Struggling to get a clean, minimalist ceiling? Bulky downlight trims can interrupt your design. Trimless downlights integrate seamlessly, making the light source itself virtually disappear into the ceiling.

A trimless downlight is a recessed light fixture installed into the ceiling before plastering. It has a special housing that gets plastered over, leaving only the light aperture visible. This creates a smooth, continuous ceiling surface without any visible trim or flange.

This seamless look is incredibly popular, but achieving it is not as simple as just buying a different fixture. As a manufacturer for over a decade, I have seen where projects can go wrong if you are not careful. Understanding the key differences and installation challenges1 is critical for a successful project. Let's explore what truly sets these lights apart from their traditional counterparts.

What is the difference between trim and trimless downlights?

Choosing between downlight styles seems like a simple aesthetic decision. But the wrong choice can cause major installation issues and budget problems. Understanding the core differences protects your project's success.

Trimmed downlights are installed after the ceiling is finished, with a visible flange (the trim) covering the cutout's edge. Trimless downlights are installed before plastering. Their housing is plastered into the ceiling, making the fixture's edge invisible for a perfectly integrated look.

When you specify a trimless downlight over a standard one, you are making a choice that goes far beyond aesthetics. It changes the entire sequence of work on a project and, most importantly, it shifts who is responsible for the final quality of the finish. I call this the transfer of finish liability2.

The Shift in Responsibility

With a traditional trimmed downlight, the fixture itself provides the clean edge. The trim covers any imperfections in the plasterboard cut. The quality of the finish is largely dependent on the quality of our product. But with a trimless fixture, the game changes. The final, perfect finish around the light aperture is now created by the plasterer on site. This means the skill of the plasterer is more important than ever. If their work is not perfect, you will see cracks or an uneven surface. No matter how good my lighting product is, it cannot fix a poor plastering3 job. For a purchasing manager like Shaz, this means you must have confidence in your installation teams.

A Luminaire vs. An Architectural Feature

This leads to a bigger strategic shift. A standard downlight is a luminaire, an accessory you add to a finished ceiling. A trimless downlight is an architectural component4. It becomes part of the building's fabric. This simple fact has huge implications for project planning. It must be considered in the early architectural design and structural phase, not just at the electrical fit-out stage.

Here is a simple breakdown:

| Feature | Trim Downlight | Trimless Downlight |

|---|---|---|

| Installation Time | After ceiling is painted | Before final plaster skim |

| Required Trade | Electrician | Electrician + Plasterer |

| Finish Quality | Dependent on fixture quality | Dependent on plasterer's skill |

| Serviceability | Easy to remove/replace | Difficult; may require ceiling repair |

| Design Impact | Visible element on ceiling | Seamless, integrated into ceiling |

| Planning Stage | Late stage | Early architectural stage |

How do you install a trimless light?

You love the clean look of trimless lights. But a botched installation can create cracks and an uneven finish, ruining the entire effect. Knowing the key installation steps is vital.

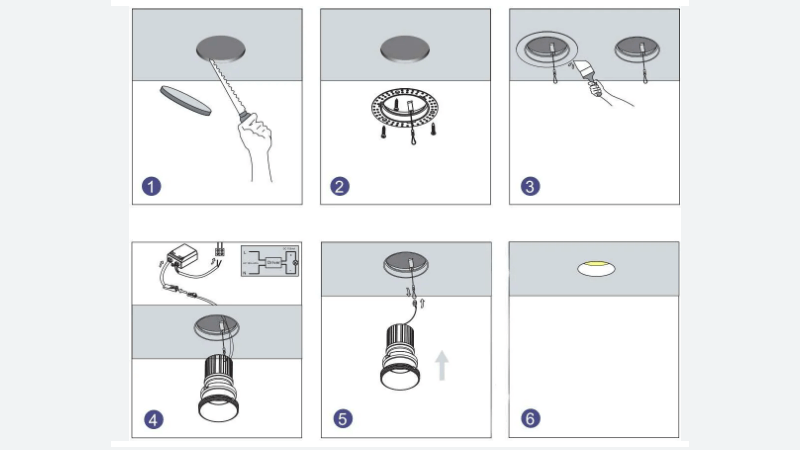

Installation involves cutting the hole, fitting the plaster-in frame5, and securing it to the ceiling structure. The plasterer then applies plaster right up to the frame's edge and skims over its perforated flange. After painting, the main light engine6 is inserted into the housing.

The installation process7 is where the beautiful theory of trimless lighting8 meets hard reality. It's a multi-stage, multi-trade process that must be coordinated perfectly. But beyond the visible steps, there are hidden challenges9 that affect the light's performance and lifespan, which I always focus on during product development.

The Hidden Challenge of Heat

One of the biggest issues we had to solve as manufacturers was thermal management10. A trimless downlight is completely encased in plasterboard and plaster. This environment is an excellent insulator, which is terrible for electronics. It becomes a thermal trap. Heat is the number one enemy of an LED chip. If it cannot dissipate heat effectively, its lifespan and performance will drop dramatically. A standard LED engine would fail very quickly in these conditions. That is why we had to design specialized heat sinks and internal airflow systems specifically for our trimless models. When sourcing these products, you must ask suppliers about their thermal management solution. A low-cost product has likely cut corners here, and it will lead to failures down the line.

Thinking About the Future: The Lifecycle Cost Paradox

Here is the paradox: trimless lights look premium and expensive, but the real cost can show up years later during maintenance. The seamless integration makes serviceability11 a huge challenge. With a standard downlight, if a driver fails, you pop the light out, replace the driver, and pop it back in. With a poorly designed trimless fixture, you might have to cut open the ceiling to access a failed component. This turns a simple maintenance task into a costly repair job involving plasterers and painters. We solved this by designing our trimless range with a modular system12. The light engine and driver can be removed from the front, through the aperture, without ever touching the ceiling. This is a critical feature that lowers the total cost of ownership significantly.

What is a flangeless recessed light?

Heard terms like "flangeless" or "plaster-in" and felt confused? Using the wrong term can lead to sourcing the incorrect product. These terms are simpler than they sound when you look closer.

A flangeless recessed light is simply another name for a trimless downlight. The term "flangeless" directly refers to the absence of the visible rim or flange that a traditional downlight has. Both terms describe a light that is plastered into the ceiling.

In the industry, we often use these terms interchangeably. "Trimless," "flangeless," and "plaster-in" all point to the same minimalist aesthetic. However, focusing only on the name can cause problems. The real understanding comes from looking at the product as a system, not just a name.

My Experience with Confused Terminology

I remember a project contractor client a few years ago. He kept sending RFQs for "flangeless" lights. From his emails, I could tell he was thinking of a product with a very thin, minimal bezel, not a true plaster-in system. His team installed the products after the ceiling was finished, and he was furious that the look wasn't the seamless, "light from nowhere" effect he saw in magazines. This simple breakdown in communication cost his project significant time and money, as they had to find a different solution. It was a powerful lesson for me. It highlighted that we, as manufacturers, must be crystal clear about the process required, not just the name of the product. The "flangeless" result is a combination of the right product and the right installation method.

Deconstructing the "Plaster-In Kit"

When you source a trimless or flangeless light, you are typically buying a two-part kit.

- The Plaster-in Frame: This is the architectural component. It gets fixed to the ceiling structure and plastered over. The quality of this part is crucial. It must be rigid and strong to prevent the plaster from cracking around it over time due to building vibrations or temperature changes.

- The Light Engine: This is the luminaire part, containing the LED, lens, and heatsink. This module is installed after all the messy plastering and painting is done. The quality here relates to light output, color consistency, and critically, how it manages heat and how it can be serviced. A good system allows this engine to be removed easily from the front.

What does trimless mean?

You know "trimless" means no visible edge. But its real meaning affects construction schedules, trade coordination, and long-term maintenance. Understanding this helps you manage projects more effectively.

"Trimless" literally means "without a trim" or "without a border." In lighting, it describes a method of installation where the fixture's housing is hidden within the ceiling, making the fixture appear to be an integral part of the architectural surface.

The word "trimless" is more than a descriptor; it is a signal. It signals a fundamental shift in how you must approach that part of a project. When you see "trimless" on a specification sheet, it tells you that you are no longer just buying a product. You are buying into a process.

From Product to Process

A trimless installation is a process that involves multiple trades that must work in a specific sequence. The electrician mounts the frame. The plasterer integrates it into the ceiling. The painter finishes the surface. Finally, the electrician returns to install the light engine. If this chain is broken, or if the coordination fails, the project will have problems. As a purchasing manager, your responsibility extends to ensuring the supplier provides clear, detailed installation instructions13 that can be shared with all trades involved. The product must support the process.

The Hidden Liabilities of Going Trimless

Ultimately, "trimless" brings two hidden liabilities that you must manage.

- Finish Liability: As I mentioned, the final aesthetic quality is controlled by the on-site contractor, not the lighting manufacturer. You must budget for skilled labor to get the premium finish you are paying for.

- Service Liability: The long-term cost of maintaining, repairing, or replacing a trimless fixture can be very high if you choose the wrong product. A cheap, fully integrated unit could necessitate ceiling demolition for a simple driver failure. This is a massive risk to the total lifecycle cost of the installation.

To protect your project, here is a strategic checklist to use when sourcing trimless lights:

- Frame Quality: Is the plaster-in frame robust and made from a stable material to prevent cracking?

- Serviceability: Is the light engine module easily removable from the front without damaging the ceiling?

- Instructions: Does the supplier provide clear, multi-trade installation documentation?

- Thermal Design: What specific features does the light have to manage heat in an enclosed, insulated space?

Conclusion

Trimless downlights offer a superb minimalist look, but require careful planning. Success depends on seeing them as architectural components that demand quality installation, thermal design, and easy serviceability.

This resource outlines potential installation challenges and how to overcome them. ↩

Explore this concept to grasp the implications of finish quality in projects. ↩

Discover the plastering process and its importance in achieving a smooth finish. ↩

Learn how architectural components influence design and installation processes. ↩

Learn about the role of plaster-in frames in achieving seamless lighting. ↩

Discover the components of a light engine and its significance in lighting design. ↩

Get insights into the step-by-step installation process for trimless downlights. ↩

Explore the aesthetic and functional benefits of trimless lighting solutions. ↩

Learn about the often-overlooked challenges that can impact lighting performance. ↩

Discover the importance of thermal management for LED longevity and performance. ↩

Explore the importance of serviceability in lighting fixtures for long-term use. ↩

Understand how modular systems can simplify maintenance and repairs in lighting. ↩

Learn how clear installation instructions can prevent costly mistakes in projects. ↩