Having trouble picking the right downlight for your project? The wrong fixture can compromise your design and budget. Understanding the key differences ensures you select the perfect lighting for any space.

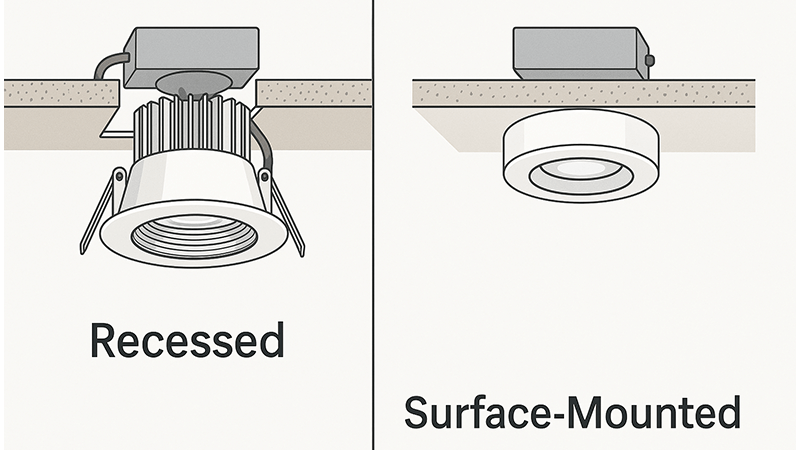

Recessed downlights are installed into a ceiling cavity for a flush, seamless look, requiring a cutout. Surface-mounted downlights attach directly onto the ceiling surface, making them ideal for solid ceilings like concrete where cutting holes isn't feasible. The main difference lies in their installation method.

This seems simple on the surface. But as a purchasing professional with over a decade of experience in this industry, I know the real differences go much deeper. It’s not just about where the light sits. It’s about performance1, long-term reliability2, and uncovering the hidden quality markers3 that separate a great product from a bad one. These details are what truly impact your project's success and your client's satisfaction. Let's look closer at what really matters when you're making this choice.

What is the difference between surface mounted and recessed downlights?

Your project needs downlights, but the ceiling type complicates the choice. Picking the wrong one means installation headaches, budget overruns, or a compromised design aesthetic, causing serious delays and client complaints.

Surface-mounted downlights4 are fixed directly onto the ceiling face, making them perfect for concrete slabs or when cutting holes is not an option. Recessed downlights5 are installed within a ceiling cavity for a clean, minimalist look. Your choice hinges on the ceiling structure6 and desired style.

When I started in this business, a client specified recessed downlights for an entire apartment complex. The problem? The ceilings were solid concrete. It was a huge oversight that nearly derailed the project timeline and budget. This experience taught me a valuable lesson: the first question must always be about the ceiling structure.

A recessed downlight requires a cavity above the ceiling plane. Think of drywall (plasterboard) ceilings or suspended grid ceilings. You need space to house the body of the fixture. In contrast, a surface-mounted downlight is the problem-solver for solid structures. It attaches directly to the surface, with its housing fully visible. This makes it a go-to choice for basements, garages, converted industrial spaces, and many modern buildings in regions like the UAE where concrete construction is standard.

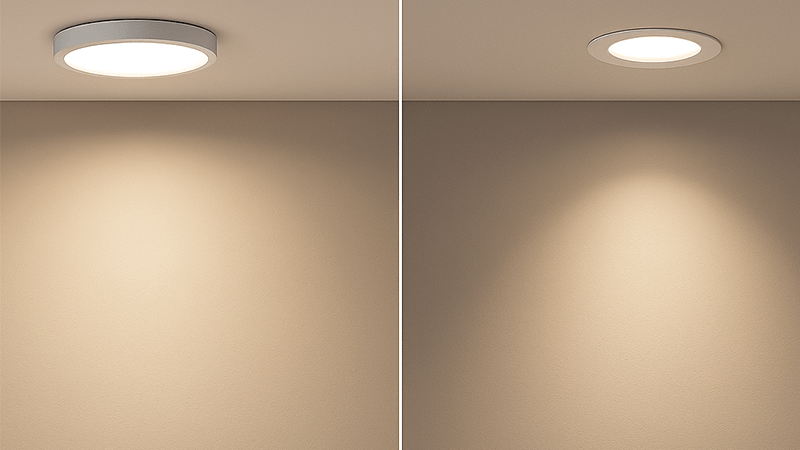

Beyond the technical necessity, the aesthetic impact7 is significant. Recessed lighting creates an unobtrusive, clean ceiling line, making the room feel larger and more modern. It puts the focus on the light itself, not the fixture. Surface-mounted fixtures are more pronounced. They become a part of the décor. You can choose minimalist cylinders for a modern look or more decorative styles8 to make a statement.

Here’s a quick breakdown for your reference:

| Feature | Recessed Downlight | Surface-Mounted Downlight |

|---|---|---|

| Best For | Hollow ceilings (drywall, suspended) | Solid ceilings (concrete, wood beams) |

| Installation | Requires cutting a hole, fixture sits inside ceiling | Bolts directly onto the ceiling surface |

| Aesthetic | Minimalist, seamless, hidden fixture | Visible fixture, acts as a design element |

| Common Use | General ambient lighting, modern homes, retail | Corridors, balconies, commercial spaces with concrete |

For a purchasing manager like Shaz, managing inventory for projects with mixed ceiling types is a common challenge. Sourcing both types from a single supplier who maintains a consistent design language and quality standard across their recessed and surface-mounted ranges can simplify procurement and ensure a cohesive look throughout the entire project.

What is the difference between surface mount and recessed mount?

The terms "surface mount" and "recessed mount" are used daily. However, subtle misunderstandings can lead to ordering completely wrong fixtures, causing costly delays and installation problems on-site.

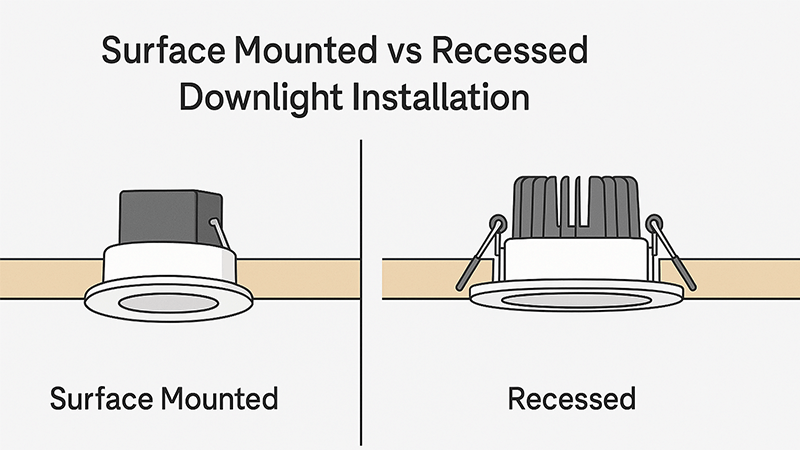

A recessed mount means the fixture's body is hidden above the ceiling plane, with only the trim visible. A surface mount means the entire fixture, including its housing, is attached onto and below the ceiling plane. The difference is whether the fixture is integrated into or onto the surface.

Let's move beyond the fixture and focus purely on the mounting method. This is where the engineering and installation practicalities come into play. As someone who has overseen production lines, the design of the mounting mechanism is critical for both the installer's ease and the fixture's long-term stability.

For a recessed mount, the primary mechanism is typically a set of spring-loaded clips9 or butterfly toggles. The installer pushes the fixture up through the cutout, and these springs flip out and clamp down onto the top of the ceiling board. A good spring system provides a firm, secure grip without damaging the drywall. A weak one can cause the fixture to sag over time. I've seen cheap fixtures with flimsy springs that a simple vibration can dislodge. For any serious project, you need robust, reliable spring clips.

A surface mount, on the other hand, relies on a mounting bracket10. This bracket is first screwed securely to the ceiling. The body of the downlight then attaches to this bracket, usually by twisting and locking into place or with small set screws. The key here is the bracket design. It must be strong enough to hold the fixture's weight and simple enough for a quick, secure installation. A poorly designed bracket can make installation frustrating and time-consuming.

Now, I want to share a critical insight that many overlook: the quality of the heatsink11. A heavier-feeling downlight of the same size is often a good sign. Why? Because the heatsink, which is essential for the LED's lifespan, is typically made of aluminum. A heavier heatsink usually means it's made from thicker, more substantial aluminum, which is better at dissipating heat. I once compared two similar-looking downlights. One was noticeably lighter. When we cut it open, the "heatsink" on the lighter one was just a thin, flimsy piece of pressed metal—a clear case of cutting corners that would lead to premature failure. Always check the weight and feel of the heatsink; it's a simple but effective test of quality.

What is the difference between surface lights and recessed lights?

You see "surface light" and "recessed light" on spec sheets, but what's the real impact on lighting design? Choosing the wrong one can ruin the intended atmosphere and functionality of a space.

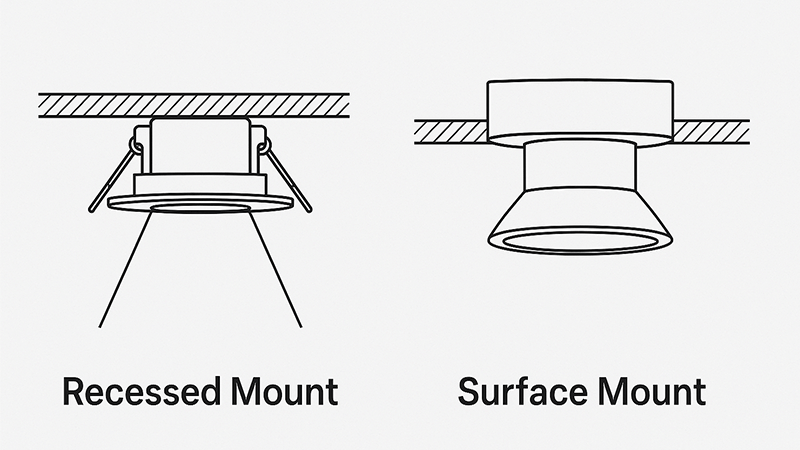

Recessed lights provide a focused, often downward-facing beam from a hidden source, creating pools of light and a clean ceiling. Surface lights, being visible fixtures, can offer broader, more diffuse illumination and also contribute to the room's visual style. The key difference is in light distribution and visual presence.

Let’s talk about what the light actually does in the room. This is where the choice between a recessed and surface fixture moves from a construction decision to a design one. A recessed light is the workhorse of modern lighting design. It's perfect for creating layers of light. You can use it for:

- General Lighting: Spaced evenly across a ceiling to provide overall ambient light.

- Task Lighting: Positioned directly over a kitchen counter, a desk, or a reading chair.

- Accent Lighting: Using adjustable "gimbal" versions to highlight artwork or architectural features.

The magic of recessed lighting is its subtlety. The source is hidden, so you see the effect—a bright workspace, a highlighted wall—without being distracted by the fixture itself.

Surface lights, because they are visible, have a different role. While a simple cylindrical surface downlight can perform a similar function to a recessed one, many surface fixtures are designed to do more. They can be larger, feature decorative elements, or use diffusers that soften the light and distribute it more broadly. This makes them excellent for areas where you want a gentle, even glow rather than focused beams, such as hallways, closets, or utility areas. Their physical presence also means they must align with the room's aesthetic. A sleek, black cylinder fits a minimalist or industrial space, while a fixture with brass or wood accents might suit a different style entirely.

Here's an inside tip on color rendering12. Many suppliers will claim a high CRI13, like Ra>90. This sounds great, but it can be misleading. The standard CRI test (R1-R8) doesn't include saturated red (R9). A low R9 value is why food, wood tones, and even skin can look dull and unnatural, even under a "high CRI" light. When I source for a high-end project, I always ask for the R9 value. For spaces where color accuracy is paramount, like retail stores or kitchens, a high R9 value (ideally >50) is non-negotiable. It’s a detail that separates truly high-quality light from the rest.

What is the difference between an LED downlight and a recessed light?

Are you sourcing "LED downlights" or "recessed lights"? Using these terms interchangeably can lead to confusion and incorrect product specifications, especially when dealing with different international suppliers.

"Recessed light" describes the installation style—a fixture installed flush into the ceiling. "LED downlight" describes the technology and function—a down-firing light source that uses an LED. A light can be both, like an "LED recessed downlight," which is the modern standard.

This distinction often causes confusion, but it’s quite simple when you break it down. Think of it like this:

- Recessed Light: This is the category of the housing, the physical can or fixture that gets installed into a ceiling. Historically, these housings could hold any type of bulb—incandescent, halogen, or CFL. The term simply describes the form factor.

- LED Downlight: This refers to a light fixture designed specifically for an LED source that directs light downwards. It can be a recessed model, a surface-mounted model, or even a track-mounted model.

In today's market, the two have merged. When we say "recessed light," we almost always mean an "integrated LED recessed downlight." The LED engine is built directly into the fixture. This is far more efficient and compact than the old style of putting a separate LED bulb into a large recessed can. The integrated design allows for better thermal management, which is crucial for the LED's lifespan and performance1. The heatsink is designed specifically for that LED chip, ensuring it runs cool and maintains its brightness and color quality for years.

This brings me to another critical point: flicker. Many products claim to be "flicker-free14." In reality, truly zero flicker is almost impossible. The real term is "no visible flicker." The danger lies in cheap, low-quality drivers. They might not produce a flicker you can see with your naked eye, but the high-frequency flicker they emit can still cause eye strain, headaches, and fatigue over time. This is measured by "flicker depth" or "percent flicker." For any project where people will spend significant time under the lights, like an office or school, I insist on drivers with very low flicker percentages. It's an invisible mark of quality that has a very real impact on human well-being.

Finally, a note on the encapsulating glue used to cover the LED chips. In our factory, we only use silicone. It's stable at high temperatures and doesn't yellow, ensuring the light quality remains consistent. Many lower-cost factories use epoxy resin. It's cheaper, but it yellows quickly under heat, causing the light color to shift and the brightness to fade rapidly. This is what we call light decay15, and it's a sure sign of a low-quality product.

Conclusion

In short, recessed lights install into the ceiling for a minimal look, while surface-mounted lights attach onto it. Your choice depends on ceiling type, but true quality lies in hidden details.

Understand the importance of performance in selecting the right downlights for your project. ↩

Find out how to ensure the longevity and reliability of your lighting fixtures. ↩

Identify key quality indicators that separate high-quality downlights from inferior options. ↩

Learn about the unique features and applications of surface-mounted downlights in various settings. ↩

Explore the advantages of recessed downlights for modern lighting solutions and design aesthetics. ↩

Learn how different ceiling types affect the choice of downlights for your project. ↩

Explore how different downlight styles can enhance the overall design of a space. ↩

Learn about various decorative options available for surface-mounted downlights. ↩

Understand the function of spring-loaded clips in ensuring secure installation of recessed lights. ↩

Learn about the importance of a sturdy mounting bracket for surface-mounted fixtures. ↩

Discover the role of heatsinks in maintaining LED performance and longevity. ↩

Explore the significance of color rendering in achieving accurate and vibrant lighting. ↩

Understand the significance of high CRI values for achieving true color accuracy. ↩

Understand the implications of flicker-free technology for eye comfort and lighting quality. ↩

Learn about the factors that contribute to light decay and how to avoid it. ↩