Concerned that unpredictable shipping times could delay your project? Unclear lead times can halt projects and inflate costs. Understanding the full process helps you plan better and avoid costly surprises.

For bulk LED downlight orders from China, expect a total lead time of 45-75 days. This includes production (25-45 days), quality control, and shipping (20-30 days). Planning ahead and clear communication with your supplier are essential for timely delivery and avoiding project setbacks.

Getting your lights on time is crucial for any project. But what really goes into that "lead time" figure? It's more than just the time on a ship. The total time involves many steps, from confirming your order details to the final delivery at your warehouse. Understanding each stage helps you manage your projects with confidence and avoid expensive hold-ups. Let's break down the entire journey from order to delivery so you are never caught off guard.

Is lead time time to get supply after ordering?

You see "lead time" on a quote, but what does it mean? Is that when it's ready to ship, or when it arrives? This confusion can destroy your entire project schedule.

Yes, lead time is the total time from when you officially place an order until the supply is in your hands. It covers every step: pre-production approvals, manufacturing, quality checks, packaging, and the final shipping journey to your designated delivery point. It's the complete picture.

When a supplier gives you a lead time, it’s easy to think of it as just one block of time. But in my experience, it's really a series of connected stages, and a delay in one can have a big impact on the final delivery date. Knowing these stages helps you ask the right questions and manage your project timeline much more effectively.

The Stages Inside the Total Lead Time

Let's look at what actually happens after you send that purchase order. The process is not as simple as "order in, product out." It's a detailed workflow.

| Stage | Typical Duration | Key Activities & Potential Delays |

|---|---|---|

| 1. Pre-Production | 3-7 Days | Finalizing technical specs1, drawing approvals, payment confirmation. |

| 2. Manufacturing | 20-35 Days | Sourcing materials, component production, assembly line work. |

| 3. Quality & Packaging | 2-3 Days | Product testing, quality control2 inspection, custom packaging3. |

| 4. Shipping | 20-30+ Days | Inland transport, customs clearance4, sea/air freight, final delivery. |

Why Pre-Production Details Are Critical

This first stage is where many preventable delays happen. We need to confirm every detail before a single downlight is made. I remember a project for a client in Dubai. He needed downlights for a new office building. Everything was on a tight schedule. We almost started production, but during our final confirmation call, we double-checked the cutout-hole dimension5. It turned out the initial spec was off by 5mm. It seems small, but it's the difference between a perfect fit and an unusable product. Catching this saved a huge headache and a costly delay, but it shows how vital this step is. If we had started production, the entire order would have been wrong, adding weeks to the lead time for a complete re-run. This is why we are so careful with these early details.

How do you calculate lead time for order to delivery?

You have a project deadline and need to know exactly when your lights will arrive. Guessing isn't an option. How do you get a reliable date for your project plan?

To calculate total lead time, you add up the time for each separate stage: Production Time + Quality Control Time + Shipping Time. Always ask your supplier for a breakdown of these numbers and add a 5-10 day buffer for potential customs or transit delays.

Calculating the total lead time6 isn't just simple addition. You need to understand the variables within each part of the equation. As a manufacturer, I see where things can speed up or slow down. Your final delivery7 date depends on how well these stages are managed. It is my job to make this process transparent for my partners.

The Lead Time Calculation Formula

The basic formula is straightforward, but the details inside each component are what matter for an accurate forecast.

Total Lead Time = (P) + (Q) + (S)

- P = Production Time: The time to actually make the products.

- Q = Quality Control & Packing Time: The time for inspections and getting orders ready for shipment.

- S = Shipping Time: The time for transit from the factory to your door.

Let's explore what influences each of these factors.

Factors That Influence the Calculation

1. Production Time (P): This is often the longest part of the lead time. It's not just about assembling parts. It starts with sourcing raw materials like aluminum for the heat sink and high-quality LED chips. If you need a specific type of driver or a custom color temperature, this can add time. One key issue I've seen cause problems is batch-to-batch color consistency8. For large projects, you need every single downlight to have the exact same color temperature. If you place an order today, and another one in two months, you need to be sure the light color matches perfectly. A good manufacturer controls this by using chips from the same bin. A less reliable one might not, leading to visible differences that look terrible when installed. We always confirm and reserve materials for large projects to guarantee this consistency, which is a key part of our production planning.

2. Quality Control & Packing (Q): This stage is short but critical. After production, every unit should be tested. We do aging tests, power-on tests, and check the light output. Skipping this to save a day or two is a recipe for disaster. This is also where custom packaging3 is handled. Clear labeling and strong boxes prevent damage and confusion at your warehouse.

3. Shipping (S): This is often the most unpredictable part. It includes getting the container to the port, clearing Chinese customs, the sea journey, and clearing customs in your country. A single missing document can hold a container for weeks. Working with an experienced supplier who handles the paperwork correctly is essential.

What is the lead time for shipping?

You've been told production9 is finished. Now, how long until the boxes are at your warehouse? The factory part is done, but the journey has just begun.

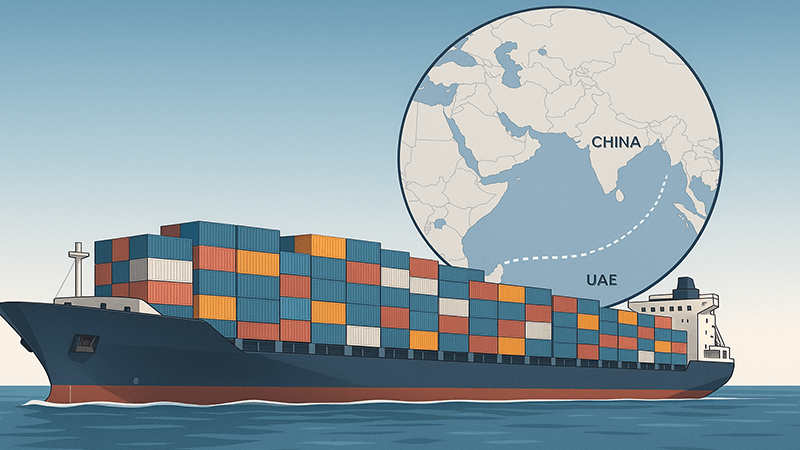

The shipping lead time itself—from the factory door in China to your warehouse—is typically 20-30 days for sea freight to regions like the UAE. This timeframe includes inland trucking in China, port operations, ocean transit, customs clearance, and local delivery.

When my clients, like Shaz, ask about shipping time, they are asking about the final leg of the journey. Once the downlights are produced, tested, and packed, our focus shifts entirely to logistics. The goal is to get the products moving as quickly and safely as possible. This part of the process has its own set of steps and potential delays that are completely different from manufacturing.

Breaking Down the Shipping Journey

The 20-30 day estimate for shipping10 isn't just the time the vessel spends at sea. It's a multi-step process that requires careful coordination.

| Shipping Stage | Typical Duration | Notes & What Can Go Wrong |

|---|---|---|

| Inland China Trucking | 1-3 Days | Getting the container from our factory to the port (e.g., Shenzhen, Ningbo). |

| Port & Export Customs | 2-4 Days | Loading container, processing export documents. Delays can occur during peak season or inspections. |

| Ocean Freight | 15-20 Days | The actual time the ship is sailing from China to a port like Jebel Ali in the UAE. |

| Import Customs & Port | 2-5 Days | Unloading, customs clearance4 at the destination. Document errors are a major cause of delays here. |

| Final Delivery | 1-3 Days | Trucking the container from the destination port to your warehouse or project site. |

The Critical Role of Installation Knowledge in Shipping

You might wonder how product knowledge connects to shipping. It’s about planning the right shipment. I once worked with a contractor on a large residential project. They needed smart dimmable downlights. During our pre-production talks, I learned it was a renovation of an older building. I immediately asked, "Have you confirmed the wiring?" Smart downlights often require a pre-wired neutral line or specific control wires. The contractor hadn't realized this. If we had just shipped the standard smart downlights, they would have been useless. The installation would have required tearing open walls to run new wires, causing massive delays and costs. By asking this upfront, we switched the order to a different type of smart downlight that works with older 2-wire systems. We shipped the right product, and the project stayed on schedule. This is how deep product knowledge prevents "shipping" the wrong solution, which is the worst delay of all.

What is the lead time after placing order?

You've just sent the purchase order and payment. The clock has officially started. So, what happens now, and when can you realistically expect your downlights to be ready?

Right after you place an order, the lead time begins with a 3-7 day pre-production phase for confirming technical drawings and specs. After that, expect the manufacturing lead time11 to be around 20-35 days before the goods are ready to ship.

The moment an order is confirmed is exciting, but it also kicks off a series of crucial internal processes here at the factory. This initial period, right after you've placed the order, sets the foundation for the entire production run. Getting this part right is essential for a smooth and timely delivery. It’s not just about starting the assembly line; it's about making sure we are building the exact product you need.

The First Two Weeks: From Order to Production

The first part of the lead time is the most communication-heavy. It's where we finalize all the details to prevent any misunderstandings down the line.

Week 1: Confirmation and Finalization This week is all about double-checking the specifications. We create and send you a final technical drawing or "golden sample" specification sheet. This document locks in every detail:

- Exact Dimensions: Including the critical cutout size.

- Ceiling Depth Requirements: This is a surprisingly common issue. Many modern downlights need more than 7cm of clearance in the ceiling void for proper heat dissipation. I had a client who ordered 1,000 downlights without checking this. When the installers arrived, the ceiling was too shallow. The lights either didn't fit or would have overheated, creating a fire hazard. We had to rush a new order of our slim-profile series for them. Now, confirming the installation depth is a mandatory checkpoint in our process before we start any production run.

- Light Characteristics: CCT (e.g., 3000K, 4000K), CRI, and beam angle.

- Driver Specifications: Dimmable, non-dimmable, brand, etc.

Week 2: Material Preparation and Scheduling Once you approve the final specs, we move to the next stage. We don't keep all components for all possible variations in stock. This week is for:

- Sourcing Raw Materials: Ordering the specific LED chips, drivers, and aluminum needed for your order.

- Production Scheduling: Your order is placed into the factory's production schedule. The complexity of your order and how busy the factory is can influence how quickly it gets onto the line.

This careful two-week process ensures we make the right product correctly the first time. Rushing these steps is the most common reason for production errors and, ultimately, much longer delays than taking the time to confirm everything at the start.

Conclusion

Understanding the full lead time, from order confirmation to final delivery, is key. It involves production, quality control2, and complex shipping logistics. Clear communication with your supplier prevents delays.

Learn about the significance of technical specifications in ensuring product accuracy. ↩

Find out how quality control ensures product reliability and prevents costly delays. ↩

Discover how proper packaging can prevent damage and ensure timely delivery. ↩

Learn about the customs clearance process and its impact on delivery schedules. ↩

Explore how cutout-hole dimensions affect installation and product fit. ↩

Learn about the components of total lead time and how to manage it effectively for your projects. ↩

Explore the factors that can impact final delivery times and how to mitigate delays. ↩

Find out how color consistency affects product quality and customer satisfaction. ↩

Discover the steps involved in the production of LED downlights and how they impact lead times. ↩

Understand the complexities of shipping and how to avoid delays in your supply chain. ↩

Get insights into manufacturing lead times and how to plan your orders accordingly. ↩