperability between brands can be an issue. | Smart home systems, small offices. | Great for wireless control, but always test the fixture with the specified app or gateway first. |

As a purchasing manager, your best defense is to demand information about the driver. Ask for the brand, the warranty, and proof of compatibility with your specified control system. It's the most important question you can ask.

How do I know which downlights to buy?

It is confusing to select the right downlight for an office or home. You want a comfortable space, but many high-lumen lights create painful glare, making rooms unpleasant to be in.

To know which downlight to buy for a specific space, look for its anti-glare design features. A low Unified Glare Rating (UGR) is the goal, so choose fixtures with deep-set LEDs, darklight reflectors, or honeycomb louvers to ensure visual comfort.

Dive Deeper: The Glare Paradox and UGR

I often see spec sheets proudly claim "UGR2<19." This is one of the most misleading specs in our industry. Here's why: UGR is not a fixed attribute of a light fixture. It is a value calculated for an entire room. The calculation depends on the luminaire's light distribution, the room's size, the brightness of the walls and ceiling, and the viewer's position. A single downlight does not have a UGR value. So, when a supplier sells you a "UGR<19 downlight," they are being deceptive.

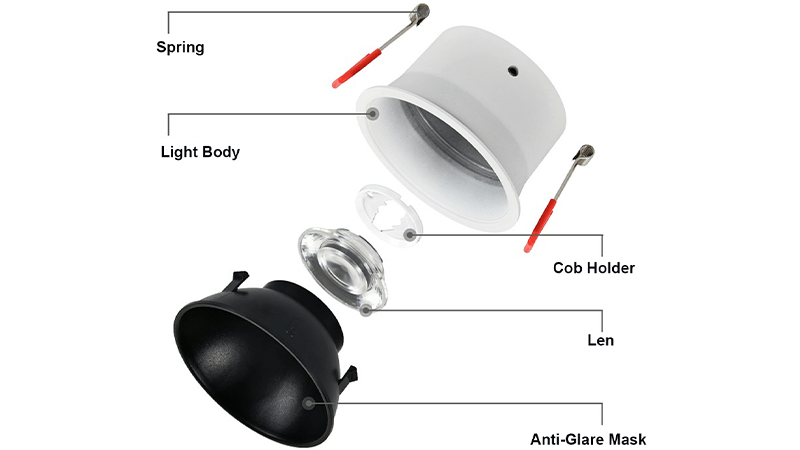

What they should be talking about are the design features that help achieve a low UGR in a finished space. When I am developing a new downlight for offices or homes, we focus on the physical design of the optic. This is what you should look for.

| Anti-Glare Feature | How it Works | Best Application |

|---|---|---|

| Deep-set COB | The LED chip is recessed far into the fixture, shielding it from direct view. | General purpose in offices, retail, and homes. A simple and effective method. |

| Black / Darklight Reflector | The inner reflector is painted black or has a special coating that absorbs stray light. | Areas where low glare is critical, like high-end lobbies, restaurants, and galleries. |

| Honeycomb Louver | A grid-like accessory that sits over the light source, blocking sight lines from high angles. | Task lighting, workstations, and art illumination where precise control is needed. |

Instead of asking for a "UGR<19 downlight," you will get better results by asking, "What is the cut-off angle?" or "Does this have a darklight reflector3?" These questions force the supplier to talk about physical design, not a misleading number. This is how you ensure true visual comfort4.

How many lumens should a downlight be?

You need to light a room, so you ask for high-lumen downlights. But this often results in a space that feels harsh and looks washed out, even though it's technically bright.

A typical downlight for general lighting is between 600-900 lumens. However, focusing on lumens alone is a mistake. The quality of the light, determined by its color spectrum, is far more important for creating a visually effective and pleasant environment.

Dive Deeper: The Deception of Luminous Efficacy

In the lighting industry, we are obsessed with luminous efficacy5, or lumens per watt (lm/W). Everyone wants the highest number possible, thinking it means a better, more efficient light. This is a dangerous trap. It is easy for a manufacturer to create a high lm/W LED by using chips that produce a lot of light in the yellow-green part of the spectrum, which our eyes are most sensitive to. The problem is that this light has a terrible spectrum. It lacks deep reds and rich blues, making skin tones look sickly and colors look flat.

True light quality6 comes from thoughtful spectral engineering. This means designing a light source that has a full, continuous spectrum, more like natural sunlight. This light might have a slightly lower lm/W figure, but the visual result is a thousand times better.

| Metric | High Efficacy / Low Quality Light | High Quality / Balanced Light |

|---|---|---|

| Luminous Efficacy | 130 lm/W | 100 lm/W |

| CRI / R9 Value | CRI 80 / R9 is 5 | CRI 95 / R9 is 80 |

| Spectrum | Spiky, with large gaps. | Full and continuous. |

| Visual Result | Technically "bright" but colors are dull, reds are brown, and the space feels sterile. | A rich, vibrant space where colors are true and people look healthy. More comfortable. |

The next time you are sourcing a project, challenge the obsession with lm/W. Ask for the R9 value7. Ask for a spectral power distribution8 (SPD) chart. A supplier focused on true quality will have this data. Excellent light is not just about brightness; it is about bringing a space to life with a full spectrum of color.

What is the rule for downlights?

You are trying to create a lighting layout and look for a simple rule. Many sources say to space downlights based on their beam angle, but this often leads to uneven lighting or dark spots.

A common rule is to space downlights at a distance equal to half the ceiling height. However, the most important rule for long-term performance is to ensure the downlight has excellent thermal management, as this dictates its lifespan and light consistency.

Dive Deeper: Thermal Management is a Pathway, Not a Component

Every spec sheet mentions the heat sink, usually listing its material as "aluminum." This tells you almost nothing. I've taken apart competitor products that failed after only a year, despite having a big, heavy aluminum heat sink. The problem wasn't the material; it was the design of the entire thermal pathway9. Heat needs a clear, uninterrupted path to travel from the tiny LED chip to the surrounding air. Any bottleneck in this path will trap heat and cook the LED, causing it to dim prematurely or fail completely.

A good thermal pathway is a system. It's not just one component.

| Pathway Component | Poor Design (Common) | Excellent Design (Pro-Grade) | Why it Matters for Longevity |

|---|---|---|---|

| LED Board (MCPCB) | Thin aluminum board with low thermal conductivity. | Copper or high-grade aluminum board. | Copper pulls heat away from the LED chip much faster, which is the critical first step. |

| Thermal Interface (TIM) | Cheap, dry thermal pad or thick grease. | High-quality thermal paste, applied thinly and evenly. | Fills microscopic air gaps between the board and heat sink. Poor TIM creates a major heat bottleneck. |

| Heatsink | Thick, heavy fins with little surface area. | Thin, well-spaced fins designed for convection airflow. | It's not about weight; it's about surface area. Good design allows air to move freely and carry heat away. |

The real "rule" for downlights is that their long-term performance is dictated by how well they get rid of heat. When sourcing, ask about the design. Ask if they use a copper MCPCB10. Ask what brand of thermal paste they use. A manufacturer who has thought about the entire thermal pathway9 is one who is building a product to last.

Conclusion

To choose the right LED downlight, look past the surface specs. Prioritize the driver, anti-glare design11, light spectrum quality, and the entire thermal pathway for a truly successful project.

Explore how driver compatibility affects the functionality and reliability of lighting systems. ↩

Learn about Unified Glare Rating and its impact on creating comfortable lighting spaces. ↩

Discover how darklight reflectors can enhance visual comfort and reduce glare in lighting. ↩

Learn about design features that enhance visual comfort and reduce glare in lighting environments. ↩

Understanding luminous efficacy helps in selecting efficient and high-quality lighting solutions. ↩

Understanding light quality is crucial for ensuring optimal performance and client satisfaction in lighting projects. ↩

Understanding R9 value helps in selecting lights that render colors accurately and beautifully. ↩

Learn how spectral power distribution influences the quality of light in various applications. ↩

Learn about the importance of thermal pathways in ensuring the longevity of LED fixtures. ↩

Learn how copper MCPCB enhances heat dissipation and improves the longevity of LED downlights. ↩

Discover how anti-glare features can improve visual comfort and reduce eye strain. ↩