Choosing downlights for an airport seems straightforward, right? You worry about defects causing massive replacement costs. The hidden issues in lighting are what truly impact your project's success.

To choose the best LED downlights for airports, focus on five key factors beyond the spec sheet: CCT and CRI consistency, thermal management design, driver reliability, fire-rated materials, and ease of installation. These determine long-term performance, safety, and maintenance costs.

Choosing lighting for a large-scale project like an airport is a huge responsibility. It goes far beyond just lumens and wattage. The decisions you make affect safety, passenger experience, and operational budgets for years to come. I've spent my career on the factory floor and in boardrooms, and I've seen how small details in manufacturing can lead to big problems later. Let me share what I've learned, so you can avoid the common pitfalls and select products that deliver real quality. The true cost of a light fitting isn't its purchase price; it's the cost of it failing. Let's look at what really matters.

Can you bring LED lights on a plane?

Wondering if you can pack that new LED lamp in your luggage? Many travelers are unsure about the rules. It feels like a simple question, but airline security can be tricky.

Yes, you can generally bring LED lights and bulbs in both carry-on and checked baggage. Since they don't contain hazardous materials like older fluorescent bulbs, they are not considered a security risk. However, always check with your specific airline for their latest regulations.

The Hidden "Quality" Killer: Color Consistency

While you can easily bring a personal LED light through an airport, specifying thousands of lights for an airport is a different challenge entirely. The biggest issue I see is consistency. For a purchasing manager like Shaz, ensuring uniformity across a massive space is critical. A client of mine in the UAE once faced a nightmare scenario. They sourced downlights from two different batches for a large commercial hall. The result? The ceiling looked like a patchwork quilt of slightly different shades of white. It was a visual disaster1 that required a costly replacement2. This highlights the hidden killer of light quality: poor consistency in Color Temperature (CCT)3 and Color Rendering Index (CRI)4. For airports, you need every single downlight to look identical. This is only possible through tight control during manufacturing, specifically in LED binning5. We only accept LEDs binned within a 3-step MacAdam ellipse to guarantee that a 3000K downlight looks exactly like every other 3000K downlight in the order. Inconsistent CRI is also a problem. A CRI of 80 should be a true 80, not fluctuating between 75 and 83. This consistency is what separates a professional-grade product from a cheap alternative. It is not something you a can see on a spec sheet, it is something you must require from your manufacturer.

Which light is used in an airport?

Airports are massive, complex environments with diverse needs. You might think one type of light fits all, but that can lead to poor visibility, high energy bills, and a bad passenger experience.

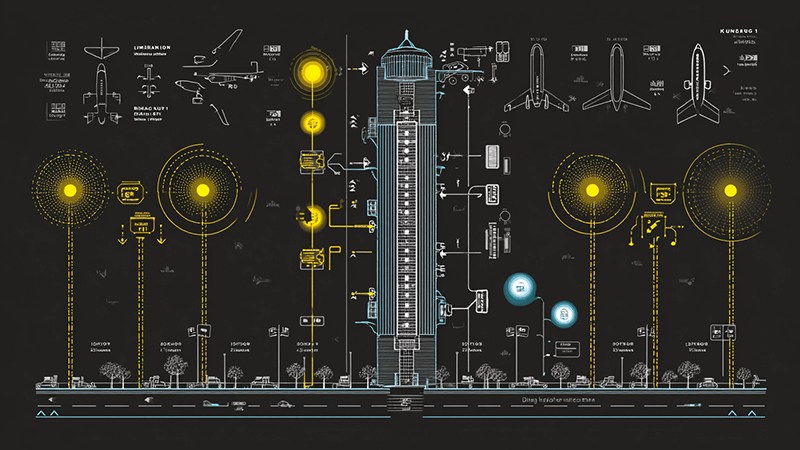

Airports use a wide variety of lights, but LED technology is dominant. In terminals, LED downlights, panel lights, and linear fixtures are common for general and accent lighting. On the airside, specialized high-mast and apron floodlights6 are used for runways and taxiways.

The Hidden "Lifespan" Killer: Thermal Management

We've established that airports use many lights, with LED downlights being key in terminals. But not all downlights are created equal. The single most important factor for an LED's lifespan is its thermal management. I've seen countless fixtures fail prematurely simply because of poor heat sink design. LEDs generate heat, and if that heat isn't drawn away effectively, the LED chip degrades rapidly. This leads to a drop in brightness, a shift in color, and eventual failure. When I evaluate a downlight, the first thing I do is pick it up. I feel the weight and construction of the heat sink. A flimsy, lightweight heat sink is a major red flag. For our products at iPHD, we use cold-forged aluminum, which offers superior thermal conductivity compared to the cheaper die-cast aluminum many competitors use. This design choice directly impacts the Luminous Flux Maintenance7, or how well the light maintains its brightness over time. A good downlight should maintain at least 80% of its initial brightness after 50,000 hours (L80B10). This is only achievable with excellent thermal design. Ask your supplier for thermal simulation reports and insist on high-quality materials for the heat sink. This is the difference between a light that lasts 5 years and one that lasts 10.

| Heat Sink Material | Thermal Conductivity (W/mK) | Manufacturing Process | Common Use |

|---|---|---|---|

| Pure Aluminum (1070) | ~229 | Cold Forging / Extrusion | High-End LED Lighting |

| Die-Cast Aluminum (A380) | ~96 | Die Casting | Standard/Budget LED Lighting |

| Plastic/Polymer | <1 | Injection Molding | Low-Power / Low-Cost Bulbs |

What are the different types of airport lighting?

Thinking about lighting an airport seems overwhelming. There are so many different areas, each with unique requirements. Using the wrong light in the wrong place can compromise safety and efficiency.

Airport lighting is categorized by its location and function. This includes airside lighting (runway, taxiway, and apron lights), landside lighting (terminal, parking, and roadway lights), and ancillary lighting for security, signage, and emergency systems. Each type has specific performance and regulatory standards.

The Hidden "Reliability" Killer: The Driver

Among all the types of airport lighting, the fixtures inside the terminal, like downlights, run for thousands of hours a year. Here, the hidden point of failure is almost always the driver, or power supply. The LED chip itself can last for 50,000 or even 100,000 hours, but a cheap driver will fail long before that. When a driver fails, the light goes out. In an airport with ceilings 10 meters high, replacing a single failed downlight is a major operation involving special lifts and disrupting operations. Now imagine hundreds of failures. The maintenance cost becomes astronomical. This is why I tell my clients to obsess over the driver quality. We partner with top-tier brands like Tridonic and OSRAM because their drivers are built with high-quality components8 and undergo rigorous testing. They have better surge protection9, a lower failure rate, and a much longer operational life. A good driver also has a low ripple current10, which prevents the invisible flicker that can cause eye strain and headaches for passengers and staff. For large projects, specifying a premium, external driver is the single best investment you can make for long-term reliability. An extra $5 for a top-brand driver can save you $100 in future maintenance costs.

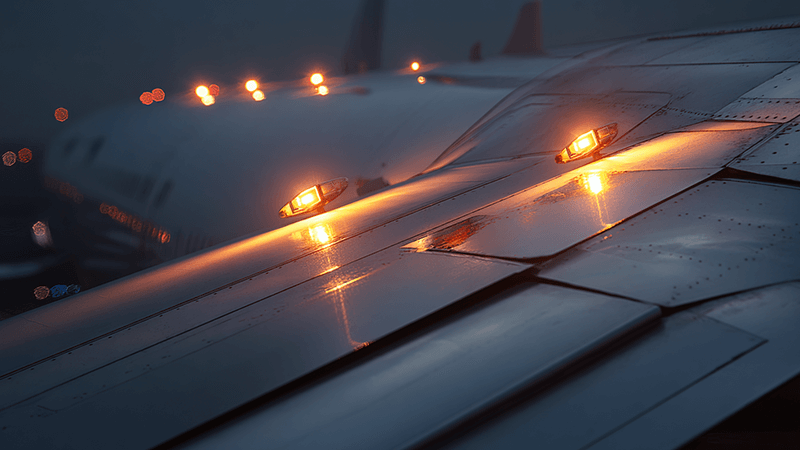

What are the FAA lighting requirements11 for aircraft?

Pilots rely on a precise system of lights to navigate safely. You might wonder what standards govern these critical lights. Getting them wrong isn't an option; it's a matter of life and death.

The FAA has strict requirements for aircraft lighting, covering position lights (red, green, white), anti-collision beacon lights, and landing lights. These standards dictate intensity, color, light field, and flash rates to ensure aircraft are visible and their orientation is clear to other pilots and ground control.

Hidden Dangers: Fire Safety & Maintenance Costs

Just as the FAA governs aircraft lighting for safety, building codes govern the lighting inside airport terminals. Here, two often-overlooked factors create huge hidden risks and costs: fire safety and maintenance design. In the event of a fire, a ceiling can collapse, and fire can spread through cutouts made for downlights. This is why using fire-rated downlights is non-negotiable in many airport areas. A fire-rated downlight is designed to seal the hole in a fire-rated ceiling for up to 90 minutes, slowing the spread of fire and smoke. The materials used in the fixture itself are also critical. We insist on using polycarbonate (PC)12 that has a high V-0 flammability rating, meaning it self-extinguishes quickly and doesn't propagate fire. Cheap fixtures often use lower-grade plastics that can be an accelerant.

Beyond fire safety, the physical design impacts long-term maintenance costs. A purchasing manager like Shaz needs to think about the total cost of ownership. How easy is it to install and replace the light? A downlight with a simple plug-and-play connector13 between the driver and the fixture allows maintenance staff to swap a unit in minutes without complex electrical work. A poorly designed fixture might require the entire unit, including the driver, to be unwired and removed, dramatically increasing labor time and cost. Small design choices, like robust springs and quick-connect terminals14, make a world of difference when you're maintaining thousands of lights.

Conclusion

Choosing airport downlights is about ensuring long-term reliability. Focus on consistency, thermal design, driver quality, and safety ratings to avoid hidden costs and guarantee a successful, lasting project.

Learn how poor lighting choices can lead to aesthetic and operational issues in airport environments. ↩

Understanding replacement costs can help in selecting durable and reliable lighting solutions. ↩

Explore the significance of Color Temperature in creating the right ambiance in airport environments. ↩

Understanding CRI is vital for ensuring accurate color representation in airport lighting. ↩

Learn about LED binning and how it affects color consistency in lighting applications. ↩

Discover the role of specialized lighting in enhancing safety and visibility on airport runways. ↩

Understanding Luminous Flux Maintenance helps in selecting downlights that maintain brightness over time. ↩

Explore the importance of high-quality components in ensuring the reliability of LED drivers. ↩

Learn how surge protection can prevent driver failures and extend the life of airport lighting systems. ↩

Understanding low ripple current can help prevent flicker and improve passenger comfort in airports. ↩

Explore the FAA's strict lighting standards to ensure safety and compliance in aviation. ↩

Learn about the advantages of using polycarbonate in lighting fixtures for enhanced safety. ↩

Discover how plug-and-play connectors simplify maintenance and reduce downtime in airport lighting. ↩

Learn how quick-connect terminals can streamline installation and maintenance processes. ↩