Are you trying to decide between SMD and COB for your project? The wrong choice can lead to poor lighting, high costs, and unhappy clients. Let me help you understand.

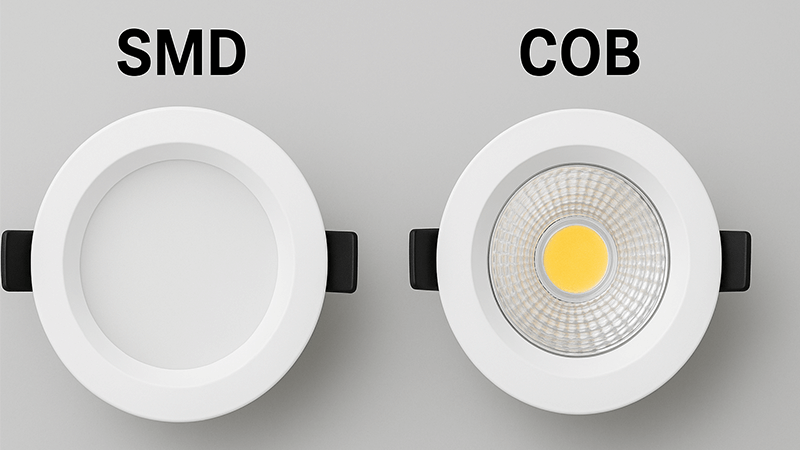

The main difference is how they deliver light. SMD (Surface Mounted Device) uses many small LED chips for wide, soft light. COB (Chip on Board) uses a single, dense cluster of chips for a powerful, focused beam. It's a choice between ambient floodlight and a sharp spotlight.

But the distinction goes far beyond just the look of the light. The technology you choose impacts everything from thermal management1 and cost to the final architectural feel2 of a space.

Let's dive into the questions I hear most from purchasing managers. Answering these will give you the confidence to select the right technology for any application, ensuring both quality and value for your projects.

What is the lifespan of a COB light?

Worried your COB lights will fail early? A short lifespan means high replacement costs and calls from frustrated clients, a risk that can damage your budget and your professional reputation.

A well-made COB light with excellent thermal management will last 30,000 to 50,000 hours. The lifespan is not determined by the chip itself, but by the quality of the heatsink and driver. Poor heat dissipation is the number one reason for premature failure.

The biggest challenge with COB technology is heat. Because all the light-emitting diodes are packed into a tiny area, they generate a very dense point of heat. This creates what I call the thermal management paradox. COB is very efficient at turning electricity into light, but it creates a massive challenge in getting rid of the waste heat. The entire system—especially the heatsink3—must be designed to draw that heat away effectively.

I remember a client who bought cheap COB downlights for a hotel lobby. They looked great at first. But the manufacturer saved money on the heatsink. Within a year, over 30% of the lights had dimmed or failed completely. It taught a valuable lesson: the quality of a COB downlight isn't in the chip; it's in the heatsink behind it.

| Feature | COB (Chip on Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Heat Generation | Highly concentrated in one small spot | Spread out across a larger circuit board |

| Heatsink Needs | Absolutely critical; requires a large, well-designed heatsink | Less critical; the heat is less dense |

| Lifespan Factor | Directly tied to the heatsink's quality and size | More forgiving of average thermal design |

| Common Failure | Overheating damages the chip directly | Can be chip failure or solder joint failure |

Is COB Better Than SMD for Downlights?

Are you struggling to decide which technology is "better"? Choosing the wrong one can create uncomfortable glare4 in one room or dull, uninspired lighting in another. This choice defines the atmosphere.

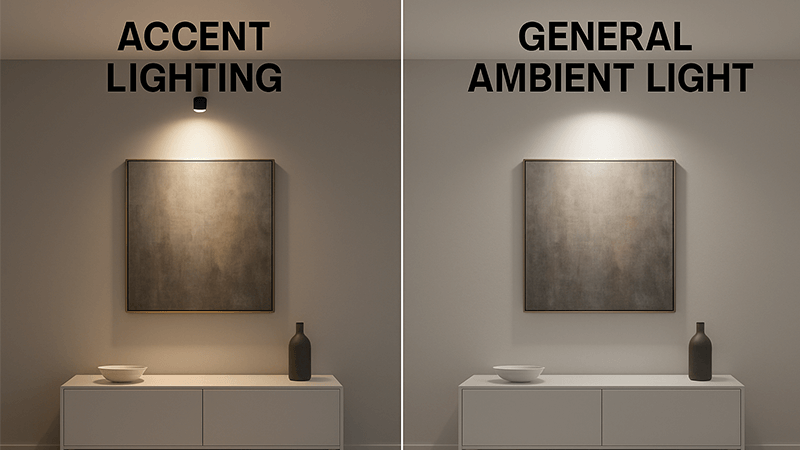

Neither is universally better; they serve different purposes. COB excels at creating focused, high-contrast light, making it perfect for accent lighting. SMD is better for providing wide, even, and comfortable light, which is ideal for general ambient illumination. The best choice depends on the desired effect.

This choice is really about your lighting philosophy5. It’s not just a technical specification, but an architectural decision. Do you want to paint with sharp beams of light, or do you want to fill a space with soft, comfortable brightness?

COB acts like a single point of light. This makes it very easy to control with reflectors and lenses to create a sharp, focused beam. Think of a spotlight in a theatre or museum. It’s for creating drama and highlighting features.

SMD, with its many small light sources, naturally creates a more diffuse, softer light. It's harder to get a tight beam from an SMD source, but it's fantastic for general lighting where you want to minimize shadows and glare. I worked with a designer for a high-end retail store. We used COB downlights to create dramatic pools of light only on the merchandise, making the products look like jewels. That's using optical control as a design tool.

| Lighting Goal | Best Choice | Why? | Example Application |

|---|---|---|---|

| Dramatic Accent Lighting | COB | Its single point source is easy to focus. | Highlighting artwork, retail displays, architectural details. |

| General Ambient Light | SMD | Multiple light points create soft, even, low-glare light. | Offices, hallways, kitchens, living areas. |

| High-Intensity Punch | COB | High lumen density creates a powerful beam. | Warehouses, auditoriums, high-ceiling lobbies. |

| Visual Comfort | SMD | The light source is spread out, reducing glare. | Task lighting areas, conference rooms, schools. |

Do COB lights consume more electricity?

Are you worried about the energy bill? You might look at COB's intense beam and assume it uses more power than a standard SMD light. Overlooking this could impact the project's long-term operating costs.

No, not really. Both COB and SMD technologies have very similar energy efficiency, measured in lumens per watt. A 10-watt COB downlight and a 10-watt SMD downlight consume the same amount of electricity. The only difference is how that light is delivered to the room.

Many purchasing managers fall for the myth of component cost6. They see a COB chip and think it's just one piece. They don't consider the total system cost, which is what truly matters for your budget and the product's performance.

While the energy consumption is similar, the cost to build a quality fixture can be very different. A COB system requires a simpler circuit board but demands a much larger, more expensive heatsink to handle the concentrated heat. An SMD system needs a more complex circuit board and more assembly steps, but its heatsink can be much smaller and cheaper. I once had a client show me a quote for a very cheap COB downlight. I opened it up and showed him the tiny, flimsy heatsink. He saved a dollar on the fixture but was buying a product that would only last a fraction of its advertised life. It’s the total cost of ownership7, including replacement, that matters.

| Component | COB System | SMD System | The Impact on Cost |

|---|---|---|---|

| LED Source | A single, more powerful chip | Many smaller, cheaper chips | Total chip cost is often similar. |

| Circuit Board (PCB) | Simpler and smaller | Larger and more complex | SMD boards cost more to make. |

| Thermal Management | Very expensive, robust heatsink required | Cheaper, simpler heatsink is sufficient | This is the key cost driver for COB. |

| Total System Cost | Driven by the need for a quality heatsink. | Driven by PCB and assembly complexity. | A quality product from either type will be priced similarly. |

What are the disadvantages of COB?

Are you considering COB but worried about the downsides? Every technology has trade-offs. Ignoring them can lead to problems with glare, color inconsistency, and difficult repairs in the field.

The main disadvantages of COB are its intense glare if not properly shielded, its heavy reliance on a perfect thermal system, and its lack of flexibility. If a single part of the chip fails, the entire unit must be replaced, and you can't create complex color patterns.

Let's break down the real-world disadvantages. Besides the critical need for a great heatsink, the biggest issue is glare. That single point of light is incredibly bright and can be uncomfortable without deep baffles or frosted lenses. Also, COB is not flexible. An SMD board can have chips of different colors for tunable white light, but a COB is one solid unit.

A common myth I need to address is color consistency8. Some believe COB is inherently more consistent. This is false. Color consistency is a result of manufacturing discipline, not technology type. It comes from "binning," where LED chip makers sort chips by exact color. As a lighting manufacturer, we choose whether to buy chips from a very tight, expensive bin or a cheap, wide one. A cheap manufacturer will use poorly-binned chips for both their SMD and COB products, resulting in lights that don't match. The technology doesn't guarantee consistency; your supplier's commitment to quality does.

| Disadvantage | Description for COB Technology | How to Overcome It |

|---|---|---|

| Glare | The intense, single point of light can be harsh on the eyes. | Always use fixtures with deep-set optics, baffles, or quality lenses. |

| Heat Point | All heat is focused on one tiny spot, making failure catastrophic. | Never compromise on heatsink quality. This is the most crucial part. |

| Repair | If one diode on the chip fails, the whole module is useless. | Work with a reputable supplier that has low failure rates and a good warranty. |

| Color Shift | Can have color differences between units if from a poor supplier. | Ask your supplier for their MacAdam ellipse data. Ensure they use tight 3-step binning or better. |

Conclusion

Choosing between SMD and COB isn't about which is better, but which is right for your goal. Focus on the lighting effect, total system quality, and your manufacturer's discipline.

Discover the critical role of thermal management in ensuring the longevity and performance of LED lights. ↩

Discover how different lighting technologies can enhance or detract from architectural aesthetics. ↩

Understand how heatsinks affect the performance and reliability of COB lights. ↩

Learn about glare issues in COB lighting and how to mitigate them for better user comfort. ↩

Explore the concept of lighting philosophy and how it influences design choices. ↩

Understand the factors that affect component costs to make better purchasing decisions. ↩

Explore how total cost of ownership impacts your lighting project budget and long-term planning. ↩

Discover the importance of color consistency in lighting and how it affects design outcomes. ↩