Tired of downlights that flicker, change color, and fail prematurely? These issues cost you time, money, and damage your reputation with clients. The solution isn't finding a fancy brand name, but understanding the real source of quality.

The 'best' downlight manufacturer isn’t a famous brand. It’s the one with strict, end-to-end control over its entire supply chain. From the specific bin of LED chip to the last capacitor in the driver, consistent quality comes from deep process discipline, not just assembly.

For over a decade, I've lived and breathed LED lighting. I started on the factory floor and eventually built my own manufacturing business, iPHD. In that time, I’ve seen it all. I've seen big brands fail and small, disciplined factories produce incredible products. My friend Shaz, a top purchasing manager in the UAE, often asks me the same questions you're probably thinking about. He needs to know what truly separates a reliable product from a liability. Forget the marketing hype. Let's dissect these questions to reveal the engineering and sourcing truths that will empower you to choose with confidence.

Who makes the best quality LED lights?

Are you frustrated by getting a great batch of LEDs one month, and a terrible one the next? This inconsistency ruins projects and erodes trust. The secret to consistent quality isn't luck; it's a fanatical devotion to supply chain control.

The highest quality LED lights come from true manufacturers, not assemblers. A top-tier maker controls every critical component: they specify the exact LED chip bin for color consistency, use drivers with high-temperature capacitors, and verify performance with their own testing data (like LM-80 reports).

The term 'manufacturer' is thrown around too easily. Most are just assemblers. They buy components on the open market based on price that week. One month they use a quality driver; the next, a cheaper one to save a dollar. This is why you see so much variation. A true manufacturer has a fixed Bill of Materials (BOM)1 rooted in engineering, not daily market prices. Let’s talk specifics. For color consistency, we specify LED chips from a very tight "bin," ensuring every light in an order looks identical—this is known as a 3-step MacAdam ellipse2 or less. For the driver, the electronic heart of the fixture, we specify components like high-temperature capacitors3 (rated for 105°C, not 85°C) because heat is what makes drivers fail. I’ve seen cheap drivers where the capacitors bulge and leak after just a year. We demand and verify third-party and in-house test reports, like LM-80 data, which prove how the light output will be maintained over thousands of hours. An assembler won’t have this data because they don't even know what chips they'll use next month. This discipline is the difference.

| Key Aspect | Standard Assembler | Disciplined Manufacturer (iPHD) |

|---|---|---|

| LED Chip Sourcing | Open market, whatever is cheapest. | Specified brand and tight bin (e.g., 3-step MacAdam ellipse). |

| Driver Components | Low-cost capacitors, basic ICs. | High-temperature capacitors (105°C), stable ICs. |

| Quality Data | None provided, or uses generic supplier data. | Provides specific LM-80 and TM-21 reports for their product. |

| Result | Inconsistent color, high failure rates. | Perfect color consistency, proven reliability. |

Are expensive downlights worth it?

Do you look at two downlights that seem identical, yet one costs three times more? It’s tempting to choose the cheaper one, but that choice can lead to massive long-term costs. The higher price is not for the light; it's for what protects the light.

Yes, expensive downlights are worth it because you are buying insurance against "thermal debt." You pay for superior thermal management—a heavy, well-designed heat sink—that protects the LED chip from overheating. This ensures the fixture lasts its stated life and maintains its light quality.

Every LED generates heat at its core, the junction. We call this the junction temperature (Tj). The single most important factor in an LED’s life is keeping this temperature low. A cheap downlight is an expert at hiding its fatal flaw. It might use an underpowered LED chip and "overdrive" it—pushing more electricity through it than it's designed for—to hit a high lumen number on the box. This sends the Tj soaring. The heat has nowhere to go because the heat sink is just a thin piece of stamped aluminum, or worse, plastic. This creates "thermal debt4." The light works at first, but the debt comes due as the heat slowly cooks the LED chip and its phosphor coating. The light output fades fast (poor lumen maintenance5), the color shifts (often turning blue or green), and the fixture fails years before its promised 50,000 hours. A quality downlight invests in thermal engineering. It uses a heavy, die-cast aluminum heat sink with a large surface area and fins to effectively pull heat away from the chip. You are paying for a sophisticated thermal path that guarantees the fixture's long-term performance.

| Component | Inexpensive Downlight | Quality Downlight |

|---|---|---|

| Design Philosophy | Hits a lumen target at the lowest cost. | Manages heat for maximum lifespan (L70). |

| Heat Sink | Thin, light aluminum or plastic. Poor thermal path. | Heavy, die-cast aluminum with engineered fins. |

| LED Driving | Often overdriven to appear brighter initially. | Driven at optimal current for efficiency and low heat. |

| Long-Term Cost | High thermal debt leads to early failure, replacement costs. | No thermal debt. Pays for itself in reliability and longevity. |

How many lumens should a downlight be?

Are you basing your purchasing decisions on who has the highest lumen number? This is a trap that leads to uncomfortable, poorly lit spaces filled with glare. The goal is not "more light," but "better light."

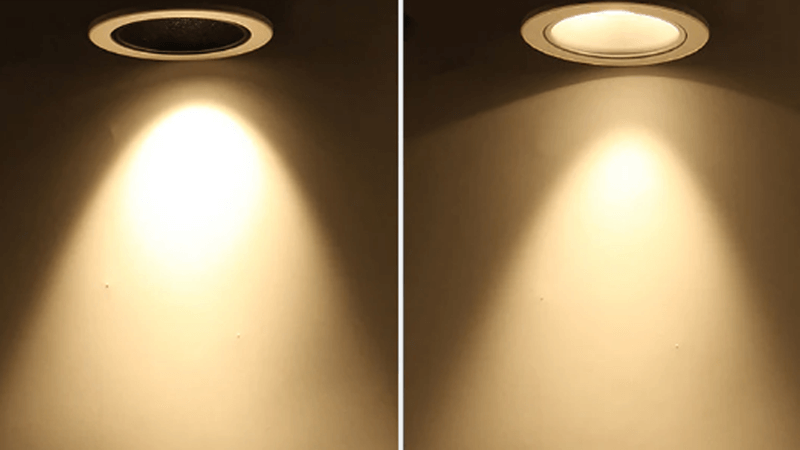

The ideal lumen count depends on the application, but focusing on raw lumens is a mistake. Prioritize 'useful lumens6' delivered with excellent glare control7 (a UGR < 19 is good). For most ambient lighting8, 600-800 well-controlled lumens are far superior to 1200 lumens sprayed everywhere.

"Junk lumens" are what I call the output from a poorly designed fixture. They contribute to the number on the spec sheet but also create disabling glare, making a room feel unpleasant. This happens when the light source itself is visible. Good lighting design is about seeing the effect of the light, not the source. A quality downlight achieves this with superior optics. It will have a deep-set LED, hiding the chip from the direct line of sight. It will then use a precisely engineered Total Internal Reflection (TIR) lens9 or a high-purity aluminum reflector to control the beam, shaping the light and directing it only where it's needed. This delivers high "useful lumens" with a low Unified Glare Rating (UGR). Furthermore, "useful" also means high-quality light. What good are high lumens if the colors in the room look flat and washed out? That’s where the Color Rendering Index (CRI)10 comes in. A CRI of 90+ ensures colors look vibrant and natural. For projects where reds are important, like restaurants or retail, we even specify a high R9 value11. A cheap, high-lumen downlight almost always has a low CRI of around 80.

| Space Application | Recommended "Useful" Lumens | Key Quality Metrics |

|---|---|---|

| Residential Living | 600-800 lm | Warm CCT (2700-3000K), CRI 90+, UGR < 19 |

| Kitchen Task Areas | 800-1000 lm | Neutral CCT (4000K), CRI 90+, Focused Beam |

| Office/Commercial | 800-1200 lm | Neutral CCT (4000K), CRI 90+, UGR < 19 (Critical) |

| Accent/Art Lighting | 400-800 lm | High CRI (>95), High R9, Narrow Beam (10-25°) |

Which is better, downlight or spotlight?

Are you stocking dozens of different SKUs for fixed downlights, adjustable downlights, and spotlights? This complicates your inventory, increases costs, and limits design flexibility12. This entire way of thinking is obsolete.

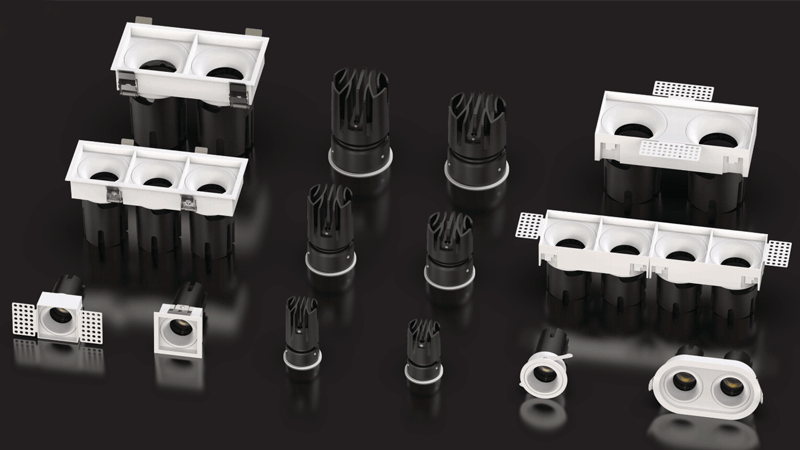

Neither is better because the modern fixture is a flexible 'recessed aperture platform.' This approach uses one universal housing that accepts different field-interchangeable light modules. You can create a wide-beam downlight or a narrow-beam, tiltable spotlight from the same installed fixture.

Let me explain why this platform approach is a revolution for a purchasing manager like Shaz. In the old model, he would have to forecast and order separate fixed 40° downlights, adjustable 25° spotlights, and maybe even wall-washers. Each was a completely different product. This meant more inventory, more capital tied up, and the risk of being stuck with the wrong product if a project's needs changed. The platform changes everything. Today, electricians install one common type of recessed housing throughout a project. Later, even after the ceiling is painted, you simply click in the desired light module. The client wants general ambient light in the corridor? Click in the 60° downlight module. They decide to hang a painting on a wall? Swap it for a 15° adjustable spotlight module. This provides incredible on-site flexibility. For you as the buyer, it is a massive simplification. You stock one or two housing types and a range of much smaller, cheaper light modules. This reduces your inventory value, lowers risk, and allows you to offer your clients a level of customization that was previously impossible without huge costs and delays. It is the future of intelligent lighting specification.

| Aspect | Old Method (Separate Fixtures) | New Method (Platform Approach) |

|---|---|---|

| Inventory | High. Many distinct, bulky SKUs. | Low. One housing SKU, multiple small module SKUs. |

| Logistics | Complex forecasting, higher shipping volume. | Simplified forecasting, reduced shipping volume. |

| Project Flexibility | Zero. Function is fixed upon installation. | Maximum. Change light effect anytime by swapping modules. |

| Future-Proofing | None. A redesign requires a new fixture. | Complete. Upgrade or change function without touching ceiling. |

Conclusion

The best downlight isn't about a brand. It’s defined by supply chain control, smart thermal design, a focus on useful, high-quality light, and a flexible platform approach.

Learn how a fixed BOM ensures quality and consistency in LED lighting products. ↩

Discover how this specification ensures color consistency in LED products. ↩

Explore the role of high-temperature capacitors in enhancing LED reliability. ↩

Discover how thermal debt affects the lifespan and performance of LED fixtures. ↩

Learn how lumen maintenance affects the long-term performance of LED lights. ↩

Understanding useful lumens can help you achieve better lighting quality in your spaces. ↩

Learn how effective glare control can improve comfort and visibility in spaces. ↩

Discover the importance of ambient lighting in creating inviting spaces. ↩

Explore how TIR lenses improve light distribution and reduce glare. ↩

Learn how CRI affects the appearance of colors in your lighting design. ↩

Find out how a high R9 value enhances color accuracy in lighting applications. ↩

Discover how flexible designs can adapt to changing project needs and preferences. ↩