Picking the right LED downlight can be confusing. You see high wattage numbers and assume they mean better light, but this often leads to paying more for less.

To choose the right wattage, focus on lumens (brightness) and luminous efficacy (lm/W), not just the wattage itself. For most commercial spaces, 8-15 watts with high efficacy (over 100 lm/W) is ideal. Always check the lumen output to ensure it meets your project's needs.

Looking at wattage is a habit from the old days of incandescent bulbs. But in the world of LEDs, wattage tells a very different, and sometimes misleading, story. I have seen many clients make costly mistakes by focusing only on this number. Let's break down what really matters so you can make smarter purchasing decisions for your projects. You need to understand the secrets that some suppliers don’t want you to know.

What wattage is best for LED downlights?

You’re trying to find the best downlight and the specs list different wattages. It seems simple to just pick a higher number, but you worry it might be wrong.

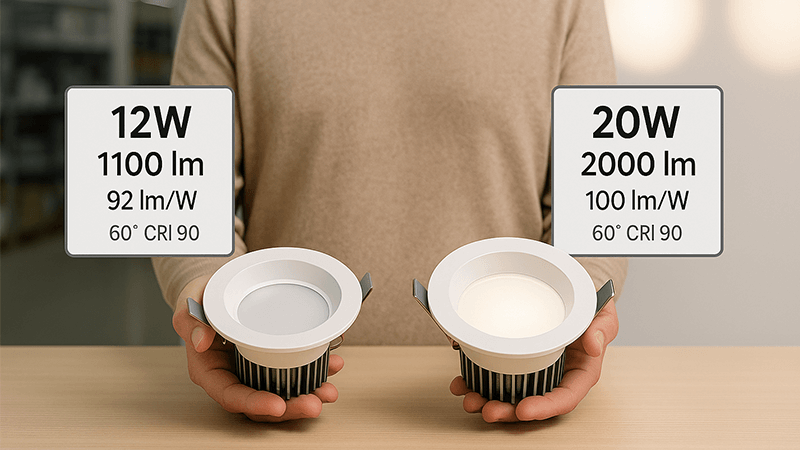

The best wattage is the one that delivers the required lumens for your space with the highest efficiency. For general office lighting, 8-12W is often sufficient. For retail or high-ceiling areas, you might need 15-25W. The key is to check the lumen output first.

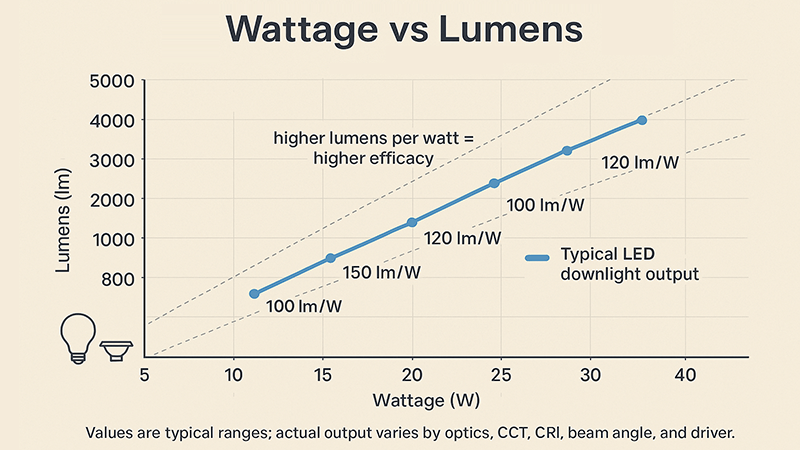

In my years of manufacturing, the biggest myth I have to bust is that wattage1 equals brightness2. It does not. Wattage (W) only measures how much electricity the light consumes. The real measure of brightness is lumens3 (lm). The secret is to look at the relationship between these two numbers, which is called luminous efficacy4.

The Real Secret: Luminous Efficacy

Luminous efficacy is measured in lumens per watt (lm/W). This number tells you how efficiently a downlight converts electricity into light. A high-quality light will have a high efficacy rating. For example, a quality 10W downlight from my factory can produce 1200 lumens. That's an efficacy of 120 lm/W. I have seen some clients consider a cheaper 15W light that only produces 1200 lumens. Its efficacy is only 80 lm/W. My light is brighter and uses less energy. In a large project with hundreds or thousands of downlights, this difference in efficiency adds up to huge energy savings5.

Matching Wattage to Application

You need to choose the wattage based on what the space is used for and the height of the ceiling. Here is a simple guide I share with my partners.

| Application Area | Ceiling Height | Recommended Wattage Range | Recommended Lumens |

|---|---|---|---|

| Office/Corridor | Standard (2.4-3m) | 8W - 12W | 800 - 1200 lm |

| Retail/Showroom | Standard (2.4-3m) | 12W - 20W | 1200 - 2000 lm |

| Lobby/High Ceiling Area | High (3-5m) | 15W - 25W | 1500 - 2500 lm |

| Task Areas (e.g., reception desk) | Standard (2.4-3m) | 10W - 15W | 1000 - 1500 lm |

Always start by asking your supplier for the lumen output and efficacy data sheet, not just the wattage. This shifts the power back to you, the buyer.

What happens if wattage is too high?

You've found a very high-wattage downlight and think it will solve your brightness problems. But using a light with excessive wattage can create new issues you didn't expect.

If the wattage is too high, it creates excessive heat. Poorly designed lights cannot handle this heat, causing the LED chip to degrade quickly. This leads to rapid light decay, color shifts, and a much shorter lifespan for the downlight, wasting your investment.

The temptation to use high-wattage lights is strong, especially for spaces that need to be bright. But from a manufacturer's perspective, I can tell you that high wattage is the enemy of a long-lasting LED product if it is not managed correctly. Heat is the number one killer of LEDs.

The Link Between Heat and Light Decay

Every watt of electricity consumed by an LED produces heat as a byproduct. A higher wattage means more heat is generated in a small space around the LED chip. The entire design of the downlight, especially the heat sink, must be able to pull this heat away from the chip effectively.

At my factory, iPHD, we spend a lot of time engineering our heat sinks. We use pure aluminum and design fins that maximize surface area to dissipate heat into the air. Cheaper lights often use inferior materials or have a small, ineffective heat sink. When you use a high-wattage downlight with a poor heat sink, the chip's temperature can go way above its safe operating limit. This constant overheating causes the materials inside the LED to break down. The result is called "lumen depreciation6," or light decay. The light gets dimmer much faster than it should. I've seen lights lose 30% of their brightness in just one year.

Beyond a Dimmer Light

The problems don't stop at just losing brightness. Excessive heat can also cause other issues.

- Color Shift: The color of the light can change. A nice neutral white light might start to look yellow or even greenish over time. This is a disaster for retail spaces where color accuracy is important.

- Driver Failure: The electronic driver that powers the LED is also sensitive to heat. Overheating can cause the driver to fail completely, and the light will stop working altogether.

- Fire Hazard: In extreme cases, a very poorly made, high-wattage light can be a safety risk.

So, when you see a very high-wattage downlight, especially at a low price, be very suspicious. Ask the supplier about their thermal management7 design. A good supplier will be proud to explain it.

What is the rule of thumb for downlights?

You need a simple, reliable rule to guide your purchasing decisions without getting lost in technical details. You just want a quick way to check if a product is good.

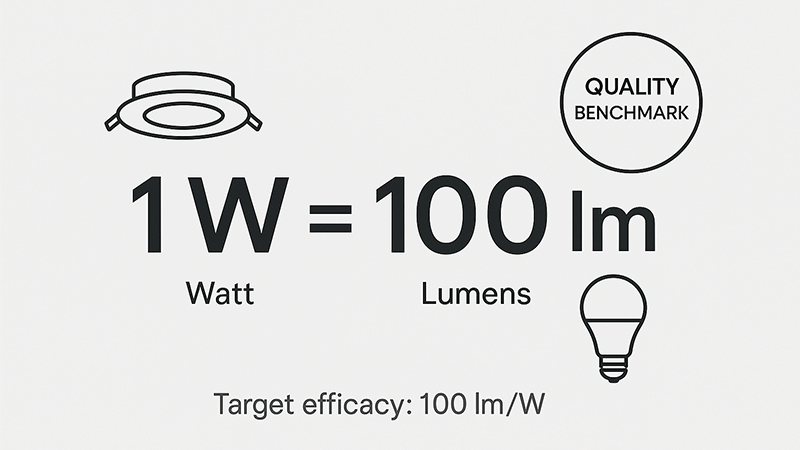

A good rule of thumb is the "100 Lumens per Watt" rule. If a downlight offers at least 100 lm/W, it's generally an efficient, modern product. Also, check the warranty; a 3- to 5-year warranty indicates the manufacturer trusts their own quality.

I work with purchasing managers like Shaz every day, and I know they are busy. They need simple rules to quickly sort good suppliers from bad ones. Over the years, I've developed a few simple checks that can save you a lot of trouble. These rules help you look past the marketing and see the real quality of the product.

My Personal Checklist for Quality

When I evaluate a downlight, even one from a competitor, I use this mental checklist. It has served me and my clients well.

1. The 100 lm/W Efficacy Rule: I already mentioned this, but it's the most important rule. If you divide the total lumens by the total watts and the result is less than 100, the technology is likely old or the components are cheap. For my brand, iPHD, we aim for 110-130 lm/W or higher in our new products. A higher number means better technology and more energy savings.

2. The Power Factor Check: Ask for the Power Factor (PF). It should be greater than 0.9. Power Factor tells you how effectively the light uses the electricity supplied to it. A low PF (like 0.5) means that a lot of energy is wasted in the circuit. This wasted energy doesn't produce light but still costs you money on the electricity bill. It's a sign of a very cheap, inefficient driver.

3. The "Real" Wattage Test: This is an industry secret. Many factories engage in "inflated labeling." They'll label a light as 10W, but when you test it, it only draws 8W. It's a simple way for them to use a cheaper driver and chip while still claiming a higher spec. If possible, ask for a sample and have it tested by a third party. If you see a big difference between the labeled wattage and the tested wattage, it is a major red flag. It shows the supplier is dishonest.

4. The Warranty Trust Signal: A warranty8 is a promise. A manufacturer that offers a 1- or 2-year warranty is telling you they don't expect the light to last very long. A 3-year or, even better, a 5-year warranty shows confidence. This confidence usually comes from using better components and better thermal management. They are willing to stand behind their product because they know it is built to last.

How do I calculate how many LED downlights I need?

You're planning a layout for a new office or shop. You need to know exactly how many downlights to order to get the right brightness level without creating dark spots.

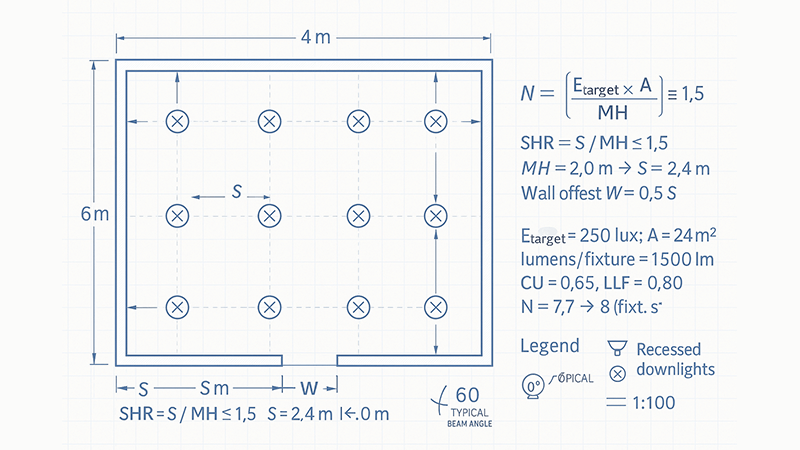

First, determine the required brightness (in lux) for your space. Then, multiply the room's area (in square meters) by the required lux level9 to get the total lumens needed. Finally, divide this total by the lumen output of a single downlight.

Calculating the number of fixtures is something that separates a professional lighting plan from guesswork. Getting it right means a perfectly lit space that feels comfortable and functional. Getting it wrong leads to complaints, poor productivity, or lost sales. While a full lighting design10 using software like DIALux is best for complex projects, you can use a simple formula for most standard rooms.

A Step-by-Step Calculation Guide

Let's walk through an example. Imagine you are lighting a small office that is 5 meters long and 4 meters wide.

Step 1: Find the Area of the Room The area is simply length times width.

- Area = 5 m x 4 m = 20 square meters (m²)

Step 2: Determine the Required Lux Level Lux is the measurement of light intensity on a surface. Different tasks require different lux levels. Here are some common standards.

| Space Type | Recommended Lux Level (on task surface) |

|---|---|

| General Office / Classroom | 300 - 500 lux |

| Corridor / Stairway | 100 - 150 lux |

| Retail Store (general) | 500 - 750 lux |

| Supermarket | 750 - 1000 lux |

| Warehouse (storage) | 100 - 200 lux |

For our office example, let's aim for a bright 400 lux.

Step 3: Calculate the Total Lumens Needed Now, you multiply the area by the required lux level.

This is the total amount of light that needs to reach the desks and floor in that office.

Step 4: Choose Your Downlight and Divide Let's say you've chosen a high-quality 10W downlight that produces 1200 lumens. Now, you just divide the total lumens needed by the lumens of one fixture.

- Number of Downlights = Total Lumens / Lumens per Downlight

- Number of Downlights = 8,000 lm / 1200 lm = 6.67

Since you can't install 0.67 of a light, you would round up to 7 downlights to ensure the space is bright enough. You can then arrange these 7 lights evenly across the ceiling to provide consistent coverage.

Conclusion

Choosing the right wattage is not about picking the biggest number. It is about understanding lumens, efficacy, and heat to ensure you get efficient, reliable, and long-lasting light for your project.

Discover why wattage alone is misleading when choosing LED lights. ↩

Explore the different ways brightness is quantified in lighting. ↩

Understanding lumens is crucial for selecting the right brightness for your space. ↩

Learn how luminous efficacy affects energy efficiency and light output. ↩

Find out how choosing the right LED can reduce your energy bills. ↩

Learn about lumen depreciation and its impact on light quality over time. ↩

Understand how effective thermal management can prolong LED lifespan. ↩

Discover how warranty length reflects the quality and reliability of LED products. ↩

Find out the ideal lux levels for various environments to ensure proper lighting. ↩

Explore how proper lighting design enhances functionality and aesthetics. ↩