Struggling to keep up with lighting innovations1? Sourcing outdated products can hurt your projects and your reputation. Understanding the newest COB LED2 tech gives you a clear competitive advantage.

The biggest innovation is the shift from downlights as simple fixtures to fully integrated light systems. This means the COB chip, driver, optics, and housing are a single, factory-calibrated unit. This delivers unmatched performance, reliability, and superior thermal management right out of the box.

I’ve spent my entire career in the LED lighting industry. I've seen technologies come and go. But what's happening with Chip-on-Board (COB) downlights right now is truly a game-changer. It’s more than just a brighter chip or a smaller size. The entire philosophy of how we make and use these lights is changing. Let's break down what these innovations mean for you and your projects, so you can make smarter purchasing decisions.

What is the newest most efficient lighting technology?

Choosing the most efficient lighting feels overwhelming with so many options. Picking the wrong one wastes energy, increases long-term costs for your clients, and can make your bid less competitive.

While LED is the dominant platform, the most efficient applications today come from advances in Chip-on-Board (COB) technology. For commercial downlighting, high-efficacy COB LEDs3 provide the best balance of luminous efficacy4, cost, and reliability, pushing the boundaries of what's possible with lighting.

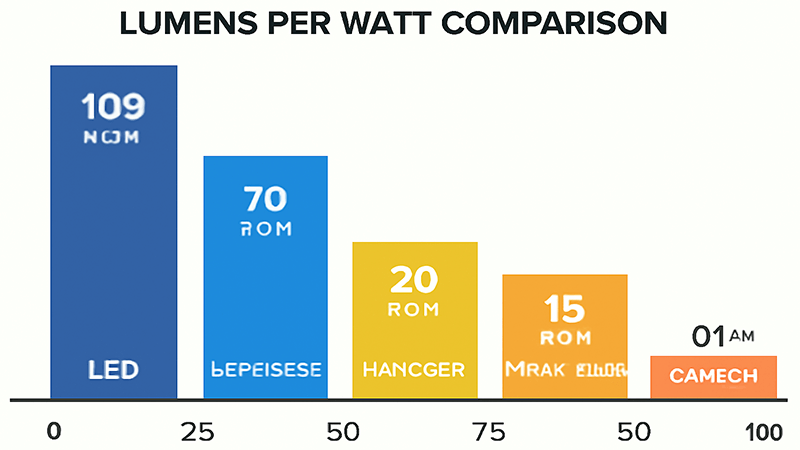

When we talk about efficiency, we are really talking about "luminous efficacy," or how many lumens of light we get for each watt of power we use (lm/W). This is the key metric you should look at. Years ago, getting 80 lm/W from an LED was considered great. Today, the game has completely changed, especially with COB technology.

From Good to Great: The Leap in Efficacy

Early LEDs were a huge step up from halogen or fluorescent lights. But the innovation didn't stop. The newest generation of COB chips has seen a massive leap in performance. We are now consistently seeing COB downlights5 that deliver between 130 lm/W to over 170 lm/W. For a purchasing manager like yourself, Shaz, this is critical information. A higher efficacy number means your client gets the same amount of light for significantly less electricity. This translates directly into lower operating costs and a faster return on investment for any project. I remember a project for a retail chain in the UAE. They wanted to upgrade their lighting but had a strict energy budget6. By using our latest high-efficacy COB downlights, they not only met their lighting requirements but also cut their lighting energy bill by over 50%.

Why COB Wins for Downlights

You also see SMD (Surface Mount Device) LEDs everywhere. So why is COB often more efficient in a downlight application? It comes down to thermal management7 and optical efficiency. A COB chip is essentially many small LEDs packed tightly onto a single ceramic substrate. This dense array allows heat to be drawn away more effectively through the heatsink. Better heat management means the LEDs run cooler, and cooler LEDs are more efficient and last longer. Furthermore, the single light-emitting surface of a COB makes it easier to control the light with a single, highly efficient reflector or lens. With SMDs, you often have more optical losses trying to direct the light from many different points.

Here is a simple comparison:

| Technology | Luminous Efficacy (lm/W) | Average Lifespan (Hours) | Heat Management |

|---|---|---|---|

| High-Efficacy COB LED | 130 - 170+ | 50,000+ | Excellent |

| Standard SMD LED | 100 - 140 | 30,000 - 50,000 | Good |

| CFL (Compact Fluorescent) | 60 - 80 | 8,000 - 12,000 | Fair |

| Halogen | 15 - 25 | 2,000 - 4,000 | Poor |

For any project where performance and energy savings8 are key, high-efficacy COB technology is the clear leader today. It’s what we build our reputation on at iPHD.

What is the next lighting technology9 after LED?

As a professional, you're always focused on the future. Sticking with today's technology is safe, but falling behind the next big thing is a serious business risk.

While today's LED technology will be the standard for many years, the next evolutions are MicroLED10 and Quantum Dot (QD) LEDs11. These promise even higher efficiency and unprecedented color quality. However, they are currently in development or used only in specialized display applications.

I get asked this question a lot. After being in a factory and watching the LED revolution happen firsthand, it's natural to wonder what's next. While the current generation of COB LED2s is fantastic, engineers and scientists are always pushing for what's next. The two most promising technologies on the horizon are MicroLED10s and Quantum Dots.

MicroLEDs: Powerful and Tiny

Imagine an LED chip the size of a grain of sand, or even smaller. Now imagine millions of them working together. That is the basic idea behind MicroLEDs. Because they are so small, they can be arranged in new ways, potentially turning entire surfaces like walls or ceilings into light sources. They are also incredibly efficient and can produce very bright light from a tiny point. The main challenge right now is manufacturing cost. Making and placing millions of these tiny LEDs with perfect precision is extremely difficult and expensive. For now, you see them in ultra-high-end video walls, but their potential for general lighting is huge. We are probably 5-10 years away from seeing them become common in commercial buildings.

Quantum Dots: Perfecting Color

Quantum Dots (QDs) are not light sources themselves. They are microscopic semiconductor crystals that absorb light of one color and emit light of another, very specific, color. When you pair them with a blue LED, you can create incredibly pure white light with a near-perfect color spectrum. This technology is already used in high-end QLED TVs to produce vibrant colors. For architectural and commercial lighting, this could be a game-changer. Imagine retail lighting that renders the color of fabrics or produce perfectly, or museum lighting that shows artwork exactly as the artist intended. The technology is getting cheaper, and we are starting to see it integrated into LED products. This is less of a replacement for LED and more of an enhancement that will bring unparalleled light quality.

Here’s a look at the timeline and applications:

| Technology | Current Status | Primary Application | Potential for General Lighting |

|---|---|---|---|

| COB LED | Mature, Mainstream | General & Commercial Lighting | Current standard |

| MicroLED | Emerging, High-Cost | High-End Displays | High (5-10 years) |

| Quantum Dot (QD) | Growing | Displays, Specialty Lighting | High (2-5 years) |

For your work today and for projects in the next few years, high-quality COB LED remains the best choice. But it is smart to keep an eye on these developments. At iPHD, we are always testing and prototyping with these next-generation components so that when they are ready for the market, so are we.

Are COB LEDs waterproof?

You're purchasing for projects in a variety of environments. You need to know if a component can handle moisture, humidity, or even direct water contact. This detail is absolutely critical.

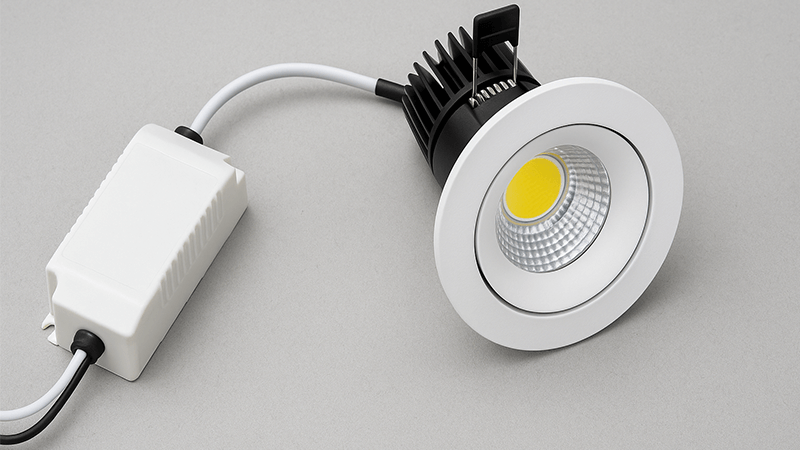

A bare COB LED chip itself is not waterproof and is very sensitive to moisture. However, the complete downlight fixture12 can be made waterproof or water-resistant by sealing it within a properly designed housing with an appropriate IP (Ingress Protection) rating.

This is an excellent question and one that highlights a common point of confusion. The magic of a COB LED is in the chip, but the performance and durability of the final product depend entirely on the fixture that houses it. A COB chip is a delicate electronic component. If water or even humidity reaches it, it will fail quickly.

The Role of the IP Rating

When you need a downlight for a bathroom, a kitchen, an outdoor soffit, or an industrial facility, you need to look for its IP rating13. IP stands for Ingress Protection. It's a two-digit code that tells you how well the fixture is sealed against solids (like dust) and liquids (like water).

- The first digit (0-6) rates protection against solid objects.

- The second digit (0-9) rates protection against water.

For a purchasing manager, understanding this code is non-negotiable. I once had a client who installed standard IP20 downlights in a high-humidity spa area. They all failed within six months. We replaced them with IP65-rated sealed units, and those have been working perfectly for years. That was a costly lesson for them, but it highlights the importance of matching the IP rating to the environment.

What IP Rating Do You Need?

The right rating depends on the specific application. A higher number means more protection.

| IP Rating | Protection Level | Common Application Examples |

|---|---|---|

| IP20 | Protected against objects >12.5mm. No water protection. | General indoor spaces like offices, living rooms, dry retail areas. |

| IP44 | Protected against objects >1mm. Protected against water splashes from any direction. | Kitchens, zone 2 in bathrooms (away from direct spray), covered outdoor areas. |

| IP65 | Totally protected against dust. Protected against low-pressure water jets from any direction. | Bathrooms (including in showers), food processing areas, outdoor soffits. |

| IP67 | Totally protected against dust. Protected against immersion in water up to 1m deep. | Outdoor ground lights, areas with potential for temporary flooding. |

So, to answer the question directly: a COB LED is not waterproof. A COB LED downlight can be. When you are sourcing, ignore any claims about the chip itself and focus only on the certified IP rating of the complete fixture. At iPHD, we take this very seriously, and all our products are rigorously tested to ensure they meet or exceed their stated IP ratings. It’s part of our commitment to quality you can see, and reliability you can count on.

Do COB lights need a special driver?

You need to ensure all components of a lighting system are compatible. A mismatch between the light source and its power supply can lead to poor performance, flickering, or complete failure.

Yes, absolutely. COB LEDs require a specialized constant current LED driver14. This driver regulates the electrical current delivered to the COB chip, ensuring stable performance, protecting it from damage, and enabling features like dimming. You cannot connect a COB chip directly to mains voltage.

This is one of the most critical technical aspects of working with LED lighting. The LED driver is the heart of the system. It's just as important as the LED chip itself. Thinking of it as just a power supply is a mistake. It is a precise electronic device designed to meet the specific needs of the LED.

Constant Current vs. Constant Voltage

Most electronic devices you are familiar with, like a laptop, use a constant voltage power supply. They need a steady 19 volts, for example. LEDs are different. They are current-driven devices. Their light output and lifespan are directly related to the forward current (measured in milliamps, mA) that flows through them. A constant current driver ensures that the COB chip always receives the exact current it was designed for, say 350mA or 700mA, regardless of small fluctuations in the input voltage. If you were to connect a COB to a constant voltage source, the current could run away, causing the chip to overheat and burn out very quickly. I've seen it happen in my factory's testing lab. An engineer accidentally used the wrong type of driver, and a brand new, expensive COB chip was destroyed in seconds.

Matching the Driver to the COB

When sourcing COB downlights, the driver is part of the integrated system I mentioned at the beginning. As a manufacturer, we carefully match the driver to the COB chip's specific requirements. Here's what we look for:

- Output Current (mA): This must match the COB's specified forward current.

- Forward Voltage (Vf) Range: The driver's output voltage range must include the COB's forward voltage.

- Power (Watts): The driver's wattage must be sufficient for the COB.

- Dimming Protocol: If dimming is required, the driver must be compatible (e.g., TRIAC, 0-10V, DALI).

Here is a simplified table to show the relationship:

| COB Specification | Required Driver Match | Result of Mismatch |

|---|---|---|

| Forward Current: 700mA | Driver Output Current must be 700mA. | Too low: Dim light. Too high: Overheating, short lifespan, failure. |

| Forward Voltage: 36V | Driver Output Voltage Range must cover 36V (e.g., 30-42V). | Range too low: Light won't turn on. Range too high: Inefficient operation. |

| Power: ~25W | Driver must be rated for at least 25W. | Driver too weak: Flickering, driver failure. |

The key takeaway for you, Shaz, is that you shouldn't have to worry about this matching process. When you buy a complete COB downlight from a reputable manufacturer like iPHD, this engineering work is already done for you. The product is a tested, matched, and certified system. This is the ultimate innovation: the luminaire is no longer a container for a replaceable part. It is a single, highly-tuned instrument for producing high-quality light.

Conclusion

The latest COB innovations have transformed downlights into integrated systems, delivering superior efficiency, reliability, and quality. Understanding these advancements ensures you source the best products for your projects.

Stay informed about the newest innovations in LED lighting technology. ↩

Explore the advantages of COB LED technology for efficient lighting solutions. ↩

Discover how high-efficacy COB LEDs can enhance your lighting projects. ↩

Learn about luminous efficacy and its importance in choosing lighting solutions. ↩

Discover the benefits of COB downlights for efficient lighting solutions. ↩

Get tips on effectively managing energy budgets for lighting solutions. ↩

Understand the role of thermal management in maximizing LED efficiency. ↩

Explore how LED lighting can significantly reduce energy costs. ↩

Stay updated on the latest innovations in lighting technology. ↩

Find out how MicroLED technology is revolutionizing lighting and displays. ↩

Explore the potential of Quantum Dot LEDs for superior color quality in lighting. ↩

Get insights on selecting the right downlight fixture for your projects. ↩

Learn about IP ratings and their significance in selecting durable lighting. ↩

Discover the importance of constant current LED drivers for COB LEDs. ↩