Picking the wrong lights means frequent, costly replacements. This frustration adds up. High-quality COB LED downlights offer a long-lasting, efficient solution that saves you money and hassle over time.

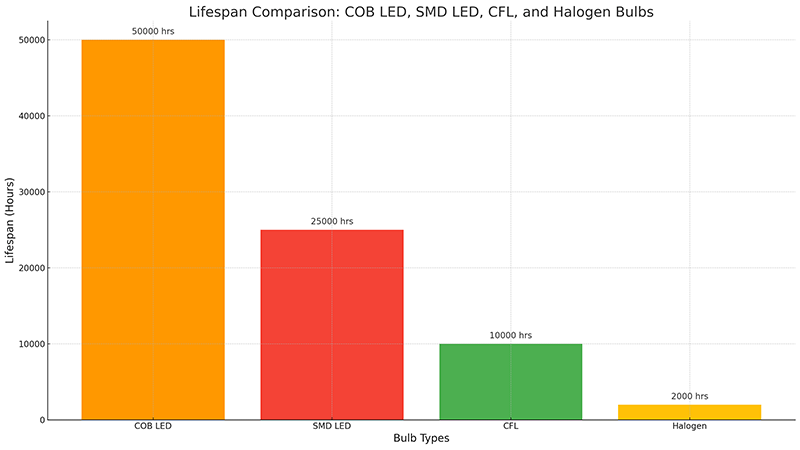

COB (Chip on Board) LED downlights have an excellent lifespan, typically lasting between 30,000 and 50,000 hours. This is significantly longer than traditional halogen bulbs (1,000-2,000 hours) and even surpasses many standard SMD (Surface Mounted Device) LED options, making them a durable and cost-effective choice.

I've been in the LED lighting business for a long time, from my start on the factory floor to founding my own company. I've seen firsthand how choosing the right technology impacts a project's long-term success. Lifespan is a critical factor, but it's not the only one. Many of my clients, like Shaz, a purchasing manager in the UAE, also ask about brightness, health impacts, and customization. Let's break down these common questions to give you a complete picture.

How long does a COB LED really last?

You're investing in new lighting and need to be sure it will last. Choosing a product that fails early means going over budget and dealing with unhappy clients. It's a real headache.

The long lifespan of a COB LED, typically 30,000 to 50,000 hours, is due to its superior design for heat dissipation. Because the LED chip is mounted directly to a substrate, heat can escape more efficiently, which is the key factor in extending the life of any LED.

In my years of manufacturing, I've learned that not all COB LEDs are created equal. The lifespan numbers you see on a box are only possible if the product is built with quality materials. Heat is the number one enemy of an LED's lifespan1 and color quality. If you can't get heat away from the chip effectively, the light will degrade quickly.

The Critical Role of Packaging Material

The material used to package the COB chip makes a huge difference. This is a detail I always discuss with experienced buyers like Shaz, because it directly impacts performance. There are two common options: plastic and ceramic. Plastic is cheaper, but it's terrible at conducting heat. Ceramic is an excellent thermal conductor.

Based on my factory experience and extensive testing, I can share a key insight: using a ceramic-packaged COB2 can reduce thermal resistance3 by 30% or more compared to a plastic one. This superior heat dissipation4 prevents the chip from overheating. A COB LED with plastic packaging can start to yellow and lose significant brightness in as little as 3,000 hours. A ceramic-packaged one will maintain its quality for tens of thousands of hours. At Upward Lighting, we insist on ceramic substrates for our COB products because we’re committed to quality that lasts.

Lifespan Compared to Other Technologies

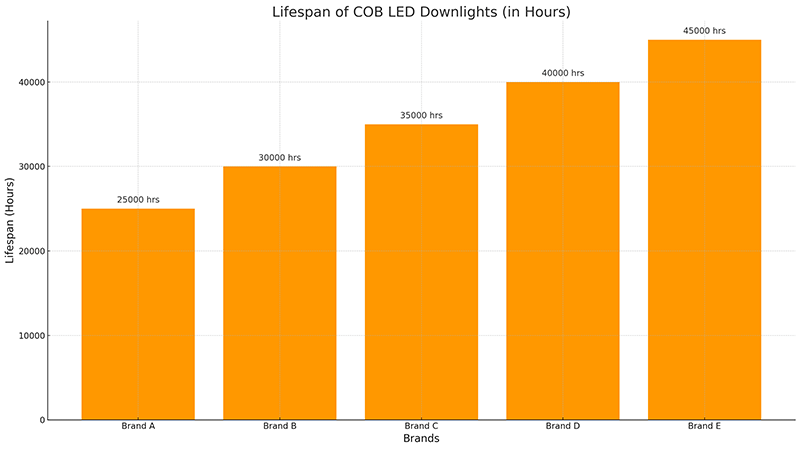

To put it in perspective, let's look at the numbers.

| Light Source | Average Lifespan (Hours) | Key Characteristic |

|---|---|---|

| COB LED | 30,000 - 50,000 | Excellent heat dissipation, long life |

| SMD LED | 25,000 - 50,000 | Good lifespan, but can vary by quality |

| Halogen | 1,000 - 2,000 | Very short life, high heat output |

| CFL | 8,000 - 10,000 | Decent life, contains mercury |

| Incandescent | ~1,000 | Extremely short life, very inefficient |

When you choose a COB LED downlight, you're not just buying a light; you're investing in a solution that will perform reliably for years.

Is a COB LED brighter than a regular LED?

You're trying to light a space and are confused by the different LED types. Choosing the wrong one could leave you with weak, uneven lighting, forcing you to start over.

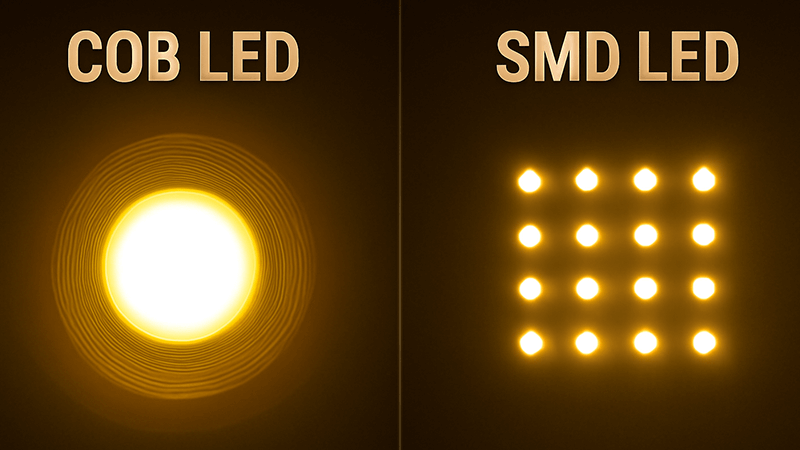

Yes, in many applications, COB LEDs are brighter. They achieve this through high lumen density5, packing many small LED chips into a single module. This creates an intense, uniform beam of light from one source, appearing much brighter than multiple, separate SMD chips of the same total power.

When clients ask me "which is brighter?", I always reframe the question to "which is right for your application?". The term "regular LED" usually refers to SMD (Surface Mounted Device) technology. Both COB and SMD are fantastic, but they shine in different ways.

Understanding Lumen Density

Brightness in LEDs is about more than just a number; it's about how the light is delivered. COB technology excels at creating high lumen density. Imagine you have 100 tiny light sources.

- SMD technology6 spreads those 100 sources out over a larger circuit board. You see multiple points of light.

- COB technology puts all 100 of those sources into a space the size of a thumbnail.

This concentration of light sources makes COB LEDs incredibly intense and powerful. It allows us to create a strong, focused beam from a very compact fixture, which is perfect for downlights7, spotlights8, and track lights where you need to punch light over a distance.

Application: COB vs. SMD

Choosing between COB and SMD depends entirely on the desired effect. Neither is universally "better," they are just suited for different jobs. This is something I work through with project contractors all the time to match the product to their vision.

| Feature | COB (Chip on Board) LED | SMD (Surface Mounted Device) LED |

|---|---|---|

| Light Appearance | Intense, uniform, single light source | Multiple points of light, can create glare |

| Best For | Downlights, spotlights, high-bay lights9 | Strip lights, linear fixtures, panel lights |

| Beam Quality | Smooth, controlled beam with no spots | Can have a "dotted" or multi-shadow effect |

| Heat Management | Excellent, direct path to heat sink | Good, but heat must travel from each chip |

| Typical Use Case | Creating focused, high-impact accent lighting | Creating broad, diffuse area lighting |

For a high-end retail store where you want to spotlight a product with a sharp, clean beam of light, COB is the clear winner. For creating a seamless line of light under a cabinet, an SMD strip light is the perfect tool.

What is the healthiest alternative to LED lights?

Many people are concerned about the "blue light" from LEDs and its effect on health. This worry can make choosing lighting for homes and offices a stressful and confusing process.

The healthiest lighting isn't about avoiding LEDs, but choosing the right LED. The best options are LEDs with a high Color Rendering Index (CRI >90) and a warm Correlated Color Temperature (CCT <3000K), especially for evening use, as they mimic natural light and reduce blue light exposure10.

As a manufacturer, I take this concern seriously. We're not just making light; we're creating environments where people live and work. The goal of "human-centric" lighting is to support our natural body clock, or circadian rhythm, not disrupt it. The good news is that modern LED technology gives us amazing control over the quality of light.

Taming the Blue Light

The concern about LED lighting comes from the high amount of blue wavelength light that some LEDs produce. Our bodies associate blue light with daytime, so too much of it at night can interfere with our ability to produce melatonin, the hormone that helps us sleep. However, not all LEDs are the same. We can control the amount of blue light by focusing on two key metrics: CCT and CRI.

How to Choose Health-Conscious LEDs

When I help clients specify lighting for residential or hospitality projects, we focus heavily on creating a comfortable, healthy atmosphere. It comes down to these two simple factors:

- CCT (Correlated Color Temperature): This measures how "warm" or "cool" the light appears, measured in Kelvin (K). For relaxing spaces like bedrooms and living rooms, you want a warm CCT, similar to a sunset or firelight. A lower number means warmer light with less blue content.

- CRI (Color Rendering Index): This measures how accurately a light source reveals the true colors of objects, on a scale of 0-100. Natural sunlight has a CRI of 100. A high CRI (90+) light feels more natural and comfortable to our eyes.

Here’s a simple guide for choosing the right CCT:

| CCT Value | Light Appearance | Best For | Psychological Effect |

|---|---|---|---|

| < 3000K | Warm White | Bedrooms, Living Rooms, Restaurants | Relaxing, cozy, intimate |

| 3000K - 4000K | Neutral White | Kitchens, Offices, Retail | Alert, focused, clean |

| > 5000K | Cool White | Garages, Warehouses, Hospitals | High energy, clinical, intense |

By choosing a high CRI, warm CCT LED, you get all the benefits of energy efficiency11 and long life without the harsh, blue-heavy light that causes concern.

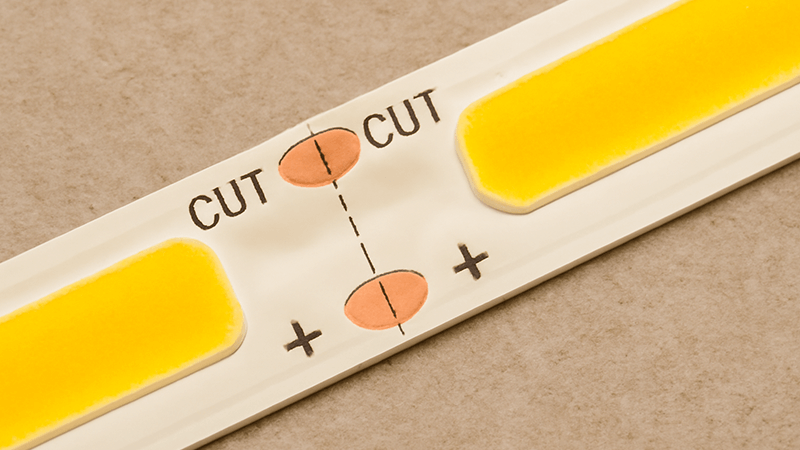

Can a COB LED be cut?

You have a great idea for a custom lighting project12, but you're not sure if the lights can be sized to fit. You’re worried you might buy something that you can't adapt, wasting time and money.

This depends on the format. A single COB chip itself cannot be cut; it is an integrated electronic component. However, COB LED strips are specifically designed to be cut at designated markings, allowing you to easily customize the length for your project.

This is a question that highlights the innovation happening in the LED world. We're moving beyond standard bulbs to more flexible and integrated lighting solutions13. As an ODM/OEM provider, creating custom solutions is what we do, so I understand the need for products that can be adapted on-site.

Why You Can't Cut an Individual Chip

A single COB chip is a marvel of engineering. It's a collection of tiny diodes, wiring, and phosphor coating all bonded to a single substrate. Think of it like the processor in your computer. If you were to cut it in half, you would sever the intricate circuits inside, destroying it completely. The entire component is designed to work as one indivisible unit to produce light efficiently. Trying to cut a bare COB chip will simply ruin it.

The Design of a COB LED Strip

COB LED strips14, on the other hand, are designed for customization. The product isn't one long COB chip. Instead, it's made of many small, independent COB segments mounted onto a long, flexible printed circuit board (FPC). These segments are wired in parallel, so you can cut the strip between segments without damaging the rest of the circuit.

Here’s how you can safely customize a COB LED strip:

- Identify the Cut Lines: Look for the designated cut marks on the strip. They are usually indicated by a scissor icon or a black line across copper pads.

- Measure and Mark: Measure the length you need and find the closest cut line. You can only cut on these specific lines.

- Make the Cut: Use a pair of sharp scissors to make a clean, straight cut across the marked line.

- Add a Connector: To power the newly cut section, you can either solder wires directly to the copper pads or, for a much easier solution, use a solderless "clip-on" connector designed for the specific width of your COB strip.

This ability to cut and reconnect COB strips opens up endless possibilities for custom jobs, like perfect-fit under-cabinet lighting or seamless architectural accents15, which we help clients design all the time.

Conclusion

COB LED downlights16 offer a fantastic combination of long lifespan, powerful brightness, and design flexibility. By choosing quality materials and the right specifications, you get a lighting solution that performs beautifully for years.

Learn about the impressive lifespan of COB LED downlights compared to traditional lighting. ↩

Discover why ceramic packaging enhances the performance of COB LEDs. ↩

Find out how thermal resistance impacts LED performance and longevity. ↩

Understand how heat dissipation affects the performance and lifespan of LED lights. ↩

Explore the concept of lumen density and its significance in lighting applications. ↩

Learn about SMD technology and how it compares to COB technology. ↩

Explore the various applications and benefits of using downlights in spaces. ↩

Understand the benefits of spotlights for focused lighting in various settings. ↩

Learn about high-bay lights and their ideal applications in commercial spaces. ↩

Learn about the effects of blue light exposure and how to mitigate them. ↩

Discover how LED technology contributes to energy savings and sustainability. ↩

Get tips on designing custom lighting solutions using LED technology. ↩

Explore various lighting solutions to enhance the ambiance and functionality of spaces. ↩

Discover the versatility and applications of COB LED strips in lighting design. ↩

Learn how to use lighting creatively to highlight architectural features. ↩

Explore the advantages of COB LED downlights for energy efficiency and longevity. ↩