Buying IP44 downlights1 feels complicated with all the different certifications2. This confusion can lead to safety risks or failed inspections, but it doesn’t have to.

For IP44 LED downlights, buyers should look for certifications relevant to the sales region, such as UL/ETL for North America or CE for Europe. Also, check for RoHS for material safety and an IC rating if the lights will touch insulation. These ensure safety, compliance, and quality.

Understanding these certifications is not just about ticking a box. It's about ensuring the product you source is safe, reliable, and legal for your specific market. As a manufacturer, I know that obtaining these certifications is a serious commitment to quality. For a purchasing manager like Shaz, knowing what to look for is the first step in sourcing a product that won't cause problems down the line. It protects your project, your client, and your reputation. Let's break down what these labels really mean for you.

Do LED lights need CSA approval3?

You're trying to sell lights into Canada but are unsure about CSA rules. Ignoring this could mean your products get rejected, causing costly delays and damaging your reputation.

Yes, most electrical products sold or installed in Canada, including LED lights, must be certified by a recognized body. This is often the CSA (Canadian Standards Association) mark, or an equivalent like cUL or cETL4, to prove they meet Canadian electrical safety standards.

In my years of manufacturing, I've learned that market-specific certifications are non-negotiable. The Canadian market is a perfect example. The CSA mark, or its equivalents, tells inspectors, electricians, and customers that a product has been independently tested and meets the strict safety standards outlined in the Canadian Electrical Code. Without it, an electrician simply will not install the fixture. It's a huge liability for them.

I remember working with a new distributor based in Vancouver. They loved one of our IP44 downlight designs but had one critical question before placing an order: "Is it cUL5 or CSA certified?" They didn't ask about lumens or color temperature first; they asked about compliance. For them, it was the gatekeeper. If the answer was no, the conversation was over.

For a purchasing manager, this is crucial. You need to know the marks that are accepted.

Understanding Canadian Certification Marks

| Mark | Organization | Meaning |

|---|---|---|

| CSA | Canadian Standards Association | The product is tested and certified by CSA Group to meet Canadian standards. |

| cUL | Underwriters Laboratories | The product is tested by UL to meet Canadian standards. The small "c" is critical. |

| cETL | Intertek | The product is tested by Intertek to meet Canadian standards. Again, the "c" indicates Canadian compliance. |

These three marks are functionally equivalent in the eyes of Canadian authorities. As a buyer, seeing any of them on a product spec sheet means you're cleared for the Canadian market. This commitment to testing shows that the manufacturer, like my company iPHD, is dedicated to producing safe and reliable products.

What is a lighting certificate?

You see a list of letters on a product sheet: CE6, UL, RoHS7, DLC8. It feels like an alphabet soup, and you are not sure which ones are important for your market.

A lighting certificate9 is an official document from an independent organization. It proves a light fixture has been tested and meets specific standards for safety, performance, or material safety for a particular region. For example, the UL mark is for safety in the US.

Think of certifications as a product's passport. They show that a product is allowed to enter and be sold in a specific country or region. They are independent proof that what the manufacturer claims is true. We can’t just say our products are safe; we have to prove it through rigorous third-party testing. For a buyer, these certificates are a vital tool for managing risk and ensuring quality. They fall into a few main categories.

Key Certification Categories

1. Safety Certifications These are usually mandatory and are the most important. They verify that a product will not cause electric shock or fire under normal use.

- UL/ETL10 (North America): These marks from Underwriters Laboratories (UL) or Intertek (ETL) mean the product meets US and/or Canadian safety standards. They involve rigorous product testing and regular factory inspections to ensure ongoing compliance.

- CE (European Union): The CE mark is a manufacturer's declaration that the product meets EU standards for health, safety, and environmental protection. For lighting, this typically means complying with the Low Voltage Directive (LVD) and EMC Directive. While it's a self-declaration, reputable manufacturers back it up with full testing reports from a lab.

2. Environmental & Material Safety Certifications These relate to the materials used in the product.

- RoHS (Restriction of Hazardous Substances): Originally from the EU, this is now a global standard. It restricts the use of six hazardous materials, including lead and mercury, in electronics. I had a client in Germany who needed full RoHS compliance reports for every tiny component. It was a lot of work, but it showed our commitment and built tremendous trust.

3. Performance Certifications These are often voluntary but indicate high efficiency and quality.

- Energy Star11 / DLC (North America): Energy Star is for consumer products, while DLC (DesignLights Consortium) is for commercial lighting. Products with these labels are highly energy-efficient and may qualify projects for government or utility rebates, which is a great selling point.

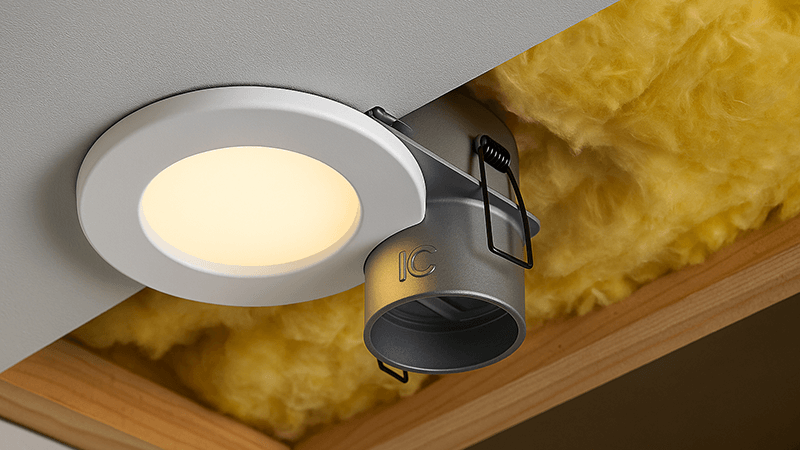

Do LED recessed lights12 need to be IC rated?

You are choosing recessed lights for a ceiling filled with insulation. Using the wrong type of fixture could lead to overheating, creating a serious and hidden fire hazard.

Yes, if a recessed light will physically touch thermal insulation13 in the ceiling, it absolutely must be IC-rated. The "IC" stands for "Insulation Contact," and this rating ensures the fixture is designed to operate safely without overheating when covered by insulation.

I can't stress this enough: the IC rating14 is a critical safety feature, not an optional upgrade. Even though modern LED downlights are very efficient and run cooler than old halogen bulbs, the driver and internal electronics still produce heat. If that heat gets trapped by insulation around a fixture not designed for it, the temperature can build up to dangerous levels, posing a significant fire risk. An IC-rated fixture is built with a housing or design that allows it to dissipate heat properly, even when completely buried in insulation.

This is especially relevant for IP44 downlights. These are often used in bathrooms or under eaves and hallway entrances where you might bring in a wet umbrella. These spaces frequently have insulated ceilings to improve a building's energy efficiency. Therefore, a fixture for this application often needs to be both IP44 and IC-rated.

I always advise contractors and buyers to confirm the installation environment. Ask the question: "Will the fixtures be in contact with insulation?"

IC-Rated vs. Non-IC-Rated Downlights

| Feature | IC-Rated Downlight | Non-IC Rated Downlight |

|---|---|---|

| Contact with Insulation | Can be in direct contact | Requires clearance (usually 3 inches) |

| Safety | Designed to prevent overheating when covered | Can be a fire hazard if covered by insulation |

| Installation | Can be installed in any insulated or uninsulated ceiling | Only for uninsulated ceilings or where clearance can be maintained |

| Best Use Case | Insulated ceilings, new construction, energy-efficient homes | Uninsulated ceilings, dropped ceilings, remodeling projects |

Choosing a non-IC light for an insulated ceiling is not just a building code15 violation; it's a gamble with safety. As a reliable supplier, we make it a point to offer clearly labeled IC-rated options and educate our partners on when to use them.

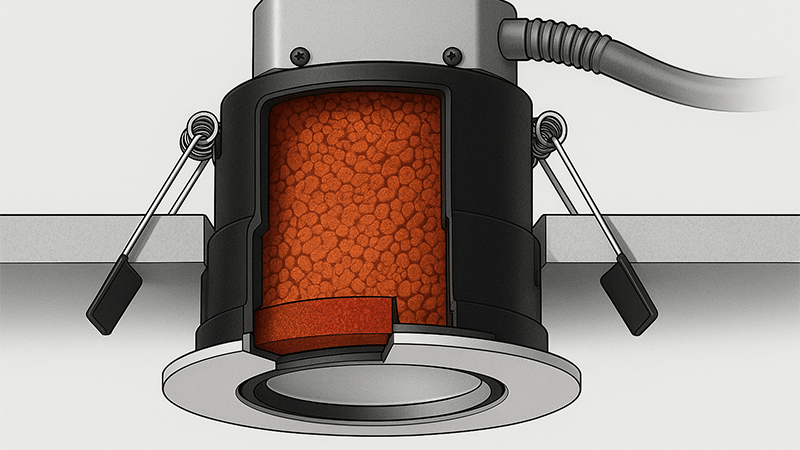

How to tell if downlights are fire rated LED16?

You need to maintain the fire barrier of a ceiling in a multi-story building. Cutting a hole for a standard downlight breaks that barrier, violating codes and compromising safety.

Look at the product's official specification sheet, packaging, or the body of the fixture itself for a fire rating. This rating will be given in minutes (e.g., 30, 60, 90 minutes) and should also state compliance with a specific standard, like BS 476 for the UK.

A fire-rated downlight performs a critical, life-saving function. When you cut a hole in a fire-rated ceiling (a ceiling designed to stop fire from spreading for a certain period), you create a weak spot. A fire-rated downlight is engineered to restore the ceiling's integrity. It contains a special material called an intumescent strip. In a fire, the heat causes this material to swell up dramatically, completely sealing the hole left by the downlight. This action stops fire and smoke from rushing into the floor above, giving people more time to escape.

It’s important to understand this is different from an IC rating.

- IC Rating: Prevents a fire from starting due to the light overheating in insulation.

- Fire Rating: Prevents an existing fire from spreading from one floor to the next through the hole cut for the light.

A downlight can have one, both, or neither of these ratings. The choice depends on the building code and where the light will be installed. For example, in a multi-family apartment17 building in the UK, fire-rated downlights are almost always required between floors.

The fire rating in minutes (30, 60, 90) must match or exceed the rating of the ceiling. A 60-minute ceiling requires a 60-minute (or 90-minute) rated downlight. The testing process for these products is intense; we literally place them in a furnace to prove they work. When a buyer like Shaz sources a fire-rated downlight from my factory, he is providing a tested, certified safety device that protects both property and lives.

Conclusion

Choosing the right IP44 downlight goes beyond its water resistance. You must check for safety and regional certifications like UL, CE, and CSA to ensure compliance and a successful project.

Explore the advantages of IP44 downlights for your lighting needs and ensure you make an informed choice. ↩

Understanding certifications can help you choose safe and compliant lighting products for your projects. ↩

Explore the necessity of CSA approval for LED lights sold in Canada to avoid costly delays. ↩

Discover the meaning of cETL certification and its role in ensuring product safety in Canada. ↩

Learn about cUL certification and its importance for compliance with Canadian safety standards. ↩

Discover the significance of the CE mark and how it ensures compliance with EU safety standards. ↩

Find out how RoHS compliance affects the safety and environmental impact of lighting products. ↩

Learn about DLC certification and its benefits for energy-efficient commercial lighting. ↩

Understand the role of lighting certificates in verifying product safety and performance. ↩

Learn about UL/ETL certifications to ensure your lighting products meet safety standards. ↩

Explore how Energy Star certification can help you choose energy-efficient lighting solutions. ↩

Explore the advantages of LED recessed lights for energy efficiency and modern design. ↩

Understand the significance of thermal insulation in preventing fire hazards with recessed lights. ↩

Understand the importance of IC ratings for safe installation of recessed lights in insulated ceilings. ↩

Explore building code requirements to ensure compliance and safety in your lighting installations. ↩

Find out how to identify fire rated LED downlights to ensure safety in multi-story buildings. ↩

Learn about specific lighting requirements for multi-family apartments to ensure safety and compliance. ↩