Having issues with LED downlights that flicker or burn out quickly? The hidden cause is often a low-quality driver, making it hard to choose a reliable product for your project.

The best drivers for LED downlights are isolated, constant-current models that use high-quality IC chips. This technology provides stable power, protects the LED, eliminates flicker, and ensures a long, reliable lifespan. It's the standard for any professional project where quality and performance are critical.

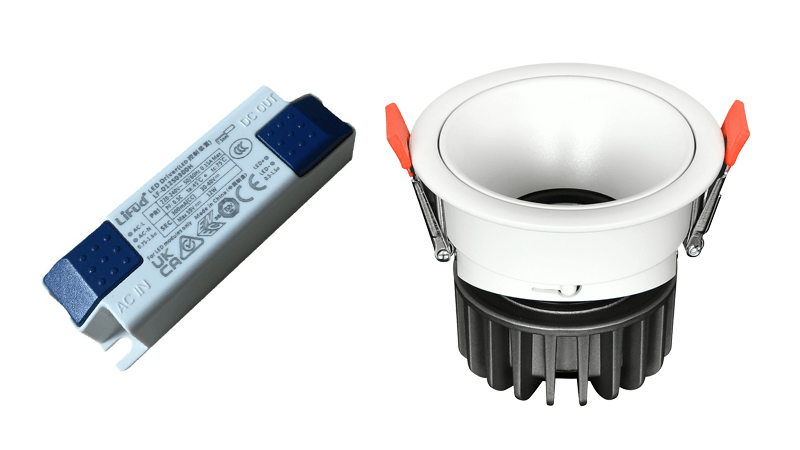

The driver is the heart of any LED downlight. It takes the high voltage from your wall and converts it into the low, stable voltage that the LEDs need to work. When I first started in this industry, I saw firsthand how a cheap driver1 could ruin an otherwise good product. A client of mine, a purchasing manager named Shaz, learned this the hard way when a batch of downlights started failing just months after installation. The problem wasn't the LED chip; it was the cheap driver inside. To avoid these expensive mistakes, you need to understand what separates a good driver from a bad one. Let's dig into the details so you can choose with confidence.

Do LED downlights need drivers?

Your project specifications call for LED downlights2, but do they all need a separate driver? This confusion can lead to installing lights that are inefficient, unsafe, or simply don't last.

Yes, almost all LED downlights require a driver. The driver converts high-voltage alternating current (AC) from the mains supply into the low-voltage direct current (DC) that LED chips need to operate. Without a driver, the LEDs would burn out instantly when connected directly to the power source.

When I walk through factories, I see the core reason LED downlights need drivers. LEDs are semiconductors, and they are very sensitive to the power they receive. The electricity in our buildings is high-voltage AC (Alternating Current), usually 120V or 240V. LEDs, however, run on low-voltage DC (Direct Current). A driver acts as the translator between these two worlds. It's not just a simple power converter; a good driver manages the flow of electricity to protect the sensitive LED chips3. It provides a constant, steady current, which prevents the LEDs from overheating and degrading quickly.

Think of it like this: you can't plug a delicate electronic device directly into a massive power station. You need a series of transformers and regulators to make the power safe and usable. An LED driver does that same job, but on a much smaller scale, right inside or alongside your light fixture. Some cheap products try to use very simple, poor-quality circuits instead of a proper driver, which leads to major problems. A proper driver is absolutely essential for safety, performance, and giving the downlight a long life. It is the single most important component for reliability.

What driver do I need for my LED lights?

You know you need a driver, but the options are overwhelming. Choosing the wrong type can cause flicker4ing, poor performance, and even safety hazards, putting your project and reputation at risk.

You need a constant-current LED driver that matches the voltage and current requirements of your LED downlight. For the best performance and safety, always choose an "isolated" driver over a "non-isolated" one, as it provides a crucial safety barrier between the high-voltage input and low-voltage output.

The most important choice you'll make is between an isolated and a non-isolated driver5. In my experience, this is where many manufacturers cut corners to reduce costs. A non-isolated driver has a direct electrical connection between the high-voltage input side and the low-voltage output side. While cheaper to make, it's a significant safety risk. If a fault occurs, that high voltage can pass directly to the light fixture, creating a risk of electric shock6.

An isolated driver, on the other hand, uses a transformer to physically separate the input and output circuits. This creates a safety barrier. It's the standard for quality lighting in most parts of the world, especially for products going into homes and offices. I always advise my partners, like Shaz in the UAE, to specify isolated drivers7 for their projects. The small extra cost is minimal compared to the safety and reliability it provides.

Next, you must ensure the driver is a constant-current type. LEDs work best when they receive a steady, unchanging flow of electrical current. A constant-current driver does exactly that. It adjusts the voltage automatically to maintain a fixed current, which leads to consistent brightness and protects the LED chips from burnout. Some very cheap lighting uses a much worse method, which brings us to the cheapest and most problematic circuit of all.

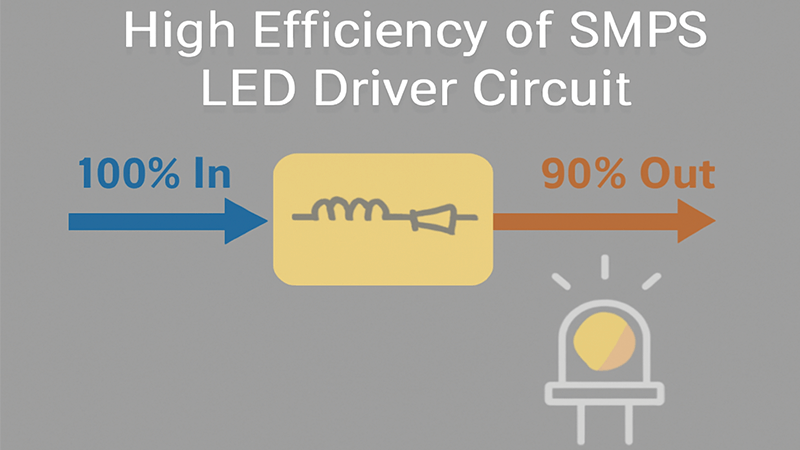

What is the most efficient LED driver circuit?

You want lights that save energy, but how do you know if the driver is truly efficient? A low-efficiency driver wastes electricity as heat, increases operating costs, and shortens the product's lifespan.

The most efficient and reliable LED driver circuits are Switched-Mode Power Supply (SMPS)8 designs, especially those using high-quality ICs from reputable brands9 like Texas Instruments, Power Integrations, or Infineon. These drivers offer high power factor10, minimal energy loss, and stable output for maximum LED longevity.

Let's break down the different levels of driver technology, from the worst to the best. This is the kind of insider knowledge that separates successful sourcing managers from those who are constantly dealing with product failures.

Level 1: Resistor-Capacitor (RC) Drivers

This is the absolute lowest-cost and lowest-quality method. It's not even a proper driver. It uses a simple capacitor to limit the current. I've torn down countless ultra-cheap downlights and found these inside. They are a disaster for performance. The output power fluctuates wildly with the input voltage, causing severe, often invisible, flicker. This flicker can cause headaches and eye strain. The power factor is extremely low, meaning it wastes a huge amount of energy as heat. This heat then cooks the LED chips, causing them to dim quickly and fail. If you see a downlight at an unbelievably low price, it likely uses an RC driver. Avoid it at all costs.

Level 2: Basic Non-Isolated Drivers using "Public Boards"

The next step up involves using a real driver Integrated Circuit (IC), but the execution is often poor. To save on R&D, many small factories buy pre-designed, generic driver circuit boards, often called "public boards." These boards are designed to be as cheap as possible, not for performance or reliability. They often use low-grade Chinese brand ICs and other cheap components. Because there's no custom design or optimization for the specific downlight, the performance is unstable. I've seen batches of lights using the same public board driver have failure rates skyrocket because of a tiny variation in the power grid.

Level 3: Quality Isolated Drivers with Brand-Name ICs

This is the gold standard. A quality driver is designed specifically for the lighting product it powers. Its core is a high-performance IC chip from a top-tier brand like Texas Instruments (TI), Power Integrations (PI), or Infineon. These chips are more expensive, but their performance and reliability are worlds apart from the cheap alternatives. These drivers are almost always isolated for safety and use better components throughout.

Here is a table to summarize the differences:

| Feature | Level 1: RC Driver | Level 2: Public Board Driver | Level 3: Quality Isolated Driver |

|---|---|---|---|

| Technology | Resistor-Capacitor | Non-Isolated or Isolated SMPS | Isolated SMPS |

| IC Quality | None | Low-grade domestic or Taiwanese | Top-tier brands (TI, PI, Infineon) |

| Performance | Severe flicker, unstable | Inconsistent, moderate flicker | Stable, no flicker |

| Efficiency (PF) | Very Low (<0.5) | Moderate (0.5 - 0.9) | High (>0.9) |

| Lifespan | Very Short (<5,000 hrs) | Short to Medium (15-25,000 hrs) | Long (50,000+ hrs) |

| Safety | Poor | Poor (if non-isolated) | Excellent |

| Cost | Extremely Low | Low | Moderate |

When you source lights, you can't see the IC brand, but you can demand a quality driver and ask the supplier for the technical data sheet. A good supplier will be proud to tell you they use top-tier components.

How to choose a driver for a LED light?

Knowing what makes a good driver is one thing. How do you apply that knowledge when sourcing? Choosing based on price alone is a trap that can lead to widespread product failures.

To choose the right driver, first specify an isolated, constant-current model. Then, ask the supplier for the driver's technical datasheet11 to verify its specifications, efficiency (Power Factor >0.9), and safety certifications. Finally, prioritize suppliers who use brand-name ICs.

As a purchasing manager, you have the power to demand quality. Too often, I see buyers focus only on the price of the downlight. But the real cost includes the risk of failure, replacement labor, and damage to your company’s reputation. A slightly higher initial investment in a quality driver pays for itself many times over. Here is the checklist I give my partners to ensure they source reliable products.

1. Demand an Isolated Driver

Make "isolated driver" a non-negotiable requirement in your product specifications. This is your first and most important filter for safety and quality. Any supplier who pushes back or says it's not necessary is prioritizing their profit margin over your product's safety and performance.

2. Check the Key Specifications

Once you have the driver's datasheet, check these numbers:

- Input Voltage: Make sure it matches the grid voltage of the destination country (e.g., 100-240V for wide compatibility).

- Output Current (mA): This must match the requirement of the LED chips in the downlight. The manufacturer should handle this, but it's good to know.

- Power Factor (PF): This measures efficiency. A good driver has a PF of 0.9 or higher. A low PF (like 0.5) means 50% of the energy is being wasted.

- THD (Total Harmonic Distortion): This is another sign of quality. Lower is better, and many regulations require it to be under 20%.

3. Ask About the IC Brand

Don't be shy. Ask the supplier, "What brand of IC do you use in your drivers?" A confident, quality-focused manufacturer will be happy to tell you they use brands like PI, TI, or Infineon. If they are evasive or say "a good Chinese brand," it is a major red flag. While the drivers may look identical from the outside, the performance gap between a top-tier IC and a generic one is enormous. I've seen it in my own testing labs. The reliability and stability are simply not comparable.

Choosing the right driver isn't about becoming an electrical engineer. It's about knowing the right questions to ask and the right standards to set. By focusing on these key points, you can cut through the noise and confidently select LED downlights that are built to last.

Conclusion

The best LED downlights use isolated, constant-current drivers with high-quality IC chips12. Prioritizing this technology ensures safety, eliminates flicker, maximizes efficiency13, and guarantees a long, reliable product lifespan.

Understand the potential risks associated with using cheap drivers in LED lighting. ↩

Explore the latest options for LED downlights to ensure you choose high-quality, reliable products for your projects. ↩

Discover the top LED chips that enhance the performance and longevity of downlights. ↩

Understand the causes of flicker in LED downlights and how to prevent it for a better lighting experience. ↩

Understand the differences between isolated and non-isolated drivers and their implications. ↩

Find safety tips to prevent electric shock when installing LED downlights. ↩

Learn about isolated drivers and their importance in ensuring safety and performance in LED lighting. ↩

Discover how SMPS technology improves the efficiency and reliability of LED drivers. ↩

Find out which brands are known for producing reliable LED driver ICs. ↩

Learn about power factor and its significance in the efficiency of LED drivers. ↩

Understand the key specifications found in a technical datasheet to make informed purchasing decisions. ↩

Find out which IC chips are considered high-quality and how they impact the performance of LED drivers. ↩

Learn how to assess the efficiency of LED drivers to ensure optimal performance. ↩