Struggling to pick the right LED downlight1 from a sea of options? Choosing the wrong one can waste money, create a poor lighting effect, and ruin your project's design.

The main types of LED downlights are defined by their installation method (recessed, surface-mounted), light source (SMD, COB), and specific features like IP rating (IP20 for indoor, IP65 for wet areas) or adjustability. Understanding these key differences is crucial for selecting the perfect fixture for your specific needs.

Choosing the right downlight goes far beyond just picking a model from a catalog. As a manufacturer for over a decade, I've seen firsthand how a seemingly small detail can make or break an entire project. I remember a conversation with Shaz Mahamood, a seasoned purchasing manager from the UAE. He was sourcing for a new luxury hotel and needed to understand every nuance, from the type of LED chip used to the specific IP rating2 required for the spa and pool areas. For him, getting it right meant a satisfied client, a stunning final result, and a long-term business relationship. Getting it wrong was simply not an option. This is why a deep dive into the details is not just helpful, it's essential. Let's break down the most common questions I hear every day.

What are the three types of LED lights?

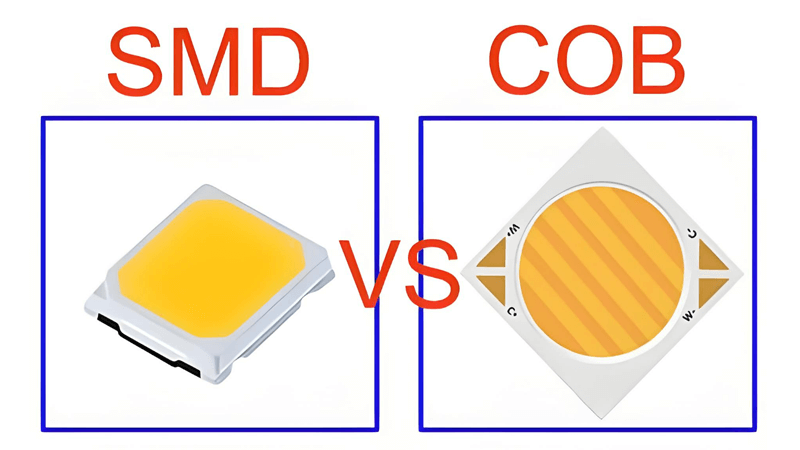

Are you feeling overwhelmed by technical acronyms like SMD3 and COB4? This common confusion can easily lead you to choose a light source that looks cheap or fails to create the desired ambiance for your space.

The three main types of LED packages you'll encounter in downlights are SMD (Surface Mounted Device), COB (Chip on Board), and MCOB (Multi-Chip on Board). SMD uses many small, distinct LEDs, while COB groups them into one single, powerful, and uniform light source.

When I first entered the lighting industry, everything was built around SMD LEDs. They were revolutionary. But as designers and architects started using them more, a common complaint emerged. An SMD downlight uses a board peppered with many individual light-emitting diodes. When you look at the fixture, you see all these tiny points of light, which can create a busy, distracting look and produce multiple, sharp-edged shadows. The market demanded something cleaner. The evolution to COB technology wasn't just about a quest for more brightness; it was a response to this aesthetic demand5. We call the goal "Optical Quietness." A COB downlight integrates multiple LED chips onto a single substrate, covered by a uniform layer of phosphor. The result is a single, clean point of light that looks far more professional and soothing to the eye. This perfectly mimics the classic, single-beam appearance of the halogen bulbs that architects and designers have loved for decades. It was a true game-changer for high-end residential and commercial projects where the quality and feel of the light are just as important as the quantity.

| Feature | SMD (Surface Mounted Device) | COB (Chip on Board) |

|---|---|---|

| Visual Appearance | Multiple small points of light visible. | A single, uniform, and homogenous light source. |

| Light Quality | Can create multiple shadows and potential glare. | Softer, single shadow, providing better visual comfort. |

| Typical Use Case | LED strips, bulbs, panel lights. | High-quality architectural downlights, spotlights. |

| Heat Management | Heat is spread over a larger circuit board. | Heat is highly concentrated, requiring a superior heatsink. |

| Optical Design | Requires complex reflectors or lenses to blend light points. | Simpler optics design; works well with a single reflector. |

What is the difference between IP20 and IP65 downlight?

Are you worried about which downlight to specify for a bathroom, kitchen, or a covered outdoor patio? Installing a fixture with an incorrect IP rating is not only a rookie mistake but a serious safety hazard that guarantees premature failure and potential liability.

IP20 downlights are designed exclusively for dry, indoor locations, offering basic protection against solid objects but none from water. In contrast, IP65 downlights are fully dust-tight and protected against water jets, making them safe and durable for bathrooms, kitchens, and covered outdoor areas.

Many specifiers see an IP656 rating on a data sheet and just tick the box. As a manufacturer, I see it as a significant thermal challenge. To achieve an IP65 rating, you must completely seal the fixture with gaskets and adhesives to prevent any ingress of dust or water. But in doing so, you create an oven. You trap all the heat generated by the LED chip and the driver inside a small enclosure. Heat is the absolute number one enemy of LED performance and longevity. A poorly designed IP65 downlight will literally cook itself to death. The true mark of a superior IP65 fixture isn't just its seal, but its ability to efficiently manage heat despite being sealed. When my team at iPHD engineers an IP65 downlight, our primary focus is on advanced thermal management7. This involves using high-grade ADC12 die-cast aluminum for the heatsink, designing optimal fin structures to maximize surface area, and ensuring a direct thermal pathway from the LED chip to the outside of the fixture. I have dissected countless cheap IP65 lights that failed in under a year, and the culprit is always the same: an undersized heatsink and no thought given to thermal design.

| Rating | Protection vs. Solids (1st Digit) | Protection vs. Liquids (2nd Digit) | Recommended Environment |

|---|---|---|---|

| IP20 | 2: Protected from objects >12.5mm (e.g., fingers). | 0: No protection against water. | Living rooms, bedrooms, offices, hallways. |

| IP44 | 4: Protected from objects >1mm (e.g., wires). | 4: Protected from water splashes from any direction. | Bathroom Zone 2 (away from direct spray). |

| IP65 | 6: Totally protected from dust ingress. | 5: Protected from low-pressure water jets from any direction. | Bathrooms (including inside showers), kitchens, outdoor soffits. |

What is the difference between LED downlight and recessed light?

Are you using the terms "downlight" and "recessed light8" interchangeably? While common, this can cause significant confusion when specifying products with suppliers or discussing project requirements with clients, leading to costly misunderstandings.

A "recessed light" is a broad category for any fixture installed into a hollow opening in a ceiling. A "downlight" is a specific type of recessed light that is designed to cast its light directly downwards. Therefore, while all downlights are recessed lights, not all recessed lights are downlights (e.g., wall washers, adjustable accent lights).

This distinction in terminology might seem minor, but it reveals a fundamental split in market philosophy and product design. When I hear a contractor ask for a basic "recessed light," they are often referring to the modern, ultra-thin "wafer" or "canless" style lights. These are all-in-one, disposable fixtures where the LED, driver, and housing are a single, sealed unit. Their main advantages are low cost and simple installation. The major disadvantage is that if any part fails, you must remove and discard the entire fixture. When a professional like Shaz, the UAE purchaser, specifies a "downlighting system," he has a completely different mindset. He's thinking about long-term value and serviceability. This system is modular, consisting of a separate housing (the "can" installed in the ceiling), a replaceable LED light engine, and an interchangeable trim. This architectural approach offers huge benefits for commercial projects. If an LED module fails five years from now, maintenance can swap it in minutes without damaging the ceiling. If the client wants to upgrade to a newer, more efficient technology in the future, it's a simple module swap. It's the difference between buying a disposable product versus investing in a lasting, flexible lighting infrastructure.

| Term | Component Structure | Philosophy & Use Case | Serviceability |

|---|---|---|---|

| Recessed Light (Commonly disposable wafer type) | All-in-one unit with integrated LED, driver, and trim. | Low initial cost, fast installation, "fit and forget." Suited for budget-conscious or residential projects. | Low. The entire unit must be replaced upon failure. |

| Downlight (As a serviceable system) | Modular: Separate housing, replaceable LED module, and interchangeable trim. | Higher initial investment, designed for longevity, flexibility, and future-proofing. The standard for commercial and high-end projects. | High. Individual components can be easily replaced or upgraded. |

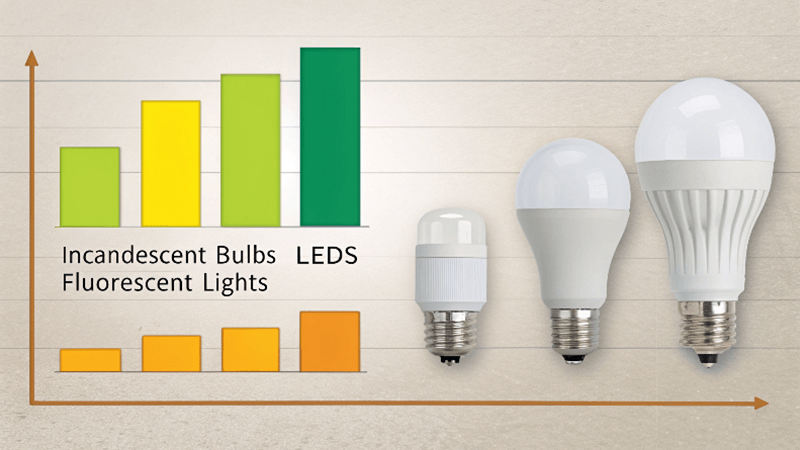

Which LED type is the brightest?

Are you still asking suppliers for the "brightest" LED downlight you can find? This is one of the most common mistakes I see. Focusing only on brightness is a flawed approach that often leads to poor light quality, visual discomfort, and unnecessarily high energy bills9.

Asking which LED is "brightest" is the wrong question. Professionals focus on Luminous Efficacy (measured in lumens per watt), which indicates efficiency. A high-quality LED produces a large amount of light (lumens) while consuming very little energy (watts), all while maintaining excellent light quality.

Inside a lighting factory, the contest for the "brightest" LED is an amateur's game. Any engineer can make an LED brighter by simply pushing more power (watts) through the chip. The problem is that this drastically increases heat, shortens the lifespan, and often ruins the quality of the light. The real battleground, where true engineering expertise and quality manufacturing shine, is in achieving the highest Luminous Efficacy (lm/W) at a specific Color Rendering Index10 (CRI) and with superior color consistency. It’s easy to find a very bright LED with a low CRI of 70. But under that light, colors will look dull, skin tones will look unnatural, and products will look lifeless. The true challenge is delivering over 100 lm/W while also maintaining a beautiful, accurate CRI of 90+ and guaranteeing tight color consistency across an entire batch. For a large project, consistency is critical. You cannot have one downlight in a hotel corridor appearing slightly yellow and the one next to it looking pinkish. This is where the MacAdam Ellipse11 (or SDCM) rating comes in. A rating of <3 SDCM is invisible to the human eye, ensuring perfect uniformity. So the right question isn't "How bright is it?" but rather, "How efficient is it, how good is the color rendering, and how consistent is it?"

| Metric | What it Measures | Why it Matters More Than "Brightness" | Professional Standard |

|---|---|---|---|

| Lumens (lm) | The raw amount of visible light output. | Measures quantity, but says nothing about efficiency or quality. | Varies by application. |

| Luminous Efficacy (lm/W) | How many lumens are produced for each watt of energy consumed. | This is the true measure of efficiency. Higher is better, meaning lower energy bills and less heat. | >90 lm/W |

| CRI (Color Rendering Index) | How accurately the light reveals the true colors of objects, on a scale of 0-100. | Determines if spaces look vibrant and natural or dull and washed out. | CRI >90 (Excellent) |

| SDCM (Color Consistency) | How much variation in color exists between different light fixtures in a batch. | Ensures all lights in an installation look identical, preventing a "patchwork" effect. | <3 ellipses (No visible difference) |

Conclusion

Ultimately, choosing the right LED downlight requires moving beyond surface-level questions. It's about understanding the nuances of technology, application-specific needs, and the key metrics of quality and performance for long-term success.

Explore this link to understand the fundamentals of LED downlights and their applications. ↩

Understanding IP ratings is crucial for selecting the right downlight for specific environments. ↩

Learn about SMD technology and its advantages in LED lighting for better decision-making. ↩

Discover the benefits of COB technology and how it enhances lighting quality. ↩

Explore how aesthetic demand influences lighting technology and design choices. ↩

Explore the features of IP65 downlights and their suitability for wet areas. ↩

Explore the significance of thermal management for LED longevity and performance. ↩

Clarify the terminology and understand the distinctions between these lighting types. ↩

Discover how efficient LED lighting can lead to significant savings on energy costs. ↩

Understand CRI and its importance in achieving accurate color representation. ↩

Understand the MacAdam Ellipse and its role in ensuring color consistency. ↩