Struggling to find reliable downlights for a huge project? The wrong choice means high costs and frequent failures. The best value comes from focusing on thermal management and component quality.

The best value COB LED downlights for large deployments have excellent thermal management (total thermal resistance ≤3 K/W), high-quality drivers, and reliable chips from reputable brands. These factors ensure long lifespan, consistent performance, and low maintenance costs, maximizing your return on investment.

Getting the best value is more than just the initial price. It's about understanding the specific features that make a downlight last and perform well over time. In my experience helping clients like Shaz source for massive projects, focusing on the technical details is what separates a successful deployment from a costly failure. To make the right choice, you need to look at several key factors. Let's break down what really matters when you're sourcing these lights.

Which color COB light is best?

Worried about the lighting color creating the wrong mood? A poor choice can make a space feel unwelcoming. The best color depends entirely on the application and desired atmosphere.

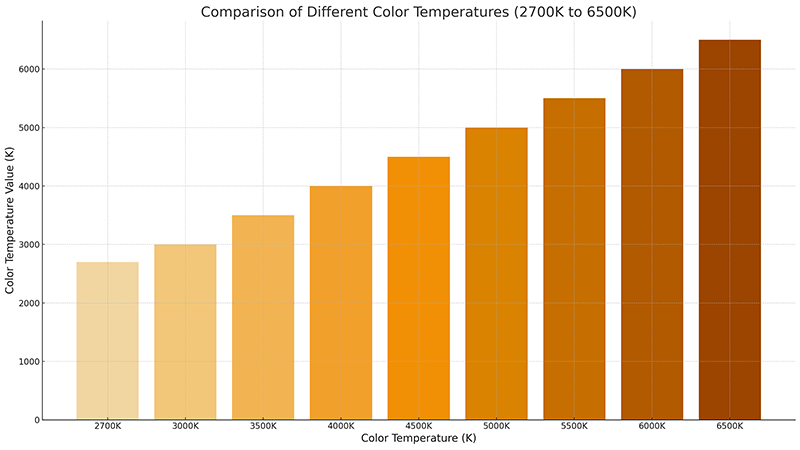

There is no single "best" color. For homes and hospitality, warm white (2700K-3000K)1 is popular. For offices and retail, neutral white (4000K)2 is common. For task-oriented or industrial areas, cool white (5000K-6500K)3 is often used. Always choose based on the specific environment.

Choosing the right color is about more than just personal preference; it's a science that impacts mood and functionality. As a manufacturer, I guide my partners through two critical metrics: Color Temperature (CCT)4 and Color Rendering Index (CRI)5.

Understanding Color Temperature (CCT)

CCT is measured in Kelvin (K) and describes how "warm" or "cool" the light appears. Lower numbers mean warmer, more yellowish light, while higher numbers mean cooler, bluer light.

- Warm White (2700K-3000K): Creates a cozy, relaxing atmosphere. It’s perfect for hotels, restaurants, and homes.

- Neutral White (4000K): A clear, clean light that is great for focus and productivity. We see this used most often in offices, schools, and modern retail spaces.

- Cool White (5000K-6500K): Mimics daylight and is very bright. This is best for warehouses, hospitals, and any area where high visibility for detailed tasks is critical.

The Importance of Color Rendering Index (CRI)

CRI measures how accurately a light source reveals the true colors of objects, on a scale of 0 to 100. For most commercial projects, a CRI of 80+ is acceptable. But in some cases, it's the most important factor. I remember working with a client on a high-end fashion boutique. They initially chose 4000K lights with a standard 80 CRI, and the clothes looked a bit dull. We swapped them for 3500K lights with a 95 CRI. The difference was incredible. The rich colors on the fabrics instantly popped. The client was thrilled because customers could see the true quality of the garments.

Matching Color to Application

To make it simple for purchasing managers, I've created this basic guide. This is the same advice I give to my direct partners.

| Application | Recommended CCT | Recommended CRI | Why? |

|---|---|---|---|

| Hospitality | 2700K - 3000K | 80+ | Creates a welcoming, comfortable feel for guests. |

| Office/Commercial | 4000K | 80+ | Promotes alertness and focus without being harsh. |

| High-End Retail | 3000K - 4000K | 90+ | Makes product colors look vibrant and true to life. |

| Industrial/Warehouse | 5000K | 80+ | Maximizes visibility for safety and accuracy. |

Which is better HPS or COB LED?

Are you still relying on old HPS lighting technology? You're likely facing high energy costs and frequent bulb replacements. COB LEDs offer a far superior, modern solution for efficiency.

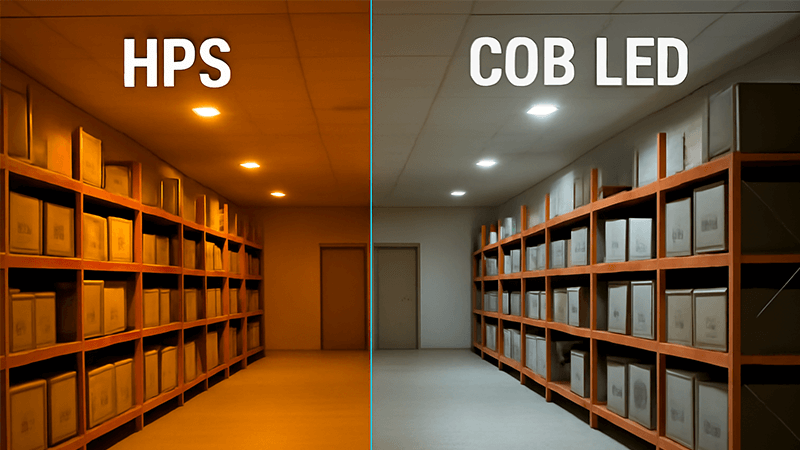

COB LED is significantly better than High-Pressure Sodium (HPS)6. LEDs offer superior energy efficiency7, much longer lifespan, better color rendering (CRI), and instant-on capability. HPS is only cheaper upfront but costs far more in energy and maintenance over the long run.

For many years, HPS was the standard for large-area lighting like streets and warehouses. But technology has moved on. When I talk to project managers about retrofitting old facilities, the comparison is always a simple one. The long-term value of COB LED is undeniable.

The Direct Comparison: Efficiency and Lifespan

COB LEDs are champions of efficiency. A typical COB LED can produce over 130 lumens per watt (lm/W), while an HPS lamp often struggles to reach 100 lm/W, and this number gets worse over its short life. This means for the same amount of light, LEDs use significantly less electricity. Then there's lifespan. An HPS lamp might last 24,000 hours, but a quality COB LED fixture is rated for 50,000 hours or more. That means less than half the maintenance, which is a huge labor saving on large-scale deployments.

Light Quality and Control

This is where the difference is most obvious. HPS lights produce a very poor quality, monochromatic orange light, with a CRI of around 25. This makes it very difficult to distinguish colors. COB LEDs, as we discussed, can provide light with a CRI of 80 or 90+, making everything look clear and natural. Additionally, LEDs are "instant-on" and can be easily dimmed. HPS lamps need several minutes to warm up to full brightness and are difficult and expensive to dim.

Total Cost of Ownership

A purchasing manager like Shaz is always focused on the total cost. HPS fixtures might seem cheaper at first, but it's a trap. A TCO calculation always tells the true story. I once worked with a warehouse manager who was hesitant about the upfront cost of switching from HPS. We did a calculation for just one section of his facility. The energy savings alone paid for the new COB LED high bays in under 18 months. Beyond that, his maintenance team was freed up from constantly replacing bulbs, and his picking staff reported fewer errors because they could finally read labels easily.

| Feature | High-Pressure Sodium (HPS) | COB LED | The Clear Winner |

|---|---|---|---|

| Efficacy | 60-110 lm/W | 120-170+ lm/W | COB LED |

| Lifespan | ~24,000 hours | 50,000+ hours | COB LED |

| CRI | 20-30 (Very Poor) | 80-95+ (Excellent) | COB LED |

| Warm-up Time | 5-10 Minutes | Instant | COB LED |

| Energy Use | High | Very Low | COB LED |

| Maintenance | Frequent | Minimal | COB LED |

What to consider when buying downlights?

Feeling lost in a sea of technical data for downlights? Picking the cheapest option is a recipe for disaster. Let's focus on the crucial factors that guarantee performance and longevity.

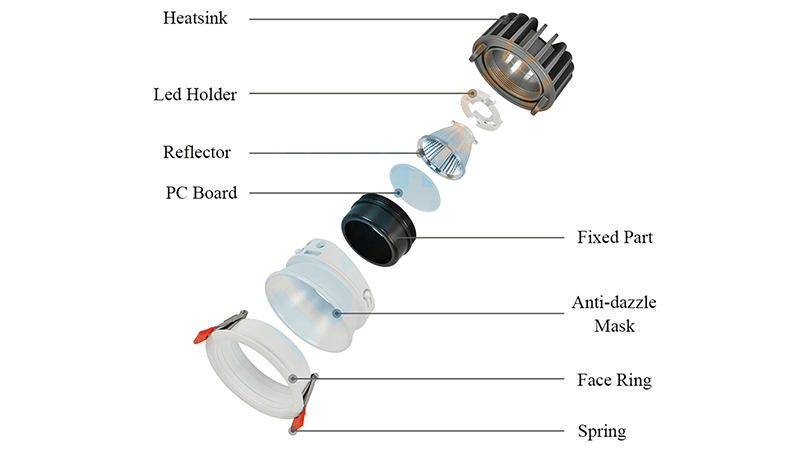

When buying downlights, prioritize thermal management8 (heat sink quality), the LED driver (lifespan and efficiency), the chip brand (reliability), and certifications (safety). For large projects, also consider beam angle9, CCT, CRI, and the manufacturer's warranty.

When you are responsible for sourcing thousands of light fixtures, you can't afford failures. A bad batch can ruin a project's timeline and budget. Over my years building this business, I've seen exactly what makes a downlight last. It comes down to a few core components that you must inspect closely.

Thermal Management: The Most Critical Factor

Heat is the number one enemy of an LED. If a downlight can't get rid of the heat it generates, its performance and lifespan will drop quickly. This is where I share my most important rule with my partners: the total thermal resistance of the entire lamp must be ≤3 K/W. This number tells you how efficiently the lamp moves heat away from the sensitive LED chip10. A lower number is better. To achieve this, a lamp needs a heavy, well-designed heat sink, usually made of cold-forged aluminum. When you pick up a quality downlight, it should feel substantial and heavy. A light, flimsy heat sink is a sure sign of a cheap product that will fail.

The Driver: The Heart of the Lamp

The driver is a small power supply inside the fixture that converts AC power from the wall into the low-voltage DC power that the LED needs. A cheap driver is another common point of failure. It can cause flickering, have low power efficiency (wasting energy), and will often die long before the LED chip itself. For large, important projects, I always recommend using fixtures with drivers from reputable brands like Philips, Tridonic, or Lifud. The small extra cost for a good driver is an investment in reliability.

Chip, Optics, and Certifications

The COB chip itself is what produces the light. Sourcing from manufacturers who use chips from established brands like Citizen, Cree, or Bridgelux adds another layer of security. Pay attention to the beam angle—a narrower angle (e.g., 24°) is good for high ceilings or accent lighting, while a wider angle (e.g., 60°) is better for general illumination in rooms with standard ceilings. Finally, always check for safety and performance certifications like CE, RoHS, and UL. These prove the product has been tested and meets international standards.

| Factor | What to Look For | Why It Matters |

|---|---|---|

| Thermal Resistance | Must be ≤3 K/W | Guarantees long life and stable light output. |

| Heat Sink | Heavy, cold-forged aluminum | Effectively dissipates heat away from the chip. |

| LED Driver | Reputable brand, >0.9 Power Factor | Ensures reliability and energy efficiency. |

| LED Chip | Reputable brand (Citizen, Cree, etc.) | Provides consistent light quality11 and performance. |

| Warranty | Minimum 3-5 years | Shows the manufacturer's confidence in their product. |

Why are COB LEDs yellow?

Have you noticed that your COB LEDs have a yellow coating when they are off? It might look odd, but it's not a flaw. This yellow layer is a critical piece of technology.

COB LEDs appear yellow because they are coated with a layer of phosphor. The actual LED chip underneath produces blue light. This blue light excites the phosphor, which then converts some of that light to create the final white light we see.

This is one of the most common questions I get, and the answer lies deep in the science of how we create high-quality, efficient white light. Understanding this process also reveals why quality control in manufacturing is so important.

The Science of Phosphor Conversion

The most efficient way to generate light from a semiconductor is by producing blue light. All white LEDs start their life as a tiny, powerful blue LED die. But for general lighting, we need white light, not blue. This is where the yellow layer comes in. That layer is a carefully engineered chemical compound called phosphor. When the blue light from the LED die passes through the phosphor, the phosphor gets excited and glows, emitting light in the yellow and red parts of the spectrum. This new yellow light mixes with the remaining blue light that passes through, and our eyes perceive the combination as white light.

How Phosphor Determines Color Temperature

The fascinating part is how we control the "color" of the white light. It's all about the phosphor.

- For a "warm white" light (2700K): We apply a thicker, denser layer of phosphor. This converts more of the blue light into yellow light, resulting in a warmer, cozier final color.

- For a "cool white" light (5000K): We apply a much thinner layer of phosphor. This allows more of the original blue light to pass through, mixing with less yellow light to create a cooler, bluer-white light. So, the yellow appearance you see is directly related to the final CCT of the lamp. A 3000K COB will look more orange-yellow than a 5000K COB when turned off.

Quality Control in Phosphor Application

This process highlights why manufacturing precision12 is key. For a large project with thousands of downlights, you need every single one to have the exact same color. Even a tiny variation in the thickness or chemical mix of the phosphor from one chip to the next can cause a noticeable difference in light color. At iPHD, we are obsessed with color consistency13. We use strict binning processes, like MacAdam ellipses, to ensure that all the chips in a single order come from the same batch and have virtually identical color properties. This prevents a "checkerboard" effect on the ceiling and guarantees a professional, uniform look across an entire project.

Conclusion

For large deployments, value isn't the upfront price. It's found in superior thermal design, quality components, and correct color specs. This ensures reliability and long-term savings.

Find out why warm white lighting is preferred in hospitality and home settings. ↩

Learn about the applications of neutral white lighting in offices and commercial spaces. ↩

Discover the benefits of cool white lighting in industrial and task-oriented areas. ↩

Understanding CCT helps in selecting the right lighting for different environments and moods. ↩

Explore how CRI affects the appearance of colors under different lighting conditions. ↩

Understand why HPS lighting is being replaced by more efficient technologies like LEDs. ↩

Explore the importance of energy efficiency in reducing long-term costs and environmental impact. ↩

Understanding thermal management is crucial for ensuring the longevity and performance of LED downlights. ↩

Understanding beam angle is essential for achieving the desired illumination in a space. ↩

Discover the key factors that determine the quality and performance of LED chips. ↩

Explore the various factors that contribute to the overall quality of LED lighting. ↩

Learn why precision in manufacturing is crucial for maintaining high-quality LED products. ↩

Discover how color consistency impacts the overall aesthetic and functionality of lighting. ↩