Struggling with solid ceilings where you can't cut holes? Need a modern lighting solution without major renovations? A surface mounted downlight1 is your perfect answer.

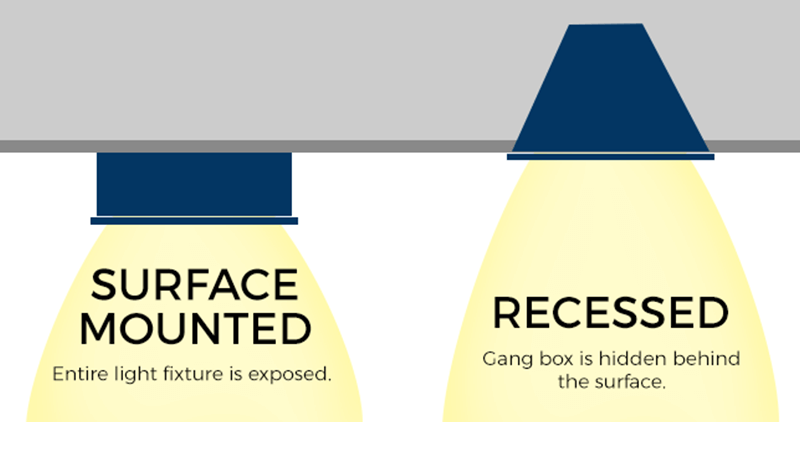

A surface mounted downlight is a self-contained light fixture that attaches directly to the surface of a ceiling. Unlike recessed lights, it doesn't require cutting a large hole into the ceiling, making it ideal for concrete slabs, historic buildings, or areas with limited ceiling void space.

When I first started in a lighting factory2 years ago, everything was about recessed downlights. They were the standard for a clean, modern look. But we kept getting requests from clients in Europe and the Middle East dealing with concrete slab ceilings. They couldn't just cut holes wherever they wanted. This practical problem forced us to innovate, and the surface mounted downlight evolved from a niche solution into a design statement. Now, it's a go-to product for contractors and designers who need flexibility without sacrificing style. It’s a perfect example of how a limitation can lead to a better, more versatile product. This article will walk you through everything you need to know about them, from selection to installation and the critical signs of quality.

What is the difference between surface downlight and recessed downlight?

Picking between downlights feels complex? Worried aboutchoosing the wrong one for your project's ceiling type? Understanding the core difference is key to a successful installation.

The main difference is installation. Recessed downlights are installed inside the ceiling, creating a flush, seamless look. Surface downlights are installed on the ceiling, making them visible. This makes them easier to install and maintain, especially on solid ceilings where recessing isn''t possible.

When helping a purchasing manager like Shaz decide on the right downlight, the conversation always goes beyond just the ceiling type. We're really talking about balancing aesthetics3, installation costs4, and long-term serviceability. I call this the "Contractor's Curse": the trade-off between a clean, integrated look and the ease of future maintenance. Recessed lights win on seamless aesthetics, but for a contractor, installing them in a difficult ceiling or servicing a failed driver can be a nightmare. Surface downlights, on the other hand, are a blessing for installation speed5 and ease of access. I remember a project for a hotel renovation where the client insisted on recessed lighting for its minimalist look, but the ceilings were a mix of old plaster and concrete. The labor costs for cutting and reinforcement skyrocketed. On their next project, we switched to high-end surface mounted downlights. Not only did they slash the installation budget, but the fixtures became a deliberate architectural feature6. They realized that a visible fixture7 isn't a compromise; it's a different style choice. This is the modern view of the surface downlight: it is an architectural statement, not just a problem-solver.

Key Differences at a Glance

| Feature | Surface Mounted Downlight | Recessed Downlight |

|---|---|---|

| Installation | Mounts directly onto the ceiling surface. No large hole needed. | Installed inside a cutout in the ceiling. |

| Aesthetics | Visible, cylindrical or square housing. Becomes a design element. | Flush with the ceiling. Minimalist and unobtrusive. |

| Best For | Solid ceilings (concrete, wood), low ceiling voids, retrofits. | Hollow ceilings (drywall, suspended grids) with ample space. |

| Maintenance | Easy to access, replace, or service the driver and LED module. | Can be difficult to access the driver, especially in sealed units. |

| Light Effect | Direct downward light, can also create pools of light. | Provides a clean, "wash" of light from an unseen source. |

This shift means that when you're sourcing these products, you should look for fixtures that are designed to be seen. Pay attention to the quality of the finish, the clean lines of the housing, and the overall design. It's no longer just about the light it produces, but the quality of the object itself.

How to install a surface downlight on a ceiling?

Worried about complex wiring and difficult installations? Afraid of making a mistake when mounting a new fixture? Installing a surface downlight is surprisingly straightforward for any professional.

To install a surface downlight, first turn off the power. Attach the mounting bracket to the ceiling with screws. Connect the fixture's wires to the main power supply. Finally, secure the downlight body to the bracket. Always consult a qualified electrician for safety.

The beauty of the surface mounted downlight is its simplicity, which saves time and money on job sites. I've walked factory floors and project sites for years, and the speed of a surface mount installation is always impressive. A good electrician can fit several in the time it takes to properly cut, fit, and secure one recessed downlight. However, simplicity can sometimes lead to carelessness if you aren't paying attention. The process is straightforward, but each step needs to be done correctly to ensure safety and a secure, lasting fit. The goal is a fixture that looks perfect and will not need to be touched again for years. I always advise contractors to standardize their process to avoid common mistakes.

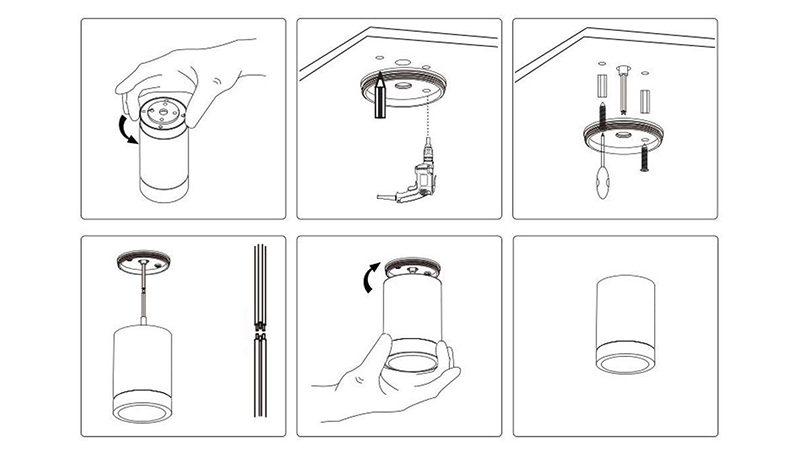

Step-by-Step Installation Guide

Step 1: Safety First

Before you do anything else, go to the circuit breaker and turn off the power to the area where you will be working. Use a voltage tester to double-check that the wires have no power. Safety is non-negotiable.

Step 2: Attach the Mounting Bracket

Most surface downlights come with a separate mounting bracket8. This small metal plate is the key to the whole installation. Position it on the ceiling where you want the light and mark the screw holes. Use the appropriate anchors and screws for your ceiling material—this is critical. Use expanding plastic anchors for drywall but metal or lead anchors for concrete. A wobbly bracket means a wobbly light.

Step 3: Connect the Wires

Carefully pull the ceiling's power wires through the center of the bracket. Typically, you'll have a live, a neutral, and a ground wire. Connect these to the corresponding wires on the LED downlight's driver or terminal block. Most of our iPHD fixtures come with quick-connect blocks to make this even faster and more secure. Ensure the connections are tight.

Step 4: Secure the Fixture to the Bracket

This is the final step. Align the downlight housing with the bracket. Depending on the design, it will either click into place or be secured with a couple of small, discreet screws on the side. Make sure it's snug against the ceiling with no gaps.

Step 5: Power On and Test

Go back to the breaker, restore power, and test your new light. It should turn on instantly with no flicker.

A common mistake I've seen is mismatched drivers. A contractor might have a box of spare drivers and grab one that fits physically but has the wrong voltage or amperage for the LED module9. This will cause flickering, poor performance, or premature failure. Always use the driver that was supplied and tested with that specific fixture.

What is the difference between ceiling mount and surface mount?

Confused by industry terms that seem to mean the same thing? Unsure if "ceiling mount" and "surface mount" are interchangeable? Let's clear up this common point of confusion.

Essentially, there is no difference. "Surface mount" describes how a fixture attaches (to the surface). "Ceiling mount" describes where it attaches (to the ceiling). The terms are often used interchangeably for lights that are not recessed, pendant, or track lights.

In my experience dealing with importers, distributors, and contractors from all over the world, this is a frequent question. The confusion is understandable because the terms are used so loosely. In the factory and on technical specification sheets, we almost exclusively use the term "surface mount." It is a precise technical description of the mounting method. It distinguishes the product from "recessed mount," "suspended mount," or "track mount." However, when talking to end-users or in marketing materials, "ceiling light" or "ceiling mount fixture" is more common because it's more descriptive for a general audience. They are looking for a light that goes on the ceiling. As a purchasing professional like Shaz, it's helpful to understand this nuance. When you write a purchase order or a technical query, using "surface mount" shows a deeper technical understanding and ensures there is no ambiguity. It signals to the manufacturer that you are specifying a precise type of product.

A Quick Guide to Mounting Terminology

To make it even clearer, here is a breakdown of the common mounting types you will encounter when sourcing lighting products. Understanding these will make your communications with suppliers much more efficient.

| Mounting Type | Technical Description | Common Name(s) | Example Fixtures |

|---|---|---|---|

| Surface Mount | Attaches directly to the flat plane of a surface (ceiling or wall). | Ceiling Light, Wall Sconce | Surface Downlights, "Oyster" Lights, Bulkheads |

| Recessed Mount | Installed within a cavity, so the fixture front is flush with the surface. | Recessed Light, Pot Light | Recessed Downlights, Troffers |

| Suspended Mount | Hangs from the ceiling via a cord, chain, or rod. | Pendant Light, Chandelier | Pendants, High Bays, Chandeliers |

| Track Mount | Attaches to an electrified track system on the ceiling. | Track Light | Spotlights, Linear Track Lights |

So, while a customer might ask for a "ceiling light," you know to source a "surface mounted downlight" that meets their aesthetic and functional needs. This clarity helps avoid confusion and ensures you order the exact product required for the job.

Why do LED downlights fail?

Frustrated by LED lights that burn out way before their promised 50,000-hour lifespan? Worried about the cost of callbacks and replacements? The reason for failure is rarely the LED itself.

Most LED downlights fail not because of the LED chip, but due to the failure of the electronic driver or overheating. Poor thermal management "cooks" the components, dramatically reducing lifespan and causing flickering, color shifts, or complete failure. Choosing quality is critical.

From my years in manufacturing, I can tell you that the single biggest determinant of an LED fixture's life is how well it handles heat. This is where we see the most significant difference between high-quality and low-quality products. It's also where some interesting design challenges appear.

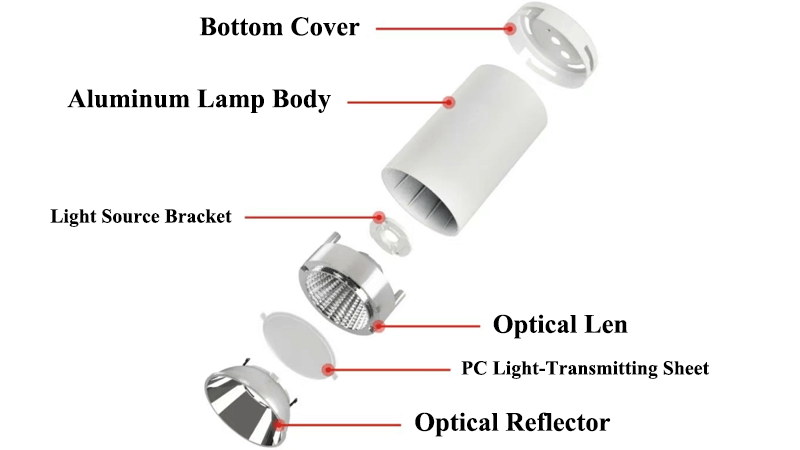

The Thermal Management Paradox

With a surface mounted downlight, the entire fixture is outside the ceiling. You would think this is great for cooling. But here’s the paradox: because it's a visible design element, some designers prioritize sleek, slim aesthetics over a chunky, effective heatsink. The body of the fixture is the heatsink. If it's made from thin, low-grade aluminum or doesn't have enough surface area (fins), it simply can't radiate the heat away from the LED chip and the driver. A well-designed recessed light might have a massive heatsink hidden in the cool ceiling void, but a poorly designed surface unit is trying to cool itself in the warm ambient air of the room. We rigorously test our fixtures in thermal chambers to ensure our heatsink designs work in the real world, not just on a computer screen.

The "Color Shift Cascade": A True Metric of Failure

For a professional, failure isn't just when the light goes out. A more common and frustrating failure is the "Color Shift Cascade." You install 50 downlights in a retail space, all a perfect 4000K neutral white. A year later, you get a call. Five of the lights now look yellowish, ten look stark white, and the rest are somewhere in between. The space looks messy and cheap. This color inconsistency is a direct result of thermal degradation. Overheating damages the phosphors on the LED chips and stresses the driver components, causing a gradual but irreversible shift in the color temperature and a drop in brightness. This is why we are so strict about the quality of the LEDs and drivers we source. A client’s reputation depends on consistency, and so does ours. When you're evaluating a sample, don't just look at the light when it's new. Ask for the LM-80 report for the LEDs and the thermal performance data for the fixture. This is how you spot a product built to last.

Conclusion

Surface mounted downlights offer a versatile, easy-to-install lighting solution. Understanding their design, installation, and key failure points ensures you choose quality products for every project you specify.

Explore the advantages of surface mounted downlights for modern lighting solutions without major renovations. ↩

Explore the latest innovations in lighting technology coming from modern lighting factories. ↩

Discover how the aesthetics of lighting can enhance the overall design of a space. ↩

Understand the key factors that influence the installation costs of different lighting fixtures. ↩

Understand the elements that can affect the speed of installing lighting fixtures. ↩

Explore how lighting can serve as a design statement in architectural projects. ↩

Learn how visible fixtures can add character and style to your interior spaces. ↩

Understand the importance of a mounting bracket for secure and effective lighting installation. ↩

Get insights into the functionality and benefits of LED modules in lighting fixtures. ↩