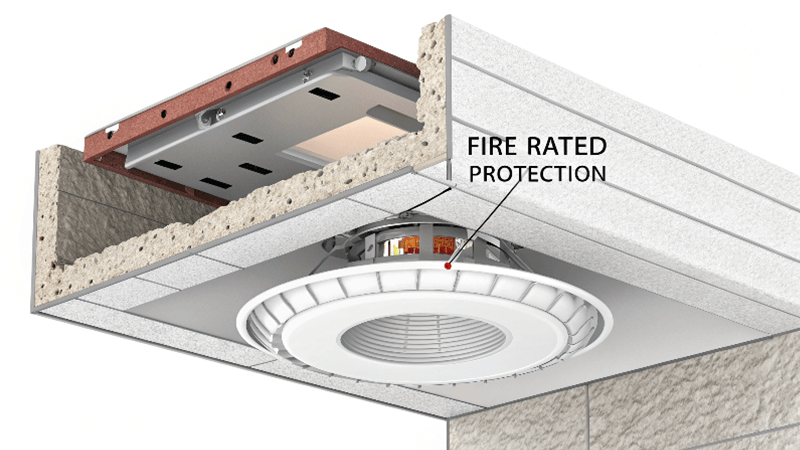

Feeling anxious about the fire risk from ceiling lights? A simple installation can compromise your home's safety by breaking the fire barrier1. Fire-rated downlights are your essential solution.

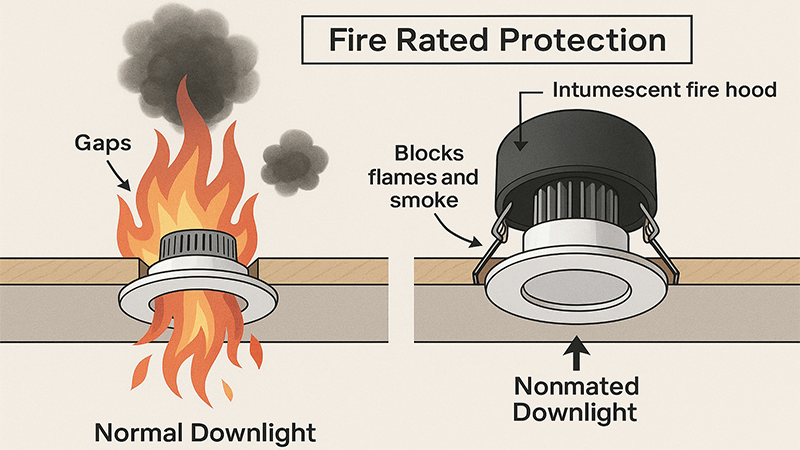

A fire-rated downlight is a recessed light designed to seal the hole it's installed in during a fire. It contains a special material that expands with heat, restoring the ceiling's fire barrier for up to 90 minutes and slowing the spread of fire and smoke between floors.

Understanding what they do is a great start. But you also need to know the rules that govern their use to ensure you're fully protected and compliant. It's simpler than you might think. Let's dig into the specifics so you can make safe and informed decisions for your projects.

What are the rules for fire rated downlights?

Navigating building regulations2 for lighting can be confusing. A single mistake could lead to non-compliance3 or, even worse, a serious safety failure during a fire.

The main rule is this: if you cut a hole in a fire-rated ceiling, you must restore its integrity. Fire-rated downlights are legally required in ceilings that separate habitable spaces, like those between floors in a house or between different apartments, to prevent fire from spreading.

The specific rules often come from national or local building codes. For example, in the UK, Document B of the Building Regulations outlines fire safety requirements4. When you install a recessed downlight, you create a hole in the plasterboard, which is a fire-resistant barrier. A standard downlight leaves that hole open for fire to pass through. A fire-rated downlight is designed to plug that gap when a fire breaks out. This is all about compartmentalization5—keeping the fire contained in one area for as long as possible to allow people to escape. This is a topic I always discuss with clients like Shaz, a purchasing manager in the UAE. For his large-scale projects, meeting strict building codes isn't just a suggestion; it's a legal requirement that protects lives.

Understanding Fire Ratings (30/60/90 Minutes)

Fire-rated downlights come with different time ratings. You will typically see 30, 60, or 90-minute ratings. This number tells you how long the downlight will maintain the ceiling's fire barrier. The rating you need depends on the type of ceiling construction.

| Fire Rating | Typical Use Case | Construction Type |

|---|---|---|

| 30-Minute | Standard domestic ceilings | Single-layer plasterboard with standard timber joists |

| 60-Minute | More robust domestic or commercial ceilings | Often double-layer plasterboard or specific floor builds |

| 90-Minute | High-spec commercial buildings and apartments | Concrete floors or highly specified fire-resistant structures |

Choosing the right one is critical. Installing a 30-minute downlight in a ceiling that requires a 60-minute rating creates a dangerous weak point. You must always match the downlight's rating to the ceiling's required fire resistance period6.

How to tell if a spot light is fire rated?

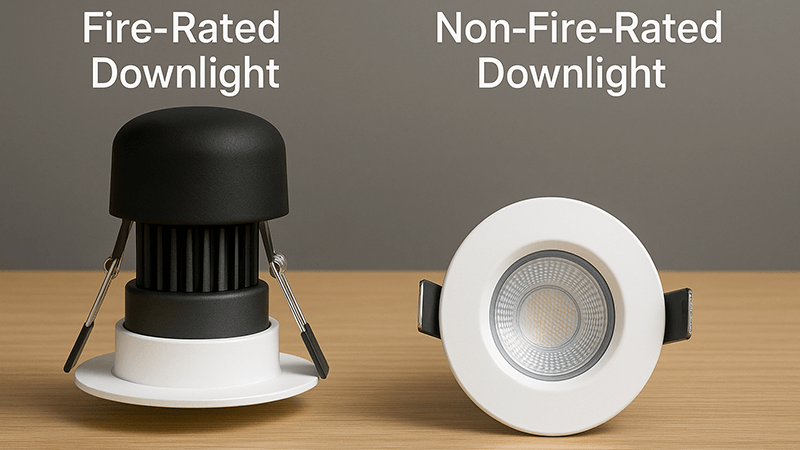

Looking at two downlights side-by-side, it's hard to tell them apart. But installing the wrong one creates a significant and hidden safety risk inside your ceiling.

To know if a spotlight is fire-rated, check the product itself or its packaging for official certification marks, like BS 4767. Physically, a fire-rated downlight is heavier and has a solid metal "can" on the back, covering the electronics, unlike the open-backed design of non-rated models.

When I'm showing products to clients, the physical difference is the first thing I point out. I remember Shaz was sent a sample from another factory. It looked fine from the front. But when we flipped it over, it was lightweight and completely open. I handed him one of our fire-rated models. He immediately noticed the extra weight and the solid steel enclosure that protects the internal components and houses the intumescent material8. You can feel the quality and safety built into it. That intumescent material, a special strip around the light, is the key ingredient. In a fire, it swells up to many times its size, creating a tight seal.

Key Visual and Physical Checks

Beyond just the feel, there are specific things you can look for to confirm a downlight is fire-rated. Always check for documentation from the manufacturer, as this provides the ultimate proof of testing and compliance. A reputable supplier will always provide a technical datasheet that clearly states the product's fire rating.

| Feature | Fire-Rated Downlight | Non-Fire-Rated Downlight |

|---|---|---|

| Construction | Solid, enclosed "can" on the back. Often made of steel. | Open back, you can see wires and spring clips. |

| Weight | Noticeably heavier due to more robust materials. | Very lightweight and feels flimsy. |

| Markings | Will have certifications (e.g., BS 476) and fire rating (e.g., 60 Min) printed on the product label. | No mention of fire ratings or related standards. |

| Intumescent Strip | A visible band of material around the can or bezel. | No such material is present. |

Are LED downlights a fire hazard?

Many people still worry that electric lights can overheat and cause a fire. This fear might stop you from embracing modern, energy-efficient lighting in your home or project.

High-quality, certified LED downlights are not a fire hazard. They operate at much lower temperatures than old halogen bulbs. The real risk comes from poorly made, cheap products, faulty installation, or improperly covering them with ceiling insulation, which can trap heat and create a danger.

This is a question I get all the time from both new and experienced buyers. It's a valid concern, especially for those who remember the old halogen downlights. Those things got incredibly hot. I’ve seen photos of scorch marks on wooden joists caused by halogen bulbs. Modern LEDs are completely different. The technology is designed for efficiency, meaning more energy is converted to light and less is wasted as heat. In my factory, a huge part of our design process is focused on thermal management9. A well-designed aluminum heat sink is non-negotiable. It draws heat away from the LED chip, which is crucial for both safety and ensuring the product lasts for its full 50,000-hour lifespan.

The Real Risks and How to Avoid Them

While quality LEDs are safe, certain factors can introduce risk. The good news is that these are all avoidable. The key is to buy from a trusted manufacturer and ensure the installation is done correctly by a professional. Never just go for the cheapest option you can find online without verifying its safety certifications10. Another critical point is insulation. If you plan to lay thermal insulation over your downlights, you must use lights that are specifically "insulation coverable" (IC-rated). This means they are designed to be safely covered without overheating.

| Common Risk | Solution |

|---|---|

| Poor Quality Product | Only buy products from reputable manufacturers with clear safety certifications (CE, UKCA, etc.). |

| Incorrect Installation | Always hire a qualified electrician to install your downlights. Faulty wiring is a major fire risk. |

| Covering with Insulation | Use IC-rated downlights if they will be in contact with insulation, or keep a safe clearance around non-IC lights. |

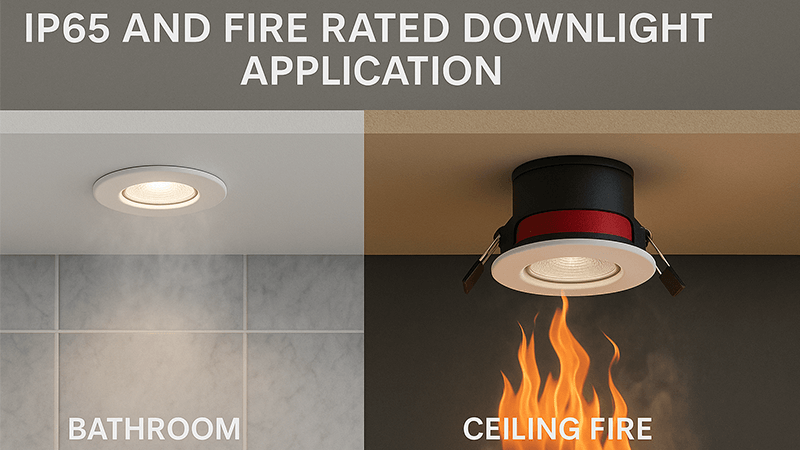

Are IP65 downlights fire rated?

Product codes and ratings can be confusing. You see IP65 and "fire-rated" and might assume one includes the other. This is a common and potentially dangerous misunderstanding.

No, an IP65 rating does not mean a downlight is fire-rated. IP65 describes its protection against dust and water, making it safe for bathrooms. Fire rating describes its ability to stop fire. The two are completely separate ratings for different safety functions, though you can buy a downlight that has both.

This is a perfect example of why product specification is so important. I work with professional buyers like Shaz who manage huge projects, and getting these details right is everything. Imagine a new hotel project. In the bathroom, you need a downlight that can handle the steam and moisture—that's where the IP rating comes in. "IP" stands for Ingress Protection. The first digit (6) means it's totally protected against dust. The second digit (5) means it's protected against low-pressure jets of water. But if that hotel bathroom is in a multi-story building, the ceiling is also a fire barrier between floors. In that case, you need a downlight that is both IP65 and fire-rated. You can't choose one or the other.

When You Need Both Ratings

Knowing when to specify a downlight with multiple ratings is key to ensuring total safety and compliance. It is not about one rating being better than another; it is about matching the product's features to the environment where it will be installed. You must consider both the location's physical conditions (Is it wet or dusty?) and its role in the building's overall fire safety plan11.

| Rating Feature | Protects Against... | Typically Used In... |

|---|---|---|

| IP65 | Dust ingress and low-pressure water jets. | Bathrooms, kitchens, outdoor soffits. |

| Fire-Rated | The spread of fire and smoke through a ceiling. | Ceilings between floors, escape routes, multi-unit buildings. |

So, for a bathroom on the ground floor of a single-story house, an IP65 downlight is sufficient. For an office below another office, a fire-rated downlight is needed. For a bathroom on the first floor of a house, you need a product that is both IP65 and fire-rated.

Conclusion

Fire-rated downlights are essential for maintaining a ceiling's fire barrier. Always check for official markings, understand that IP ratings are separate, and choose quality products for safety and compliance.

Learn about fire barriers and their critical role in fire safety in buildings. ↩

Understanding building regulations is essential for compliance and safety in construction. ↩

Learn about the serious consequences of failing to comply with fire safety regulations. ↩

This resource will help you navigate fire safety requirements effectively. ↩

Discover how compartmentalization can save lives during a fire. ↩

Understanding fire resistance periods can help you choose the right materials for safety. ↩

Explore the importance of BS 476 in ensuring fire safety compliance. ↩

Learn about intumescent materials and their role in fire-rated products. ↩

Discover how thermal management enhances the safety and longevity of LED lights. ↩

Explore essential safety certifications to look for when purchasing lighting. ↩

Learn how to create an effective fire safety plan for your property. ↩