Feeling stuck choosing between OEM1 and ODM2 for your lighting products? A wrong move can cost time and money. Understanding the difference is key to making the right decision.

The best choice depends on your business strategy. OEM (Original Equipment Manufacturer) is ideal if you have a unique product design and want full control. ODM (Original Design Manufacturer) is better for getting quality products to market quickly using the factory's proven designs.

Choosing a manufacturing partner3 is one of the most important decisions you'll make. It affects your product quality4, brand reputation, and bottom line. It's more than just a simple choice; it's a strategic partnership that needs to fit your business perfectly. Let's break down the details to help you find the best path forward for your lighting projects.

Which is better, OEM or ODM?

Are you worried about picking the wrong manufacturing model? A bad choice can waste your budget and delay your launch. Let’s figure out which path is truly best for you.

Neither OEM nor ODM is universally "better." OEM is superior for creating a unique, protected product where you own the intellectual property5. ODM is better for speed, lower initial investment, and leveraging a factory's existing engineering expertise6. Your business goals7 should drive the decision.

When clients ask me whether to go with OEM or ODM, I always turn the question back to them: "What are you trying to achieve?" The answer tells me everything I need to know. OEM is the path for visionaries who have a specific, innovative downlight design in mind. They are building a brand on uniqueness and are willing to invest more upfront in tooling and development to own the design completely. This route offers the highest degree of control and brand protection.

However, many successful businesses I work with, like a purchasing manager I know named Shaz, often prefer the ODM route. They need to get reliable products8 into their market quickly to win contracts. They don't have the time or resources for a six-month R&D cycle. They trust my factory's designs, which we've spent years perfecting.

The Tooling Investment Fallacy

A common mistake I see is focusing too much on tooling. Some clients think that if they pay for the mold, they "own" the product. That's not always true. You might own the physical tool, but the factory can still own the underlying design IP. I once saw a competitor take a client's tooling investment9, make a tiny, unnoticeable change to the heatsink design, and sell a nearly identical product to someone else. The client owned a piece of metal, but they didn't own the exclusive rights to the design itself. True ownership comes from the design files and patents, which is the core of an OEM agreement. Don't let tooling costs distract you from what really matters: control over the intellectual property.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Primary Goal | Build a unique product with exclusive IP | Get a proven product to market fast |

| Design Control | Full control; you provide the design | Limited; you choose from factory designs |

| Tooling Cost | High; client typically pays for new molds | None; factory uses its existing molds |

| Time to Market | Slow (6-12 months) | Fast (1-3 months) |

| IP Ownership | You (the client) | The manufacturer |

| Ideal For | Brands focused on innovation and long-term moat | Businesses focused on speed and market entry |

What is the relationship between OEM and ODM?

Do you find the terms OEM and ODM confusing? This confusion can lead to bad deals and misaligned expectations. Let’s clear up how they relate to each other for good.

OEM and ODM are not opposites; they are two points on a manufacturing spectrum. The relationship is about collaboration. A project can start as ODM and evolve to include OEM elements, creating a hybrid model. The core relationship is always between your needs and the factory's capabilities.

In my years running a lighting factory, I've learned that very few projects are 100% pure OEM or 100% pure ODM. The reality is much more fluid. Think of it as a sliding scale of customization10 and an investment of time and money. On one end, you have pure ODM, where a client picks a downlight from my catalog and we just put their logo on the box. On the far other end, you have pure OEM, where a client comes to me with a complete set of CAD files for a revolutionary new product, and my job is simply to execute their vision perfectly.

The Rise of the 'ODM+' Model

Most of my projects live somewhere in the middle. I call this the "ODM+" or hybrid model, and it's become the most dominant way of doing business in the lighting industry. A great example is my work with Shaz, a seasoned purchasing manager from the UAE. He selected one of my best-selling ODM anti-glare downlights but needed it to meet specific requirements for a luxury hotel project. He needed a very specific 2700K CCT, a CRI of 95+, and a custom bezel color to match the hotel's interior design. We didn't create a new product from scratch (that would be OEM), but we heavily modified my existing ODM product. We sourced a specific LED chip from Citizen, used a high-end Lifud driver, and created a custom powder coating. This is the ODM+ model in action—it leverages my proven design foundation but adds a layer of client-led customization. This approach gives clients like Shaz the best of both worlds: the speed and reliability of ODM with the unique features of OEM.

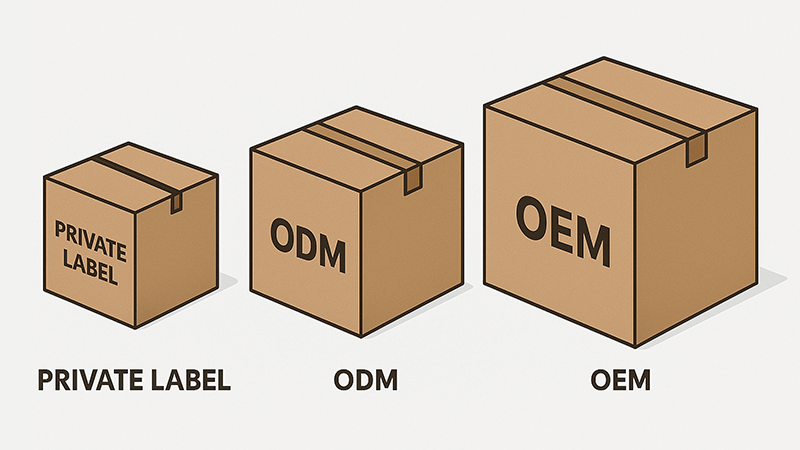

What is OEM vs ODM vs private label?

Are "private label," "OEM," and "ODM" just different words for the same thing? Misunderstanding these terms can weaken your brand. Let's define them clearly to protect your business.

Private label is putting your brand on a generic, off-the-shelf product. ODM is when a factory designs a product that you then brand. OEM is when you provide your unique design to a factory to produce exclusively for you. The difference lies in who owns the design.

Let's break these down into simple terms that I use with my clients every day. Think of it like buying a suit.

Private Label is like walking into a department store, choosing a suit off the rack, and having the store stitch their label inside. The suit is generic; many stores might sell the exact same one. It's the fastest and cheapest way to get a product, but you have no control and zero exclusivity.

ODM (Original Design Manufacturer) is like going to a tailor who has their own collection of suit designs. You choose a style you like, and they make it for you in your size and perhaps let you pick the button color. The design belongs to the tailor, but the final product is made for you with your brand on it. It’s a great balance of speed and minor customization. You are leveraging the tailor's design expertise.

OEM (Original Equipment Manufacturer) is when you hire that same tailor, but you bring your own unique design, your own fabric, and a detailed plan for exactly how you want your suit made. The tailor's job is to use their skill to bring your vision to life. The design is 100% yours, and the final suit is exclusive to you.

Leveraging Manufacturer IP

Choosing ODM or private label11 isn't a "lesser" option; it's a strategic business decision. When you choose one of my ODM downlights, you are leveraging the thousands of hours my team has spent on optical design, thermal management, and reliability testing. This is our manufacturer's IP. Instead of spending your capital on R&D, you can invest it in marketing, sales, and building your brand's reputation for quality—a reputation backed by my factory's engineering. It's a partnership where we handle the technical heavy lifting, allowing you to focus on what you do best: selling.

| Feature | Private Label | ODM | OEM |

|---|---|---|---|

| Who Designs? | The Manufacturer | The Manufacturer | You (The Client) |

| Design Basis | Generic, non-exclusive product | Factory's proprietary design | Client's proprietary design |

| Customization | Very Low (logo, packaging) | Low to Medium (colors, components) | High (complete product control) |

| IP Ownership | Manufacturer | Manufacturer | You (The Client) |

| Exclusivity | None | Negotiable, but rarely 100% | Complete Exclusivity |

What is ODM in lighting?

Considering an ODM lighting solution? You might worry about product quality and getting a generic item. Let's look at what a quality ODM partnership really means in our industry.

In lighting, ODM means a factory like mine handles the entire product creation process—from optical and thermal design to driver integration. You select a finished, proven downlight from our catalog, and we produce it with your brand. It’s the fastest way to launch a high-quality product.

When we talk about an ODM downlight at my factory, we're not talking about a simple product. We are talking about a complex system of interconnected components. This includes the aluminum heatsink designed for optimal thermal dissipation, the precision-engineered reflector or lens for the perfect beam angle, the high-performance COB LED chip, and the reliable, flicker-free driver that powers it all. As an ODM manufacturer, my team and I are responsible for making sure all these parts work together perfectly to deliver on our slogan: "Lighting Quality You Can See." We invest heavily in R&D to create these designs so that our clients don't have to.

The Critical Importance of the Bill of Materials (BOM)

However, this is where the biggest risk in ODM lies, and something I always warn new clients about. I call it the risk of "component genealogy." An unscrupulous factory might show you a beautiful sample with a top-tier Philips driver and a Cree LED chip. But when you place a bulk order, they might swap those for cheaper, no-name components to increase their profit margin. Suddenly, your failure rate skyrockets and your brand reputation is damaged.

This is why the Bill of Materials (BOM)12 is the most important document in any ODM relationship. It's a detailed list of every single component in the product. When I work with a professional buyer like Shaz, he insists on a "locked BOM." This means we agree on every component—down to the brand and model number of the driver—and that list cannot be changed without his explicit written approval. A trustworthy ODM partner will always be transparent about their BOM and welcome a supply chain audit. It's the only way to guarantee the quality you were promised is the quality you actually receive in every single shipment.

Conclusion

Choosing between OEM and ODM isn't about better or worse. It is about aligning your manufacturing strategy with your business goals, resources, and the unique brand you want to build.

Explore this link to understand how OEM can provide you with unique product designs and full control over your manufacturing process. ↩

Learn about ODM and how it can help you quickly bring quality products to market using proven designs. ↩

Find out what to consider when selecting a manufacturing partner to ensure a successful collaboration. ↩

Understand the key factors that affect product quality and how to ensure high standards in production. ↩

Discover the significance of intellectual property in protecting your unique designs and innovations. ↩

Explore how leveraging engineering expertise can enhance your product's reliability and performance. ↩

Explore strategies for aligning your manufacturing processes with your overall business objectives. ↩

Understand the characteristics of reliable products and how they contribute to customer satisfaction. ↩

Understand the implications of tooling investment and how it affects your ownership of product designs. ↩

Explore the advantages of customization and how it can enhance your product's appeal and market fit. ↩

Discover how private label differs from OEM and ODM, and its implications for brand ownership. ↩

Learn about the importance of a BOM in ensuring product quality and consistency in manufacturing. ↩