Are you tired of high energy bills and constantly replacing burnt-out bulbs? CFLs were a step up, but their efficiency and lifespan can be a letdown, impacting your project's budget.

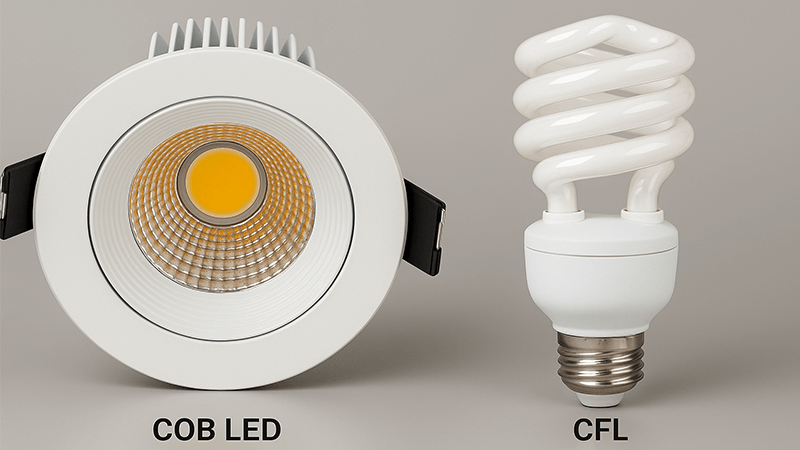

COB LED downlights are more energy-efficient because they convert a higher percentage of electricity directly into light, losing very little as heat. This superior efficacy, measured in lumens per watt, makes them a far better choice than older CFL technology for saving energy and costs.

It's easy to look at the specifications and see that one light is better than another. But as a purchasing manager, you need to know why. Understanding the core reasons for this efficiency gap helps you make powerful, long-term decisions for your projects. I've spent my entire career in the lighting industry1, from the factory floor to founding my own company, and I've seen this technology evolve firsthand. Let’s break down exactly what gives COB LEDs their winning edge, so you can explain your choices with complete confidence.

Why is LED more efficient than CFL?

Your projects demand the best efficiency, but the technical differences between lighting types can be confusing. Choosing the wrong one means wasting your client's energy and money for years to come.

LEDs are more efficient because they use a semiconductor to create light directly—a process called electroluminescence2. CFLs use a two-step process, exciting gas to create UV light that then activates a phosphor coating. This indirect method wastes significant energy as heat.

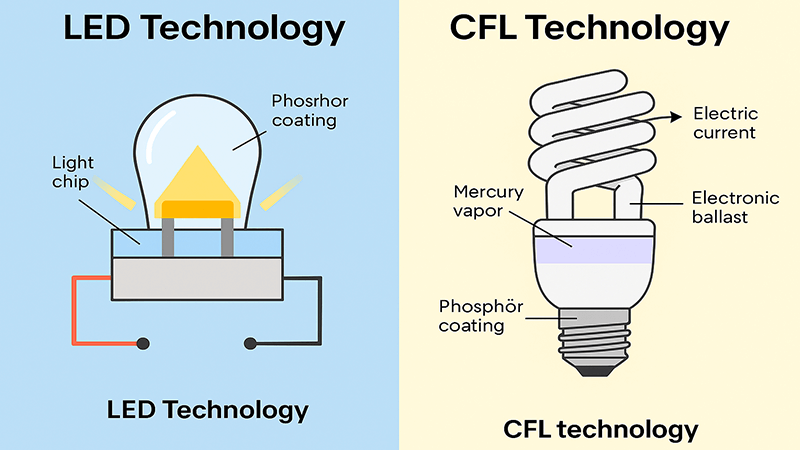

The Science of Light Creation

Let's dive deeper into how these two technologies actually work. The difference in their efficiency is rooted in their fundamental design.

An LED, or Light Emitting Diode, is a solid-state device. It doesn't have filaments or gases. Instead, it has a small semiconductor chip. When you pass electricity through this chip, it excites electrons, which then release their energy as photons—tiny particles of light. This process is called electroluminescence. It's a very direct and controlled way of turning electricity into light. Because the conversion is so direct, very little energy is wasted as heat. This is why a high-quality 10W LED can easily replace an old 75W incandescent bulb.

A CFL, or Compact Fluorescent Lamp, works very differently. It’s essentially a miniature version of the long fluorescent tubes you see in offices. Inside the twisty glass tube is a mix of argon gas and a small amount of mercury vapor3. When you turn it on, an electrical current flows through the tube, exciting the gas and causing it to produce invisible ultraviolet (UV) light. This UV light then strikes a white phosphor coating4 on the inside of the tube, which in turn glows, or "fluoresces," to produce the visible light we see. This two-step process is inherently inefficient. Energy is lost when generating the UV light, and more is lost during the conversion to visible light. Much of this wasted energy is released as heat.

I remember back in the factory when we were testing early prototypes. The heat sink for an LED was designed to manage a small, predictable amount of heat. But when we tested the CFLs, their ballasts would get incredibly hot. That heat isn't just a byproduct; it's wasted electricity you’re paying for.

| Feature | LED (Light Emitting Diode) | CFL (Compact Fluorescent Lamp) |

|---|---|---|

| How it Works | Electroluminescence (Solid-State) | Gas-Discharge & Fluorescence |

| Energy Conversion | Direct (Electricity to Light) | Indirect (Electricity > UV > Light) |

| Primary Energy Loss | Minimal Heat | Significant Heat & Conversion Loss |

| Average Efficacy (lm/W) | 80-150+ | 50-70 |

| Starts Instantly? | Yes | No, often has a warm-up time |

This fundamental difference is why the industry has moved so decisively toward LEDs. It's simply a more elegant and efficient way to create light.

What is the most energy efficient lighting option?

You’re sourcing for a landmark project and need the absolute best-in-class efficiency. With so many "energy-saving" options on the market, choosing the true champion can feel like a gamble.

The most energy-efficient lighting5 commercially available today is the LED. Specifically, high-quality Chip-on-Board (COB) LED6s often lead the pack for applications like downlights, combining high lumen output with excellent thermal management for maximum efficacy (lumens per watt7).

A Spectrum of Efficiency

While LED is the clear winner overall, it's important to understand that not all LEDs are created equal. The lighting industry1 is constantly innovating, and there are different tiers of efficiency even within the LED category.

The gold standard for many commercial applications today is the Chip-on-Board (COB) LED6. This technology mounts multiple LED chips directly onto a single substrate to form one powerful module. This design has a few key advantages for efficiency. First, it allows for a very dense array of light sources in a small area, creating a powerful, single point of light that is easy to control with reflectors and lenses. This means less light is wasted inside the fixture. Second, the direct mounting onto a substrate creates a more efficient path for heat to escape to the heat sink. Better thermal management8 means the LED runs cooler, and a cooler LED is a more efficient LED. Its performance degrades less over its lifetime.

My insight here, based on years of manufacturing, is crucial for you as a buyer. The design of the heat sink is everything. A poorly designed fixture will cause the COB chip to overheat, drastically reducing both its efficiency and lifespan. This is why, at my company, CFD (Computational Fluid Dynamics) thermal simulation is mandatory in the design phase of every COB downlight. We aim for a prediction error of 10% or less. Without this simulation, you're just guessing. A small error in heat sink design9 can lead to massive real-world performance failures, and that's a risk we never take.

Let’s look at a table comparing common lighting options:

| Lighting Type | Typical Efficacy (Lumens/Watt) | Key Characteristics |

|---|---|---|

| Incandescent | 10-17 lm/W | Very inefficient; 90% energy lost as heat. Phased out. |

| Halogen | 15-25 lm/W | A slight improvement on incandescent, but still very inefficient. |

| CFL | 50-70 lm/W | A good step up, but contains mercury and has a shorter lifespan. |

| SMD LED | 80-120 lm/W | Very common, efficient, flexible for many applications (e.g., strips). |

| COB LED | 90-150+ lm/W | Excellent efficacy, high-intensity light, great for downlights and spotlights. |

When you’re looking for the absolute most energy-efficient option for downlights10 or spotlights, a well-designed COB LED fixture is almost always the answer. It represents the peak of commercially viable lighting technology today.

How many diodes are there in a COB LED at least?

You're reviewing a spec sheet and see "COB LED," but what does that really mean? Is it one big chip, or a bunch of small ones? Knowing the details helps you verify quality.

A Chip-on-Board (COB) LED consists of multiple diodes, typically 9 or more, mounted directly on a single substrate. There is no official minimum, but having fewer than 9 diodes would generally defeat the purpose of the COB design, which is to create a dense, powerful light source.

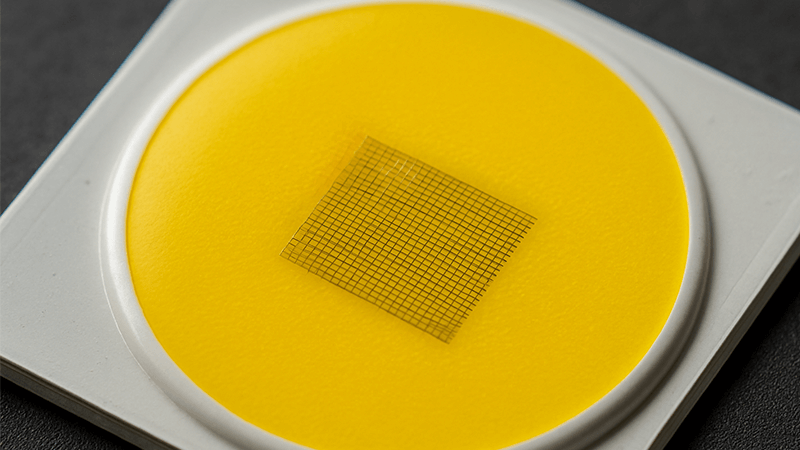

Unpacking the Chip

The term "Chip-on-Board" is very descriptive of how this technology is made. Let's break it down to understand its structure and why the number of diodes matters.

Instead of packaging each LED diode individually (like in SMD LEDs), COB technology takes the raw, unpackaged diodes and mounts them directly onto a circuit board or a ceramic/aluminum substrate. These diodes are tiny—often less than a square millimeter each. Once they are all placed in a tight cluster, the entire array is covered with a single layer of yellow phosphor. This is what you see when you look at a COB LED—a solid yellow circle or square. When the blue light from the diodes underneath passes through this phosphor, it's converted into the white light we use for illumination.

So, why at least 9 diodes? It comes down to the purpose of COB: light density11. The primary advantage of COB is to pack a huge amount of light output into a very small area, creating the effect of a single, powerful light source. This is perfect for directional lights like downlights and spotlights where you need a strong, focused beam. If you only used a few diodes, say 3 or 4, you could achieve that with individual high-power SMD LEDs. The "cluster" approach only becomes beneficial when you have a higher number of diodes working together. A typical 10W COB downlight might have anywhere from 12 to 28 diodes, while higher-power industrial lights could have hundreds.

From a manufacturing perspective, building a COB requires incredible precision. The diodes must be placed perfectly, and the phosphor coating4 must be applied evenly. An uneven coating will result in color inconsistencies across the beam—something a discerning client would notice immediately. I’ve seen production lines where a microscopic error in diode placement led to an entire batch being rejected. This is why it’s so important to work with manufacturers who have mastered this process.

Here’s a quick reference:

| LED Assembly Type | Diode Arrangement | Typical Application | Key Benefit |

|---|---|---|---|

| DIP (Dual In-Line) | Single, large, lensed diode | Old indicator lights, signs | Low cost, durable |

| SMD (Surface Mount) | Individually packaged diodes | Strip lights, linear fixtures, bulbs | Versatility, good heat dissipation |

| COB (Chip-on-Board) | 9+ unpackaged diodes in a cluster | Downlights, spotlights, high bays | High light density, single point source |

When you see "COB" on a spec sheet, you can now picture a dense cluster of at least 9 tiny diodes working together under a single phosphor lens to create that powerful, efficient light.

Which is better, SMD or COB LED?

You're comparing two downlights. One uses SMD LEDs, the other uses COB. The specs look similar, but the price is different. You need to know which one is truly better for your project.

Neither is universally "better"; they are suited for different applications. For downlights and spotlights requiring a focused, high-quality beam similar to a halogen, COB is superior. For linear lights, panels, or bulbs that need wide, even light distribution, SMD is better.

Choosing the Right Tool for the Job

Thinking about SMD vs. COB is like comparing a paintbrush to a paint sprayer. Both are used for painting, but you wouldn't use a sprayer for fine details, and you wouldn't use a small brush to paint a giant wall. The same logic applies here. The 'better' choice depends entirely on the lighting effect you want to achieve.

SMD (Surface Mounted Device) LEDs are individual chips that are soldered onto a circuit board. You can see them as separate points of light. Because they are spread out, they are perfect for creating a wide, diffuse, and even field of light.

- Best for: LED strip lights, panel lights, and bulbs where you want to avoid hotspots and create a smooth, glare-free glow.

- Light Quality: Tends to produce a more scattered, multi-shadow effect because the light originates from multiple small sources spread over an area.

COB (Chip-on-Board) LEDs, as we've discussed, pack many chips into a tiny area to create what appears to be a single, large light source. This design is built for intensity and control.

- Best for: Downlights, track lights, and spotlights where you need a strong, controllable beam of light.

- Light Quality: It creates a single, clean shadow, much like a traditional halogen bulb. This is often seen as a higher-quality light for accent and focused task lighting, as it renders objects with crisp definition.

During my career, I've helped many clients make this exact choice. For a hotel lobby that needed dramatic accent lighting on artwork, COB was the only option. For the general back-of-house corridor lighting, the diffuse light from SMD fixtures was more practical and cost-effective.

| Feature | SMD (Surface Mounted Device) | COB (Chip-on-Board) |

|---|---|---|

| Light Source | Multiple, separate points of light | A single, dense point of light |

| Light Quality | Diffused, scattered, multi-shadow | Focused, intense, single-shadow |

| Best Application | Linear lights, Panels, General area | Downlights, Spotlights, Accent lighting |

| Beam Control | Harder to control precisely | Excellent when paired with optics |

| Thermal Path | Good (each chip has a path) | Excellent (direct path to substrate) |

For your specific needs in sourcing high-quality downlights for commercial and residential projects, COB is almost always the better choice. It delivers the performance, efficiency, and aesthetic quality that your discerning customers expect.

Conclusion

COB LED technology is more efficient than CFLs due to its direct energy-to-light conversion. For your projects, choosing well-designed COB downlights ensures superior energy savings, longevity, and light quality12.

Stay updated on the latest trends and innovations in the lighting industry. ↩

Learn about the science behind electroluminescence and its role in LED efficiency. ↩

Learn about the role of mercury vapor in CFL technology and its implications. ↩

Explore the function of phosphor coating in converting UV light to visible light. ↩

Discover the latest in energy-efficient lighting solutions to reduce costs and environmental impact. ↩

Learn why COB LED technology is preferred for high-intensity lighting applications. ↩

Find out why lumens per watt is a crucial metric for evaluating lighting efficiency. ↩

Explore the importance of thermal management in maximizing LED performance and lifespan. ↩

Learn about the critical role of heat sink design in LED lighting efficiency. ↩

Find out which downlights offer the best energy efficiency for your applications. ↩

Learn about light density and its significance in COB LED performance. ↩

Understand the impact of light quality on design and functionality in lighting. ↩