Struggling to choose the right optics for your downlights? A poor choice wastes energy and creates bad lighting. Mastering optical performance is key to achieving efficiency and quality.

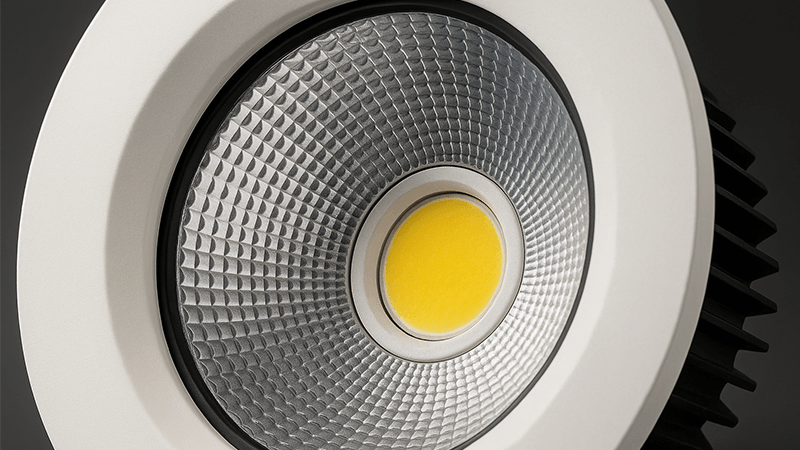

The best performance in COB LED downlights comes from high-transmittance reflectors1 or Total Internal Reflection (TIR) lenses2. Critically, the optical component's central axis must align with the COB chip3's center with less than a 0.5mm error to avoid a 15% or greater loss in efficiency.

Over my years in the lighting industry, I've seen countless projects compromised by a simple oversight: optical alignment4. Many focus on the LED chip or the driver, but the optic is what truly shapes the light. A tiny misalignment can turn a high-performance COB into an inefficient fixture. It's a detail I always stress to my partners because getting it right makes all the difference. Let's delve into why these details are so important and how you can ensure you're making the best choice every time.

Which is better SMD or COB LED lights?

Choosing between SMD and COB can be confusing. Making the wrong decision can impact your project's light quality and budget. Understanding their core differences is essential for success.

For focused lighting5 like downlights and spotlights, COB is generally better because it produces a single, uniform beam. For applications needing wide, dispersed light6 like bulbs or strip lights, SMD is superior.

I remember working with Shaz, a sharp purchasing manager from the UAE. For a new luxury hotel project, he needed focused, high-quality light in the hallways and over the reception desk. We went with COB downlights. The single, intense light source created beautiful, crisp light pools with no multi-shadow effect, which was perfect for the high-end feel he wanted. For the cove lighting and general back-of-house areas, he chose SMD strips for their broad, even coverage. He understood that it's not about one being "better" overall, but which is better for a specific job. To make the right choice like Shaz did, you need to break down their characteristics.

Light Quality and Appearance

COB (Chip on Board) technology mounts multiple LED chips directly onto a substrate to function as a single module. This creates one large light source. The result is a highly uniform beam of light that looks like it comes from a single point, similar to a traditional halogen bulb. This eliminates the multiple-shadow effect you can sometimes see with SMD arrays, making COB ideal for accent lighting and creating dramatic effects.

SMD (Surface Mounted Device) LEDs are individual chips soldered onto a printed circuit board (PCB). When you use them in a downlight, you're essentially using an array of small, distinct light points. While diffusers can blend this light, it inherently creates a wider, more dispersed output.

Heat Dissipation and Efficiency

Heat is the enemy of LEDs. COB has an advantage here. Because the LED chips are mounted directly to a thermally conductive substrate (often ceramic or aluminum), heat can be transferred away from the chips very efficiently. This direct thermal path7 allows COB LEDs to be driven harder and packed more densely without overheating, often leading to higher lumen output from a smaller area.

SMD LEDs have a more complex thermal path. Heat must travel from the chip, through its solder points, and into the PCB before it reaches a heat sink. While modern SMD designs are very effective, the direct path of COB is fundamentally more efficient at dissipating heat.

Application Suitability

The best choice ultimately depends on the final product.

| Feature | COB (Chip on Board) | SMD (Surface Mounted Device) |

|---|---|---|

| Light Source | Single, uniform point of light | Multiple, discrete points of light |

| Light Quality | No multiple shadows, intense, focused beam | Wider spread, can create multiple shadows |

| Heat Management | Superior, direct thermal path to substrate | Good, but a more complex thermal path |

| Best For | Downlights, track lights, spotlights | Bulbs, linear strips, panel lights |

| Typical Use Case | High-end retail, galleries, architectural lighting | General illumination, signage, backlighting |

For any high-performance downlight where quality of light and punch are key, COB is my go-to recommendation. For broader, more general lighting, SMD offers great flexibility and cost-effectiveness.

What is the maximum length of COB LED?

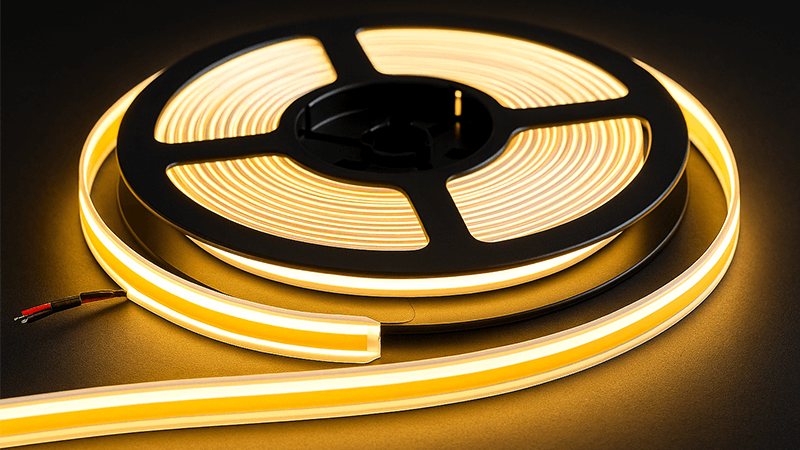

You're designing a space with long, seamless lines of light. You want to use COB strips for their dotless look, but you're worried about how far you can run them. This is a common and critical technical challenge.

The standard maximum length for a single run of a COB LED strip is typically 5 meters (16.4 feet). While longer physical strips can be made, performance drops significantly due to voltage drop over this length.

One of my clients was working on a large commercial office and wanted to use COB strips for continuous cove lighting around a massive open-plan space. The total length was over 30 meters. He initially planned to just connect multiple 5-meter strips end-to-end, powered from a single source. I had to step in and explain the problem of voltage drop8. If he had done that, the start of the strip would have been bright, but the end would have been noticeably dim and might have had a different color tint. It would have ruined the entire effect. We re-engineered the wiring plan to solve this, ensuring perfectly even light across the entire 30-meter run.

Understanding Voltage Drop

Voltage drop is a fundamental principle of electricity. As electricity flows along a wire (or in this case, the copper trace on a flexible PCB), it loses a small amount of voltage due to the resistance of the material. The longer the wire, the greater the voltage loss. For LED strips, this is a big deal. LEDs are designed to operate at a specific voltage (e.g., 24V). If the voltage drops to 22V by the end of the strip, the LEDs there will receive less power and produce less light. This causes the dimming effect you see on long runs.

Why 5 Meters is the Standard

Manufacturers standardized at 5 meters for a few key reasons:

- Manageable Voltage Drop: At 5 meters, the voltage drop on a well-made 24V strip is usually acceptable, with only a minor, often imperceptible, drop in brightness at the very end.

- Power Supply Practicality: Powering a 5-meter strip requires a reasonably sized power supply. Longer runs would require much larger, more expensive, and harder-to-hide drivers.

- Handling and Installation: A 5-meter reel is a convenient size for installers to handle and transport.

Solutions for Extending COB Runs

So how do you create runs longer than 5 meters? You should never just connect strips end-to-end in series. Instead, you use a parallel wiring method.

| Solution | How It Works | Best For |

|---|---|---|

| Power from Both Ends | Run a separate power wire from the power supply to the start and end of a strip up to 10 meters long. | Runs between 5 and 10 meters. Helps balance the voltage. |

| Power from the Middle | Run power to the center of a 10-meter run, effectively creating two 5-meter runs in opposite directions. | A single 10-meter installation where the power supply can be hidden in the middle. |

| Separate Parallel Runs | Run a new set of power wires from the power supply directly to each 5-meter segment. | The most professional and scalable method for very long runs (10m, 20m, 30m+). Ensures every strip gets the full voltage. |

By using these techniques, we were able to give my client the flawless, continuous light he envisioned for his office project. Understanding voltage drop isn't just technical—it's essential for achieving a professional result.

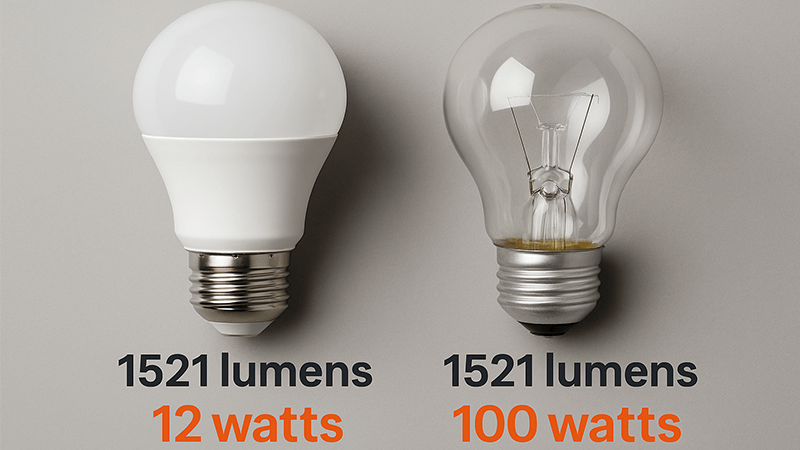

What is the LED equivalent to a 100 watt bulb?

You're trying to replace old 100-watt incandescent bulb9s. But the packaging on LED bulbs is confusing, with watts, lumens10, and "equivalents" all listed. You just want a simple answer.

To replace a 100-watt incandescent bulb, you need an LED bulb that produces around 1600 lumens. This typically corresponds to an LED bulb with an actual power consumption of about 15 to 18 watts.

In the early days of LED adoption, this was the biggest hurdle for my customers. I had a distributor, let's call him Shaz, who was trying to sell LED replacements to large facilities. His customers were used to buying bulbs based on watts. They'd ask for a "100-watt replacement" and he'd show them a 17-watt LED. They were skeptical that something using so little power could be as bright. I told him to stop talking about watts and start talking about lumens. Watts measure energy use, but lumens measure brightness. Once he started training his sales team to say, "This 17-watt LED gives you the same 1600 lumens of light as your old 100-watt bulb, but saves you 83% on energy," his sales took off.

Shift from Watts to Lumens

For a century, we bought light based on power consumption (watts). A 100W bulb was brighter than a 60W bulb. It was simple. This worked because all incandescent bulbs were similarly inefficient—they all converted about 90% of their energy into heat and 10% into light.

LED technology completely changed this relationship. LEDs are incredibly efficient at turning electricity into light. This efficiency is measured in lumens per watt (lm/W).

- Incandescent Bulb: ~16 lm/W (A 100W bulb produces 1600 lumens)

- LED Bulb: ~100 lm/W (A 16W LED bulb can also produce 1600 lumens)

Because LED efficiency is always improving, using watts to judge brightness is no longer reliable. A new 14W LED might be as bright as an older 18W LED. The only constant is the lumen output.

Understanding the "Equivalent" Rating

To help people transition, manufacturers started using "watt equivalent" ratings. An LED package might say "100-Watt Equivalent" or "Replaces 100W". This is a marketing tool to bridge the gap. However, the most accurate number to look for is always the lumen output, which is legally required to be on the "Lighting Facts" label in many countries.

Here's a simple conversion chart to help you shop:

| Old Incandescent Watts | Required Lumens (Approx.) | Typical LED Watts |

|---|---|---|

| 40W | 450 lm | 4-6W |

| 60W | 800 lm | 8-10W |

| 75W | 1100 lm | 11-13W |

| 100W | 1600 lm | 15-18W |

| 150W | 2600 lm | 25-28W |

So when you're looking to replace a 100-watt incandescent bulb, ignore the LED's wattage. Find the lumens number on the box and look for something around 1600 lm. This is the only way to guarantee you'll get the brightness you expect.

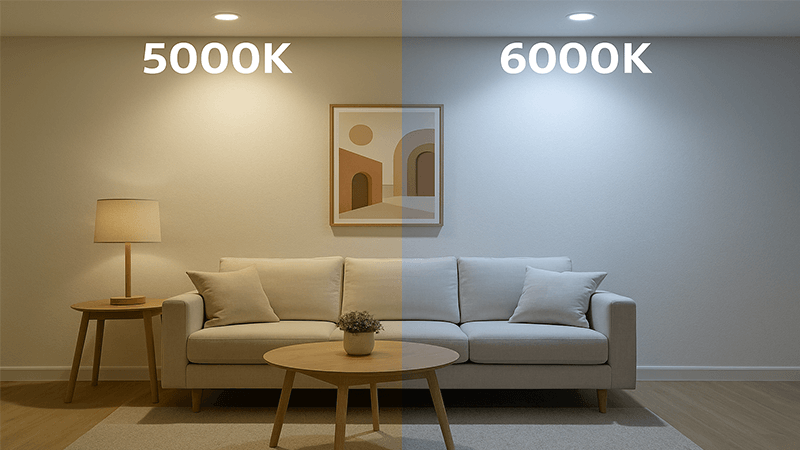

Is 5000K or 6000K brighter?

You're choosing between 5000K and 6000K lights for a project. You want the brightest possible option, but you're not sure if the color temperature11 number relates directly to brightness.

Technically, 5000K and 6000K lights with the same lumen rating have the same brightness. However, the human eye often perceives the cooler, bluer light of 6000K as being slightly "brighter" or more intense than the neutral white of 5000K.

This is a subtle but important point that I often discuss with project managers. I was helping a client choose lighting for a large warehouse in the UAE. He just wanted "the brightest light for safety and productivity." We set up a test area with two high-bay fixtures. Both had the exact same 20,000-lumen output. One was 5000K, and the other was 6000K. When he and his team walked in, nearly everyone pointed to the 6000K fixture and said it felt brighter and crisper. Even though the light meter told us they were identical in brightness (lumens), the perceived difference was undeniable. They chose the 6000K. This perception is key when choosing between these two color temperatures.

The Difference Between Lumens and Kelvin

It's crucial to separate two different concepts:

- Lumens (lm): This is the scientific measurement of luminous flux, or the total amount of visible light produced by a source. It is a direct measure of brightness. A 2000 lumen bulb is brighter than a 1500 lumen bulb, period.

- Kelvin (K)12: This is the measurement of Correlated Color Temperature (CCT). It describes the color appearance of the light, from warm (low K) to cool (high K). It has no direct relationship with the amount of light.

Think of it like painting a room. Lumens are how much paint you have in the can. Kelvin is the color of that paint (e.g., beige vs. stark white).

5000K vs. 6000K: Perception and Application

While the brightness is the same at an identical lumen rating, the feel and psychological impact of these two color temperatures are quite different.

| Color Temp | Color Description | Psychological Effect | Best Applications |

|---|---|---|---|

| 5000K | Neutral / Pure White | Clean, balanced, clear. Mimics midday sun. | Offices, retail, workshops, garages, hospitals. Good for task visibility without being harsh. |

| 6000K | Cool White / Bluish White | Crisp, intense, sterile. Mimics daylight on a clear day. | Warehouses, manufacturing plants, outdoor security lighting, display cases for diamonds. Excellent for high-alertness areas. |

The slightly bluer content in 6000K light can stimulate photoreceptors in our eyes that are linked to alertness. This is why it can feel "brighter" and more intense and is often favored in industrial or security settings where maximum perceived visibility is the goal. However, that same blueish tint can feel sterile or harsh in an office or retail environment, where the more balanced, neutral look of 5000K is often preferred.

So when choosing, ask yourself what the goal is. If you need measured, certified brightness, trust the lumen rating. If you're looking for a light that feels the most intense and promotes alertness, 6000K might be the better choice, even at the same lumen level as a 5000K option.

Conclusion

Choosing the right COB optics, understanding LED specs like lumens and Kelvin, and knowing the difference between COB and SMD are all critical for achieving exceptional lighting and efficiency.

Explore how high-transmittance reflectors enhance LED performance and efficiency. ↩

Learn about TIR lenses and their role in maximizing light output in LED fixtures. ↩

Understand the technology behind COB chips and their advantages in lighting applications. ↩

Discover the significance of optical alignment for achieving optimal lighting performance. ↩

Explore the concept of focused lighting and its applications in various settings. ↩

Learn about dispersed light and its benefits for general illumination. ↩

Discover how the thermal path impacts LED performance and heat management. ↩

Understand voltage drop and its effects on LED strip performance and brightness. ↩

Discover the LED equivalent to a 100-watt incandescent bulb for energy-efficient lighting. ↩

Explore the concept of lumens and how they relate to brightness in LED bulbs. ↩

Understand color temperature and its impact on the appearance of light in different settings. ↩

Learn about Kelvin as a measurement of color temperature in lighting applications. ↩