Choosing between SMD and COB LEDs feels complicated. You need the best performance for your project, but the technical details can be a real headache. Get it wrong, and you risk your project's success.

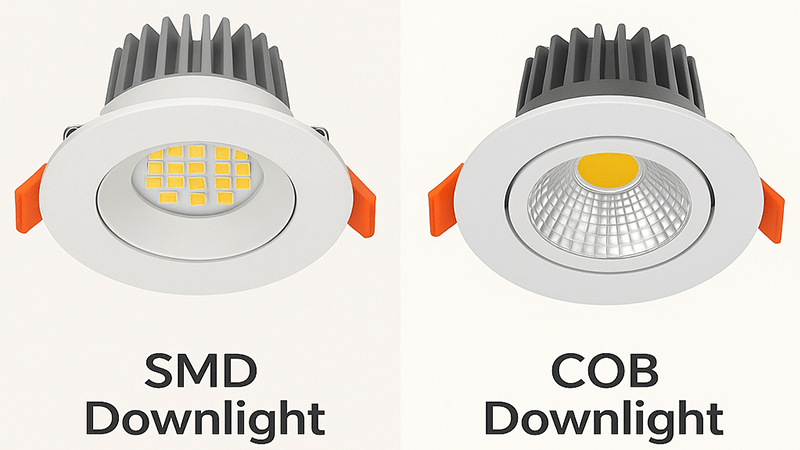

The right choice depends entirely on your project's goals. SMD (Surface Mount Device) is ideal for general lighting, offering flexibility and lower long-term maintenance risks. COB (Chip on Board) delivers intense, focused light perfect for creating dramatic accent effects, much like traditional halogen bulbs.

This technical difference seems simple on the surface. But in my years of manufacturing lights, I've seen that the most important factors are often hidden. The choice impacts everything from your supply chain1 to your long-term maintenance2 budget. To make the best decision, you need to look beyond the basic specs. Let’s dive deeper into the questions I get asked most often.

Is SMD LED better than COB LED?

The market is full of SMD products, making it seem like the default choice. This can leave you wondering if COB technology still has a place. Is SMD always the superior option?

SMD is not automatically "better" than COB. SMD excels in creating wide, even light for general illumination and benefits from a very stable supply chain. COB is superior for high-contrast accent lighting3g](https://en.wikipedia.org/wiki/Accent_lighting)%%%FOOTNOTE_REF_4%%% where a single, powerful, and focused beam is required to make an object stand out.

When I talk with purchasing managers like Shaz, one of the first things we discuss isn't lumens per watt, but risk. The biggest difference between SMD and COB isn't just how they make light. It's how they are made and supplied. This has a huge impact on your business.

The Ecosystem vs. The Array

I call the SMD supply chain an "ecosystem." Many large companies like Samsung, Nichia, and Cree all produce individual SMD chips. This creates a healthy, competitive market. If one supplier has production delays or raises prices, I can choose another supplier with a compatible chip. This flexibility is critical for keeping production on schedule and on budget. For you, this means more stable pricing and a reliable supply of finished products.

COB technology is different. It's more of an "array." A handful of companies, like Citizen or Bridgelux, dominate the market for high-quality COB chips. These chips are complex, all-in-one units. You can't just swap one brand's COB for another without completely redesigning the downlight's housing, reflector, and heat sink. I remember a client who based a huge hospitality project on a specific COB downlight. Mid-project, the COB manufacturer discontinued that exact model. It caused a massive headache, as we had to find a new solution and they had to deal with potentially mismatched lights between different floors. This is the hidden risk of COB.

| Feature | SMD (Surface Mount Device) | COB (Chip on Board) |

|---|---|---|

| Structure | Multiple individual LEDs on a PCB | A single module with many diodes |

| Supply Chain | Diverse Ecosystem (Many suppliers) | Concentrated Array (Fewer suppliers) |

| Risk Profile | Lower supply chain risk | Higher supply chain risk |

| Flexibility | Easier to swap diode suppliers | Requires luminaire redesign for changes |

What are the disadvantages of SMD LED?

You see SMD LEDs in almost everything, but are there any hidden downsides? Choosing them simply because they are common can lead to subtle but frustrating problems in your finished projects.

The main downsides of SMD LEDs are potential color inconsistencies5 and a softer, less focused beam. The light can appear less "punchy" than COB, making it unsuitable for high-impact accent lighting. Managing many individual diodes also introduces more chances for slight variations between fixtures.

For a purchasing manager responsible for large projects, consistency is everything. You expect every single light fixture you order to look and perform identically. With SMD technology, achieving this requires careful attention to detail, specifically around something we call color binning6.

Taming the MacAdam Ellipse

In LED manufacturing, we use the MacAdam ellipse7 to measure and control color consistency. A "3-step MacAdam ellipse" means the color variation between LEDs is so small that the human eye can barely see it. As a manufacturer, when I buy SMD chips, I have to specify and pay more for chips from a very tight "bin." If I don't, or if I have to use chips from different production batches for a large order, you might see slight color differences when you install the downlights side-by-side. I've seen it in large offices, where one row of lights looks just a bit warmer or cooler than the next. It's a small detail that can make a professional installation look amateur.

This places a burden on you, the buyer. You need to ensure your supplier is using tightly binned LEDs. COB chips, on the other hand, are tested and binned as a single unit. The light from one COB chip is perfectly uniform across its surface. This solves the initial consistency problem but creates a new one for long-term maintenance, which we'll discuss later.

| Consistency Challenge | SMD | COB |

|---|---|---|

| Initial Installation | Risk of variation between different fixtures | High uniformity within a single fixture |

| Color Control | Depends on the LED manufacturer's binning | Binned as a single, complete light source |

| Responsibility | Buyer must specify tight binning (e.g., 3-step) | Simpler initial specification |

| Project Impact | Can create a "checkerboard" effect on ceilings | Ensures each individual light is perfect |

What are the disadvantages of COB lighting?

The powerful, clean look of a COB downlight is very attractive. But what if one single point of failure can ruin an entire installation? This is the major hidden risk of COB.

The primary disadvantages of COB lighting are its single point of failure and challenging long-term replacement. If the chip fails, the whole light goes out. Finding an exact replacement COB model years later can be difficult or impossible, leading to high maintenance costs and inconsistent lighting.

When planning a lighting project8, you have to think about Day 1 and Year 5. COB lights look fantastic on Day 1, but they can become a maintenance nightmare by Year 5. This comes down to how they fail.

Graceful Degradation vs. Brittle Failure

I use these terms to explain long-term reliability. An SMD downlight uses many small LEDs. If one or two of those diodes fail over time, the light output drops slightly, but the fixture still works. You might not even notice it. This is "graceful degradation9." It gives maintenance teams warning and flexibility.

COB lights experience "brittle failure10." The entire fixture relies on that single COB chip. If that chip fails, the light is 100% dead. In a hotel corridor, a retail display, or a restaurant, a single dark fixture is immediately noticeable and looks terrible. It creates an urgent maintenance demand.

I worked with a hotel group that installed beautiful COB downlights throughout their properties. Three years later, a few started failing. When their purchasing manager tried to order replacements, he learned the manufacturer had discontinued that exact COB chip. They faced a terrible choice: replace all the lights in an entire corridor to ensure they matched, or live with mismatched lights from a different brand. This is a real-world problem that starts with a simple technology choice. For long-term projects, this risk must be considered. SMD provides a much safer, more manageable maintenance strategy over the life of the building.

Is COB or SMD Better for Downlight Applications?

You know you need a downlight, but choosing the engine inside feels like a huge decision. If you pick the wrong one, you could fail to create the exact mood and feeling your client wants.

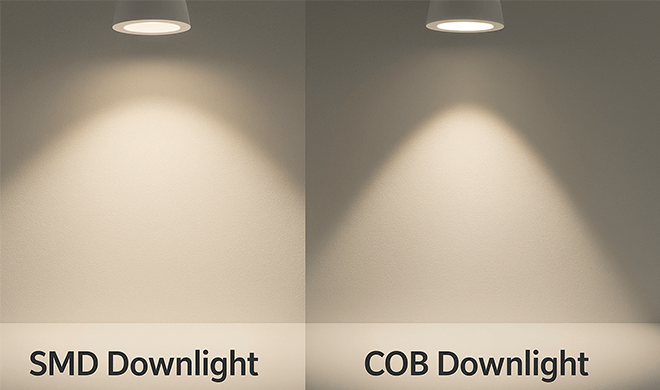

Neither is better; the best choice depends on what the downlight needs to do. For creating soft, even ambient light in offices or hallways, SMD downlights are a superior choice. For creating dramatic, high-contrast accent lighting in galleries or retail, COB downlights are better because they mimic halogen.

The most important question I ask my clients is not about the technology. It's about emotion. How do you want people to feel in this space? The answer tells me whether we should use SMD or COB.

Creating Emotion with Light

For decades, the standard for high-end lighting was the halogen bulb. Its single, glowing filament created a crisp, focused light with sharp shadows. We emotionally connect this kind of light with luxury, drama, and focus. COB technology is the true successor to halogen. Its single-point light source does the same thing: it makes objects pop. This is perfect for a gallery that needs to highlight a sculpture, a restaurant that wants to create intimate pools of light over tables, or a retail store that wants to make diamonds sparkle.

SMD downlights do the opposite. Their multiple light sources blend together to create a soft, diffuse, low-shadow light. This is perfect for functional spaces where the goal is comfort and clarity. Think of an open-plan office where you need to reduce glare on computer screens, or a classroom where students need to see clearly without harsh shadows.

As a purchasing professional, you can provide immense value by guiding your clients through this conversation. Ask them about the desired atmosphere. Do they want dramatic and focused (COB) or comfortable and even (SMD)? This moves the conversation from technical specs to project goals, which is where the best decisions are made. A gallery owner I worked with was obsessed with achieving the perfect dramatic shadow11 behind his art pieces—a feat only a COB downlight could achieve to his satisfaction.

Conclusion

SMD and COB technologies both have clear advantages. Choose SMD for flexible, low-risk general lighting12. Choose COB for dramatic, high-impact accent lighting. Understanding the trade-offs is key to success.

Gain insights into how supply chain dynamics impact the availability and cost of LED products. ↩

Find out the key factors that influence the maintenance and longevity of LED lighting solutions. ↩

Learn how to create high-contrast accent lighting for dramatic effects in various settings. ↩

Discover how accent lighting enhances the visual appeal of spaces by highlighting specific features. ↩

Explore the reasons behind color inconsistencies and how to mitigate them in lighting projects. ↩

Understand the process of color binning and its importance for achieving uniform lighting. ↩

Learn about the MacAdam ellipse and its significance in ensuring color consistency in LEDs. ↩

Discover essential factors to consider when planning and executing a lighting project. ↩

Understand the concept of graceful degradation and its advantages for long-term lighting performance. ↩

Discover the implications of brittle failure in COB lighting and its impact on maintenance. ↩

Learn techniques for using lighting to create dramatic shadows that enhance art presentations. ↩

Understand the role of general lighting in creating a comfortable and functional environment. ↩