Are you tired of sorting through endless supplier quotes? A low price looks good at first, but a bad choice can damage your project and reputation. I will guide you beyond the price.

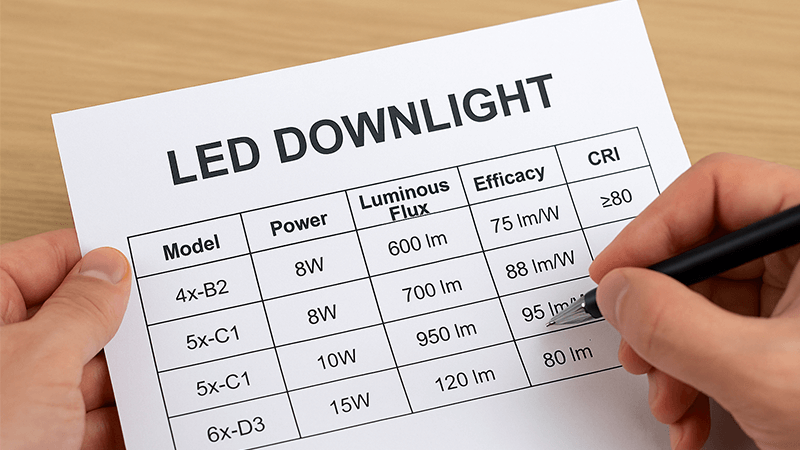

To evaluate LED downlight offers, you must look past the spec sheet. Focus on the hidden components like the driver brand, capacitor temperature rating, and housing finish. These unseen details determine a light's true lifespan and performance, representing real value far better than the initial purchase price.

That's the short answer. But I know that a professional like you needs more than just a quick tip. You need real, actionable knowledge to challenge suppliers and make genuinely informed decisions that protect your investments. Over decades in this industry, from the factory floor to running my own business, I've learned what truly matters. Let's break down exactly what to look for, so you can stop guessing and start knowing.

How to know if LED lights are good quality?

Do all new LED lights look the same to you? Trusting a datasheet full of promises is risky when a premature failure can cause huge problems. Let me show you what to check.

Look beyond the LED chip brand. The real signs of quality are in the driver's components, the heat sink's intelligent design (not just its size), and the durability of the housing's finish. A quality light is built to last in every part, not just the part in the spotlight.

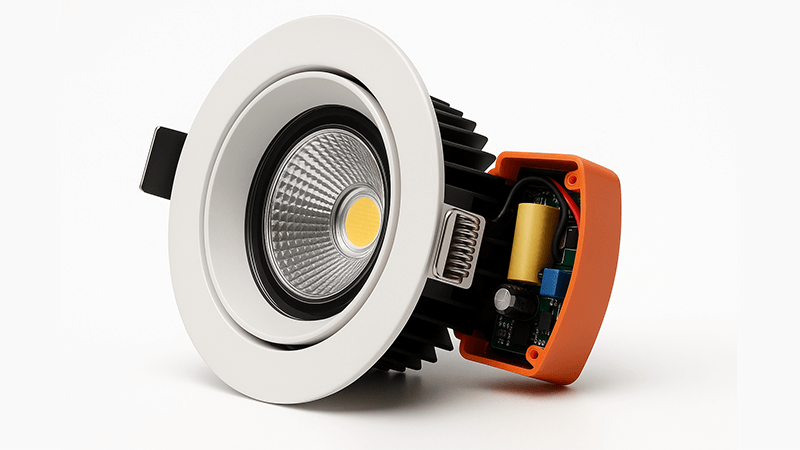

I always tell my partners that a good LED downlight is a system. It is only as strong as its weakest link. Too many people focus only on the LED chip brand1, like Cree or Philips. While important, that's just one piece of the puzzle. I have seen hundreds of failed lights in my career, and the LED chip itself is rarely the first thing to go. So, where should you look? You must dig deeper into the construction and components that suppliers often don’t mention in their bold-print marketing.

First, I always examine the housing. The finish tells a story. A cheap light often uses a simple spray paint. It looks fine at first, but it chips easily and, more importantly, can trap heat. A superior product will use an anodized or powder-coated finish. This is much more durable and helps with heat dissipation.

Next is the heat sink. Bigger isn't always better. The design is far more important. A well-designed heat sink has complex fins that maximize the surface area exposed to the air. It also has a very efficient thermal path to pull heat away from the sensitive LED chip and driver components. You can’t judge this from a picture. You must ask the supplier about their thermal management design2. A good supplier will be proud to explain it.

Finally, the most critical part is often the driver. I’ll discuss this more later, but the quality of the internal components, especially the capacitors, is a huge sign of overall product quality.

How do I choose a good LED downlight?

Choosing the right downlight can feel complex. You want performance and reliability, but you also have a budget to meet. Picking the wrong one can lead to costly replacements. I'll simplify the choice for you.

To choose a good LED downlight, start with the driver. Ask for the brand and check its specifications, especially the capacitor's temperature rating—look for 105°C. Then, verify the heat sink design3 is efficient, not just large. These technical choices guarantee a longer, more reliable service life.

When I walk a client like Shaz through a choice, I tell him to think like an engineer for a moment. Forget the marketing, and focus on the three pillars that determine 90% of a downlight's long-term performance and value.

The Driver: The Heart of the Light

The driver is the electronic power supply4 that converts AC power to the low-voltage DC power the LED needs. It is the component most likely to fail first. A cheap, poorly made driver will doom an expensive, high-quality LED chip. When I get a quote, I immediately ask: "What is the brand of the driver, and can I see its full datasheet?" Many suppliers will just say "high-quality driver5," which tells you nothing. You want to see recognized brands like Philips, Tridonic, or Osram for top-tier projects, or at least a reputable manufacturer who backs up their product.

The Thermal Management: Keeping it Cool

Heat is the number one enemy of all electronics, and LEDs are no exception. The product's lifetime is directly tied to how well it manages heat. As I mentioned, a big chunk of metal is not the same as an engineered heat sink. Look at the fins. Are they thin and numerous, or thick and simple? A good design maximizes surface area. Also, ask about the Thermal Interface Material (TIM). This is the paste or pad between the LED module and the heat sink. A cheap, low-quality TIM will dry out and fail, causing the LED to overheat and fail prematurely.

The Build and Finish: First Impressions Matter

The physical construction tells you a lot about the manufacturer's attention to detail.

| Feature | Low-Quality Indicator | High-Quality Indicator |

|---|---|---|

| Housing | Thin, flimsy metal or plastic | Sturdy die-cast aluminum |

| Finish | Simple spray paint (peels) | Anodized or powder-coated (durable) |

| Lens/Diffuser | Yellows or becomes brittle | UV-stabilized polycarbonate6 (PC) or PMMA |

| Connectors | Basic, loose-fitting | Secure, well-made plug-and-play |

Asking these specific questions forces suppliers to move beyond generic quality claims. It shows them you are an expert, and they are much less likely to offer you a low-quality product.

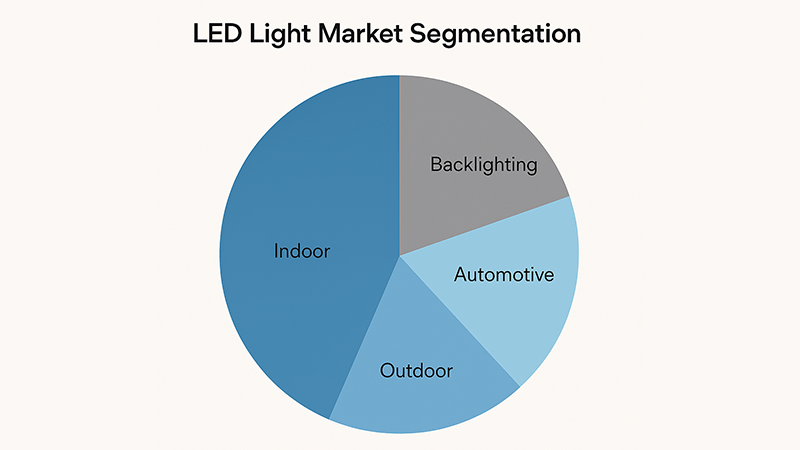

What is the market research for LED lights?

Trying to understand the huge LED market is difficult. With so many factories and price points, from high-end European brands to low-cost Asian producers, how do you find your place? It’s confusing. I can help you focus on what's important for your business.

Effective market research for LED lights means ignoring the noise. Focus on suppliers who offer transparency about their key components, like driver brands and capacitor ratings. This allows you to segment the market by true quality and reliability, not just by price or stated specifications.

When my partners ask me about market research, I tell them to simplify. The global LED market is massive, but for a professional buyer, it can be broken down into practical tiers. You don't need to know every single brand. You need to understand the types of suppliers.

Tier 1: The Global Brands

These are the household names like Philips (Signify), Osram, and GE.

- Pros: High brand recognition, extensive R&D, and generally reliable quality and support networks.

- Cons: Very high prices and less flexibility for customization or OEM projects. You are buying their brand as much as their product.

Tier 2: The Quality OEM/ODM Specialists

This is where companies like mine, iPHD, operate. We focus on manufacturing high-quality products for other brands, distributors, and large projects.

- Pros: A great balance of price and quality. High flexibility for customization (OEM/ODM). Direct access to manufacturing expertise. Transparent about components.

- Cons: Less brand recognition for the end-user. You need to do your homework to find a good partner.

Tier 3: The Mass-Market Traders and Factories

These suppliers compete almost entirely on price.

- Pros: Extremely low initial costs.

- Cons: Quality is often a mystery. They use the cheapest possible components, there is little to no transparency, and product consistency can be a major problem from one batch to the next. This tier is the source of most early-failure horror stories.

Your research shouldn't be about finding the absolute cheapest price. It should be about identifying which tier a potential supplier belongs to. As a purchasing manager, your goal is to find a reliable partner in Tier 2 who can provide a product that performs like Tier 1, but at a price that protects your margin. You do this by asking the tough questions about drivers, heat sinks, and component choices7. A Tier 3 supplier will avoid these questions, while a good Tier 2 partner will welcome them.

How many years do LED downlights last?

Suppliers promise lifespans of 50,000 hours, but you've seen lights fail in just a year. This makes it hard to trust the numbers. What really determines how long they last? I'll give you the honest answer.

The lifespan of an LED downlight depends on its weakest component, which is almost always the driver, not the LED chip. A downlight with a standard driver might last 2-3 years, while one with a high-quality driver using 105°C-rated capacitors can realistically last 7-10 years under normal use.

The 50,000-hour claim you see everywhere (which is over 5 years of being on 24/7) refers to the LED chip itself, under perfect laboratory conditions. In the real world, that number is almost meaningless. The true lifespan of the entire fixture is decided by the driver and its components, especially the electrolytic capacitor8.

The Capacitor: The Secret Point of Failure

Inside every LED driver is an electrolytic capacitor. Its job is to smooth out the electrical current. The problem is, this component hates heat. Its lifespan is cut in half for every 10°C increase in temperature. Most LED downlights operate in hot, enclosed ceiling spaces, which is the worst possible environment for a capacitor.

This is my single most important piece of advice: always ask about the capacitor.

Many low-cost factories use cheap capacitors rated for only 85°C. In a hot ceiling, the internal temperature of the driver can easily exceed this, and the capacitor will fail very quickly—sometimes in less than a year. The light dies, and you have an angry customer.

The Mark of Quality: The 105°C Capacitor

A quality manufacturer will always use a high-temperature capacitor9, rated for 105°C. This component costs more, but it is designed to withstand the heat inside a downlight fixture. It is the single biggest factor in ensuring a long and reliable life for the driver, and therefore, the entire light.

Here's how to think about it in real-world terms:

| Component Quality | Typical Lifespan (8 hours/day) | Why? |

|---|---|---|

| Low-cost driver with 85°C capacitor | 1-3 years | The capacitor degrades rapidly in the heat of a typical ceiling. |

| High-quality driver with 105°C capacitor | 7-10+ years | The capacitor is built to handle the heat, letting the driver last. |

When a supplier will not tell you the temperature rating of their capacitors, it's a major red flag. They are hiding the fact that they are using cheap components. A supplier who proudly states they use 105°C capacitors from a good brand like Rubycon or Nichicon is a partner you can trust. This one detail tells you more about the true quality and lifespan of an LED downlight than a thousand marketing promises.

Conclusion

Ultimately, choosing the right LED downlight is not about finding the lowest price. It is about understanding true value and finding a transparent manufacturing partner you can trust for the long term.

Learn about the impact of LED chip brands on the overall quality and performance of lights. ↩

Explore the importance of thermal management design for ensuring LED downlights operate efficiently. ↩

Find out how effective heat sink design can enhance the performance and lifespan of LED lights. ↩

Understanding the electronic power supply can help you choose more reliable LED downlights. ↩

Learn the characteristics of high-quality drivers that ensure better performance in LED lighting. ↩

Explore the advantages of using UV-stabilized polycarbonate for durability in LED lighting. ↩

Learn how the selection of components can significantly impact the quality of LED downlights. ↩

Explore the critical function of electrolytic capacitors in ensuring LED driver reliability. ↩

Understand the necessity of high-temperature capacitors for reliable LED downlight performance. ↩