Unsure which datasheets you can trust? You see amazing performance numbers, but your real-world experience doesn't match. You suspect the data you’re given isn't the whole truth.

The best buyers look beyond the surface of a test report. They verify testing conditions like temperature and warm-up time, question the difference between sample and mass production quality, and understand that LED chip lifespan (LM-80) does not equal the actual lifespan of the entire downlight fixture.

I’ve spent my entire career in the LED lighting industry, from the factory floor to founding my own company. I’ve seen countless test reports that promise the world. But I also know what happens behind the scenes to produce those perfect numbers. The difference between what a report says and what a product delivers can be huge, and that gap can cost you money and damage your reputation. Let’s pull back the curtain and look at what those test reports are really telling you, so you can make purchasing decisions with confidence.

How to choose the right LED downlight?

You're choosing between two downlights. Both have similar specs on paper, but one is much cheaper. It’s tempting, but you worry there's a hidden catch that will cause problems later.

To choose correctly, you must understand how those specs were generated. Scrutinize the testing conditions, especially temperature and stabilization time. A truly good downlight performs well in real-world conditions, not just in a perfectly controlled lab environment where data can be easily inflated.

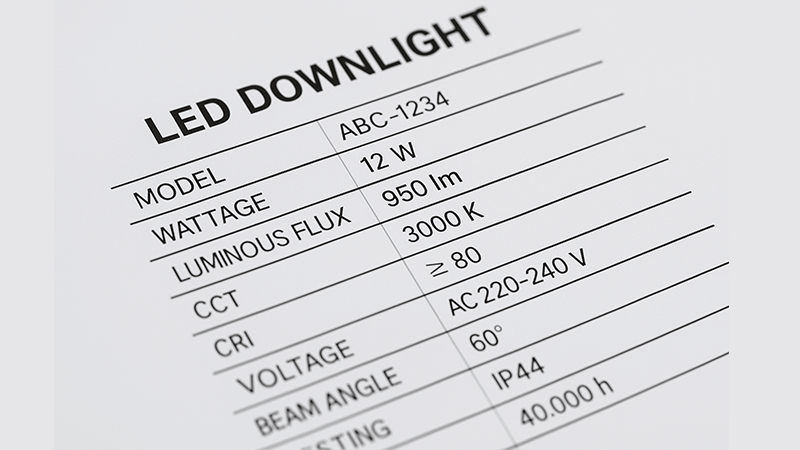

When you get a test report for a downlight, the most attractive numbers—lumen output1, efficacy2 (lumens per watt)—are almost always measured in an integrating sphere3. On the surface, this is the standard process. But the results depend entirely on the conditions inside that sphere. This is where the numbers can become misleading.

I remember visiting a supplier's lab years ago. They were showing me their testing process for a new downlight. The engineer placed the downlight on a metal plate that was actively being cooled. He proudly showed me the amazing efficacy numbers on the screen. The LED chip was at a perfect 25°C. I asked him, "Who has an air-conditioned ceiling void kept at 25°C?" He just smiled.

This is a common trick. LED chips are most efficient at a cool 25°C. But once you install that downlight in a hot, enclosed ceiling space, its temperature can easily rise to 60°C, 70°C, or even higher. At these temperatures, the efficiency can drop by 15-20% or more. The brilliant light you were promised becomes noticeably dimmer.

Another critical factor is stabilization time4. A quality test requires the lamp to be turned on for at least 30 minutes until its light output stabilizes. Some manufacturers, especially those using lower-quality components, will take a reading after just a few minutes. Why? Because they know their product suffers from rapid light decay, and a quick test hides this weakness.

So, when you look at a datasheet, you need to ask a few more questions.

Digging Deeper: From Lab Data to Real Performance

The pretty data on a report is often accompanied by a tiny line of text: "tested under specific laboratory conditions." This is the manufacturer's escape clause. Your job is to understand what those "specific conditions" were.

| Testing Parameter | "Optimized" Lab Condition | Realistic Installation Condition | Impact on Performance |

|---|---|---|---|

| Ambient Temperature | 25°C (often with external cooling) | 45°C+ in a sealed ceiling | 15-20% lower lumen output and efficacy. |

| Warm-up Time | 5 minutes or less | 30+ minutes for stabilization | Initial brightness is higher; hides poor thermal management and light decay. |

| Input Voltage | Perfect, stable 230V | Fluctuating voltage, common in many grids | Can stress the driver, leading to flicker or premature failure. |

Next time a supplier sends you a glowing test report, ask for the full details. What was the ambient testing temperature? How long was the lamp left on before measurements were taken? A good supplier will have this information and be transparent about it. A supplier who can't or won't answer is likely hiding something.

How many lumens is a standard downlight?

You need downlights for a project and are told a "standard" one is about 800 lumens. But you know lumens aren't the full story. You're worried about how long they will stay at 800 lumens.

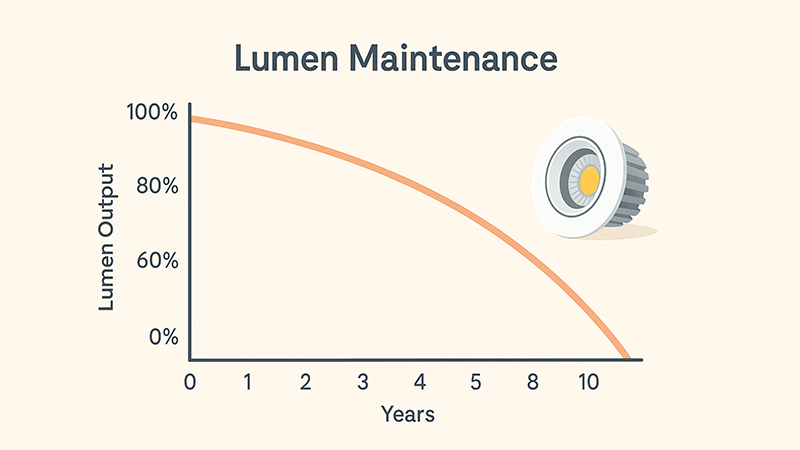

While 700-900 lumens is a common range for a standard residential downlight, the more important question is its lumen maintenance5. Look for the L-rating (e.g., L70 or L80) and the B-rating6 (e.g., B10 or B50) to understand how many lumens will be left after thousands of hours.

Let's talk about one of the biggest myths in the LED industry: the 50,000-hour lifespan. Many buyers see "50,000 hours" on a box and believe the light will work perfectly for over a decade. This is almost never true. That number is usually derived from an LM-80 report. An LM-80 report7 tests only the LED chip, not the entire fixture. It measures how long it takes for the chip to decay to 70% of its initial brightness (L70) under ideal, controlled laboratory temperatures.

A 50,000-hour lifespan claim is often just a marketing number. It completely ignores two of the most likely points of failure: the driver8 and the thermal management of the fixture itself.

I once worked with a client in the Emirates who was managing a large residential tower project. He had used downlights from another supplier that were advertised with a 50,000-hour life. After just three years, he was getting widespread complaints of flickering and failing lights. The LED chips were probably fine, but the drivers couldn't handle the heat and the electrical load. He had to replace thousands of fixtures, and the cost was enormous.

The driver is the heart of an LED fixture, and it's often the first component to fail, especially in high-heat environments. A high-quality driver from a reputable brand might be rated for 50,000 hours, but a cheap, no-name driver might fail in less than 10,000 hours. The fixture's design is also critical. If the heatsink9 can't effectively dissipate heat away from the chip and the driver, their lifespans will be drastically shortened, no matter what the LM-80 report says.

Digging Deeper: The True Lifespan of a Fixture

To understand a downlight's true lifespan, you have to look at it as a complete system. The lifespan is determined by its weakest link.

| Component | Marketing Claim (Often Based On) | Realistic Lifespan Determinant | What a Buyer Should Ask |

|---|---|---|---|

| LED Chip | 50,000+ hours (LM-80/TM-21 report) | Actual operating temperature inside the fixture. | "What is the L-rating at the expected operating temperature of the fixture?" |

| Driver | Often matches the LED chip's claimed life. | Component quality, operating temperature, and protection against voltage spikes. | "What brand is the driver, what is its warranty, and what is its temperature rating?" |

| Fixture/Housing | Rarely mentioned. | The heatsink's ability to dissipate heat away from the chip and driver. | "Can you provide thermal simulation data10 for this fixture in an enclosed ceiling?" |

Instead of just accepting a 50,000-hour claim, ask for the L-rating and the B-rating6. An L70 B50 rating at 50,000 hours means that after 50,000 hours, 50% of the lights in a batch will have fallen below 70% of their initial brightness. An L80 B10 rating is much better—only 10% of the lights will have fallen below 80% brightness. A reliable supplier should be able to provide this more detailed data. And always ask about the driver brand and its separate warranty11.

What to look for when buying spotlights?

You’ve received a sample spotlight that looks and performs perfectly. You’re ready to place a large order, but a nagging voice asks, "Will the 10,000 units I order be this good?"

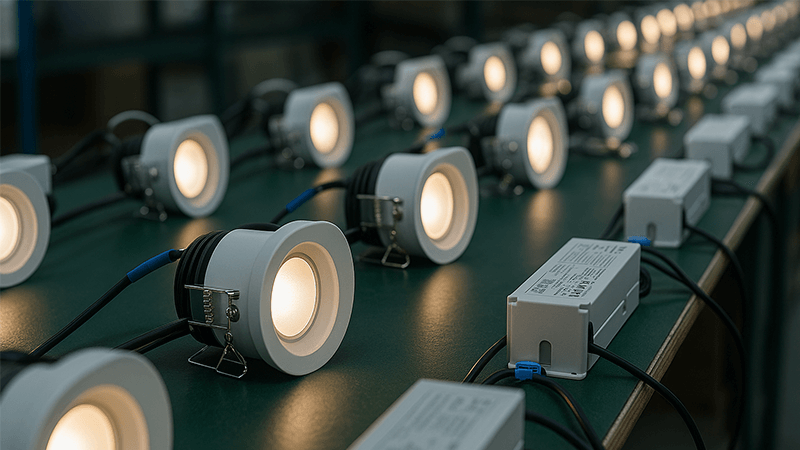

When buying spotlights or downlights, look for consistency between the approved sample and mass production. Ask the supplier about their quality control12 process for raw materials, production line assembly, and finished product testing to ensure every unit meets the same standard as the sample.

This brings us to the issue of the "golden sample." This is a very common practice, especially when dealing with new or unproven suppliers. You are sent a sample that has been hand-picked and specially crafted. The best LED chips are selected, the driver is from a top batch, and the assembly is done by the most skilled worker. It passes every test with flying colors. You approve it, place a huge order, and wait.

What arrives three months later is a different story. The fixtures look the same, but they use cheaper chips, a different batch of drivers, and the assembly quality is inconsistent. The performance is nowhere near the golden sample13 you approved.

I've seen this happen to even experienced buyers. It's a frustrating and costly problem. A friend of mine who works as a purchasing manager for a large distributor in Europe told me about a time he ordered 20,000 downlights based on a fantastic sample. When the shipment arrived, his team did spot checks and found that nearly 30% of the units had color consistency14 issues. The "golden sample" was a perfect 3000K, but the mass production units ranged from 2800K to 3300K. The supplier had used cheaper LED bins for the main order to save money.

Preventing this requires you to be proactive and look beyond the sample itself. You need to investigate the supplier's ability to produce quality at scale.

Digging Deeper: Ensuring Mass Production Quality

How can you be sure that the 10,000th unit is as good as the first? It comes down to vetting the supplier's quality control systems. A serious manufacturer will not be afraid to show you their processes.

Here are the key questions you should ask to protect yourself from the "golden sample" trap:

-

Incoming Quality Control (IQC):

- Question: "What is your process for testing incoming raw materials like LED chips and drivers?"

- What to look for: They should have dedicated equipment (like a small integrating sphere3) to test samples from every batch of LEDs for brightness and color consistency. They should be able to show you their testing records.

-

In-Process Quality Control (IPQC):

- Question: "How do you ensure consistency on the assembly line?"

- What to look for: Look for documented procedures, automated testing stations at key points in the assembly line (e.g., to check soldering and connections), and clear standards for workers.

-

Final Quality Control (FQC) & Aging Tests:

- Question: "What percentage of finished products do you test before shipping, and what does that test involve?"

- What to look for: A simple on-off test is not enough. Good factories perform a "burn-in" or "aging" test where a percentage of the lights are kept on for several hours (from 2 to 24 hours) to catch early failures. Ask what percentage of the batch they test and for how long.

A trustworthy partner will welcome these questions. They will see you as a knowledgeable and serious buyer. If a supplier is vague or dismissive, it's a major red flag that their processes can't stand up to scrutiny.

How much do LED downlights cost?

You see a wide range of prices for seemingly similar LED downlights. You need to justify your purchasing choice, but struggle to explain why a $15 downlight is a better long-term investment than a $5 one.

A good quality LED downlight for commercial projects can range from $10 to $30+. The price reflects the quality of the LED chip, driver, and thermal design. Cheaper downlights cut costs on these key components, leading to poor performance, shorter lifespans, and higher long-term costs.

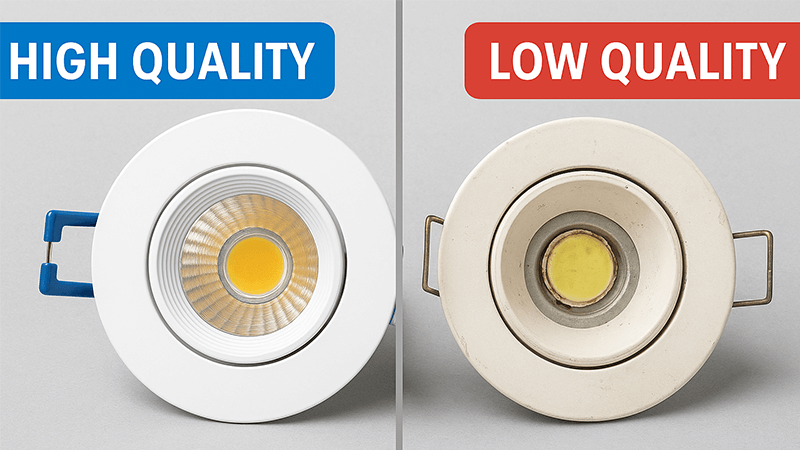

Price is always a factor, but in lighting, the initial purchase price is only a small part of the total cost of ownership. The cheapest option is almost always the most expensive in the long run. Why does one downlight cost $5 and another $15? The difference is inside. It's in the parts you can't see.

Let's break it down. I often explain to my partners that a downlight is a system made of three core elements: the light source (LED chip), the power source (driver), and the body (housing and heatsink). The final price is a direct result of the quality choices made for each of these three parts.

A supplier offering a rock-bottom price is making compromises. They might use an unknown brand of LED chip with poor color consistency, a low-cost driver with cheap capacitors that will fail in the heat, or an undersized aluminum heatsink that can't properly cool the electronics. These decisions save them a few dollars upfront, but they transfer all the risk to you and your client. The result is lights that change color, flicker, or simply die long before they should. Then you are left dealing with warranty claims, unhappy customers, and the high labor costs of replacement.

Digging Deeper: The True Cost of a "Cheap" Downlight

When you evaluate the cost, you must think about the total cost over the product's entire life. This includes the initial price, energy consumption15, and, most importantly, maintenance and replacement costs.

| Component | In a $5 "Cheap" Downlight | In a $15 "Quality" Downlight | Long-Term Cost Impact |

|---|---|---|---|

| LED Chip | Low-grade, un-binned, poor brand. Prone to color shifts. | High-quality, tightly binned chip from a brand like Cree, Lumileds, or Citizen. | Cheap chips look bad and fail early. Quality chips deliver consistent light for years. |

| Driver | Low-quality components, poor efficiency, no protections. | High-efficiency driver from a reputable brand (e.g., Philips, Tridonic, BOKE) with a 3-5 year warranty. | Cheap drivers are the #1 point of failure. The labor to replace a failed driver costs more than the entire quality fixture. |

| Heatsink | Thin, cast aluminum or even plastic. Poor thermal design. | Extruded or cold-forged aluminum with a large surface area. Excellent thermal dissipation. | Poor heat management kills the LED chip and driver, drastically shortening the product's life. |

| Warranty | 1 year (or difficult to claim). | 3-5 years, backed by a reputable company. | A good warranty is a sign of the manufacturer's confidence in their own product. |

Choosing the $15 downlight isn't an expense; it's an investment. You are paying for reliability. You are paying for peace of mind. You are protecting your reputation and ensuring your client's satisfaction for years to come. When you explain this to your own customers, you are no longer just selling a light; you are providing a reliable, long-term solution.

Conclusion

Look beyond the numbers on a test report. Ask about test conditions, demand production consistency, and understand that true cost is measured in years of reliable performance, not the initial price.

Understanding lumen output measurement helps you choose the right brightness for your space. ↩

Learn about efficacy to understand how efficiently your LED lights convert power into light. ↩

Discover how integrating spheres are used to measure light output accurately in controlled conditions. ↩

Understanding stabilization time helps you evaluate the reliability of LED performance data. ↩

Understanding lumen maintenance ensures you know how long your lights will perform at their rated output. ↩

Learn about B-ratings to assess the expected performance of LED lights over time. ↩

Learn about LM-80 reports to understand the longevity and performance of LED chips. ↩

Explore the importance of the driver in LED fixtures and how it affects performance and lifespan. ↩

Explore how heatsinks help manage heat in LED lights, ensuring better performance and longevity. ↩

Learn about thermal simulation data to assess the heat management capabilities of LED fixtures. ↩

Understanding warranty terms can help you choose reliable LED products with good support. ↩

Learn about quality control processes to ensure consistent performance in LED products. ↩

Understanding the concept of a golden sample can help you avoid quality issues in mass production. ↩

Learn about the importance of color consistency for achieving the desired ambiance in your space. ↩

Explore how energy consumption affects the overall cost-effectiveness of LED lighting solutions. ↩