Are your hallway lights failing too often? Dust and moisture can cause premature failure. Architects recommend IP44 downlights1 for their superior durability and long-term reliability in these high-traffic areas2.

Architects recommend IP44 downlights for hallways because they protect against dust and moisture. This ensures a longer lifespan, consistent performance, and enhanced safety in corridors, which often experience temperature changes that can cause condensation3. These lights simply last longer and perform better.

I've worked in the lighting industry for my entire career, starting on the factory floor. I’ve seen firsthand how a small detail, like an IP rating4, can make or break a project's long-term success. Hallways and corridors are more than just passages; they set the first impression of a space. Architects understand that these areas face unique environmental challenges, even if they aren't obviously "wet" like a bathroom. They need lighting that will not fail. Let's dig into why IP44 is their go-to choice and what it means for your projects.

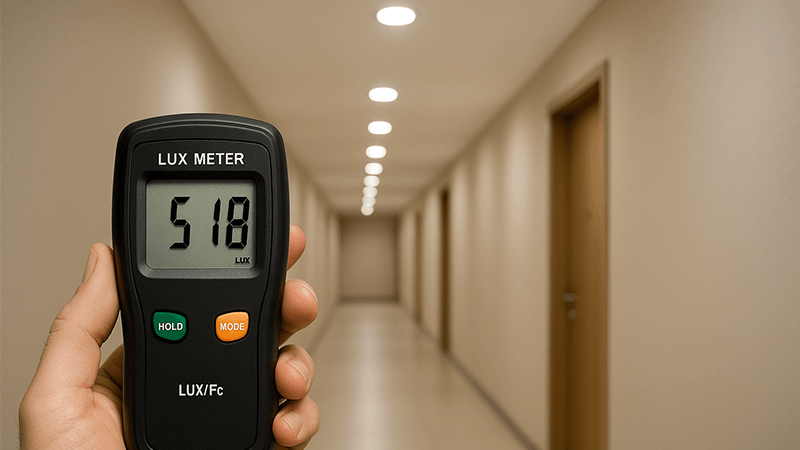

What is the minimum lighting level for corridors and hallways?

Is your hallway too dark? This creates safety risks and feels unwelcoming. Adhering to minimum lighting standards ensures a safe and comfortable passage, preventing trips and falls effectively.

The minimum recommended lighting level for residential hallways is around 50 to 100 lux5. For commercial spaces like offices or hotels, this increases to 100 to 150 lux to ensure safety, clear visibility, and easy navigation for higher foot traffic.

Dive Deeper

Getting the lighting level right is one of the most basic but crucial parts of a lighting plan6. The unit we use to measure the amount of light falling on a surface is called "lux". One lux is equal to one lumen per square meter. It is a measure of light intensity as our eyes perceive it.

Understanding Lux and Its Importance

Different tasks and environments need different lux levels7. A workshop where detailed work is done might need 500 lux or more. An office requires around 300-500 lux for comfortable reading and computer work. Hallways, however, are primarily for transit. The goal is to provide enough light for safe navigation without making the space uncomfortably bright or wasting energy. A low lux level can make a space feel gloomy and can be a safety hazard, especially for older people or in public buildings.

Recommended Lux Levels for Different Corridors

The right level depends entirely on the building's use. I remember working on a project for a luxury hotel in the UAE. The client, a purchasing manager named Shaz, had a specification from the architect for 150 lux in all corridors. This was higher than for a typical residential building but essential for creating a bright, secure, and high-end feel for guests.

Here is a simple table to guide you:

| Corridor Type | Minimum Recommended Lux Level | Rationale |

|---|---|---|

| Residential Home | 50 - 100 lux | Ensures safe passage, comfortable ambiance. |

| Office Building | 100 - 150 lux | Accommodates higher traffic, enhances safety. |

| Hotel | 100 - 150 lux | Creates a welcoming, secure atmosphere for guests. |

| Hospital / Healthcare | 150 - 200 lux | Critical for patient and staff safety, clear visibility. |

Beyond just the lux level, we also focused on uniformity8. It’s not enough to hit an average of 150 lux if there are dark spots between lights. Proper spacing, which we will discuss later, is key to achieving a smooth, even light that looks professional and is safe.

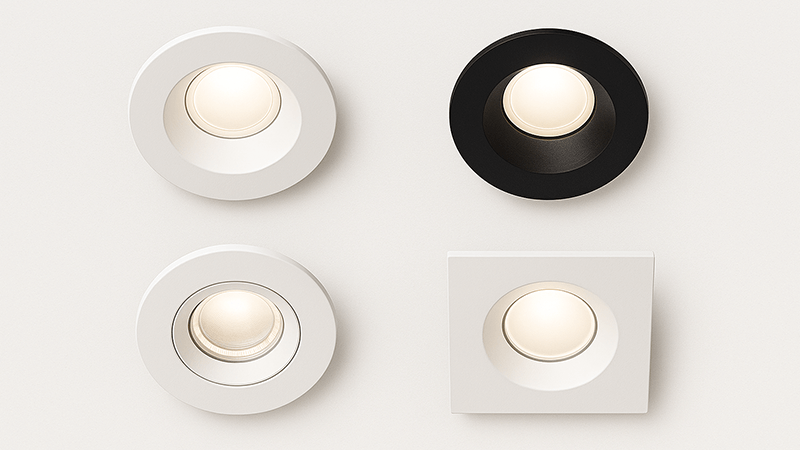

What is an IP44 downlight?

Confused by lighting jargon like IP44? Choosing the wrong product can lead to failure and project delays. Understanding this simple rating helps you select durable, appropriate lighting every time.

An IP44 downlight is a light fixture protected against solid objects larger than 1mm (the first '4') and water splashes from any direction (the second '4'). This makes it resistant to dust and moisture, ideal for hallways, kitchens, and certain bathroom zones.

Dive Deeper

The IP rating, which stands for Ingress Protection, is a standard used to define the levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies and moisture. As a manufacturer, this is one of the most important specifications we build for.

Breaking Down the 'IP' Code

The code is always followed by two numbers.

- First Digit (Solids): This number ranges from 0 to 6 and shows the level of protection against solid objects, from hands to microscopic dust.

- Second Digit (Liquids): This number ranges from 0 to 8 and shows the level of protection against moisture, from drips to full submersion.

For an IP44 rating:

- The first '4' means it is protected against solid objects greater than 1mm. This is important for keeping out insects and large dust particles.

- The second '4' means it is protected against water splashes from any direction. It won’t survive a jet spray, but it can handle condensation and splashes.

The Unseen Details of a True IP44 Downlight

Achieving a true, reliable IP44 rating involves more than just a gasket. From my experience on the factory floor, here are some insider details.

-

Sealed for Life: Many customers are surprised that most IP44 downlights are fully sealed units where you cannot replace the bulb. This isn't a flaw; it's a critical design feature. It guarantees the IP rating is maintained for the life of the product. An end-user changing a bulb could easily compromise the seal. We design them for a lifespan of 30,000-50,000 hours, so replacement is infrequent.

-

The Driver is the Weak Link: I can say with confidence that about 80% of LED downlight failures9 are caused by the driver, not the LED chip. For an IP44 fixture, the driver must also be protected from moisture. The best way to do this is with a process called glue-potting, where the driver's internal components are fully encased in a waterproof resin. This adds cost but is the only way to ensure the downlight lasts in a humid environment. Many cheap "IP44" lights use a standard driver, and they will fail.

-

A Superior Lens: Moisture and humidity can cause the lens of a standard downlight to turn yellow and brittle over time, reducing light output. A quality IP44 downlight uses a lens made from materials with higher anti-corrosion and UV-resistant properties to ensure optical clarity and efficiency for years.

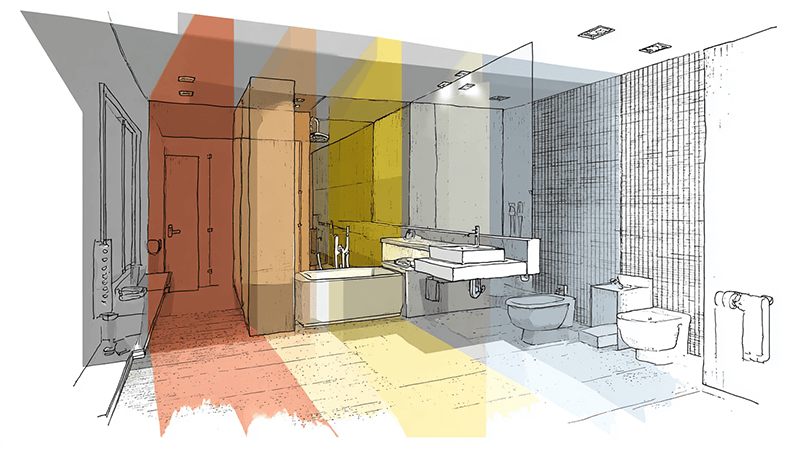

Do all bathroom lights need to be IP44?

Confused about bathroom lighting safety10? The wrong fixture in a wet zone is a serious hazard. Learning bathroom zones helps you choose compliant, safe lighting fixtures without any guesswork.

No, not all bathroom lights need to be IP44. The required IP rating depends on the "zone." Areas directly exposed to water, like inside a shower (Zone 1), need IP65. IP44 is suitable for areas around the sink or bath (Zone 2).

Dive Deeper

Bathroom electrical safety is rightly governed by strict regulations. Water and electricity are a dangerous mix. To simplify safety rules, bathrooms are divided into different zones based on their proximity to a water source. Each zone has a minimum required IP rating.

Understanding Bathroom Electrical Zones

Think of these zones as circles of risk radiating out from the taps.

-

Zone 0: This is inside the bath or the shower tray itself. Any fitting used here must be low voltage (max 12V) and be rated at least IP67, which is total immersion proof.

-

Zone 1: This is the area directly above the bath or shower, up to a height of 2.25m from the floor. Fixtures here need a rating of at least IP65, which protects against jets of water.

-

Zone 2: This is the area stretching 0.6m outside the perimeter of the bath and shower, and the area around the sink, also to a height of 2.25m. The minimum required rating here is IP44, which protects against splashes.

-

Outside Zones: This refers to any area outside of zones 0, 1, and 2. There is no specific IP rating required here by law, but we always recommend using at least IP20 to protect against finger-sized objects.

Why Corridors Can Be Like a Bathroom's Zone 2

So, why does this matter for hallways? A hallway isn't a bathroom. But in certain conditions, it can behave like one. I once consulted on a project for a large apartment complex. The corridors had no active ventilation. In the winter, warm air from the apartments would hit the cold corridor walls, causing condensation to form. The standard IP20 downlights they installed started failing within 18 months due to moisture getting into the electronics.

This is why a smart architect often specifies IP44 for corridors, especially in hotels, multi-family housing, or coastal areas. They are planning for unseen environmental factors. They are treating the hallway like a bathroom's Zone 2: an area where direct water exposure is unlikely, but ambient moisture11 and condensation are a real risk. It’s a decision that prevents premature failure and protects the investment.

How many downlights do I need in the hallway?

Struggle with downlight spacing12 in hallways? Too few create shadows, while too many cause glare and waste energy. A simple rule helps you calculate the ideal number for even, efficient lighting.

As a general rule, place downlights about 1 to 1.5 meters apart in a hallway. Also, keep the first and last lights about 0.5 to 1 meter from the end walls to avoid casting harsh shadows. The exact number depends on ceiling height and light output.

Dive Deeper

Calculating the exact number of downlights can seem complex, but for a linear space like a hallway, focusing on spacing rules is more practical than relying on pure lumen calculations. The goal is to create a 'scallop' of light on the walls that overlaps nicely, providing a smooth, uniform glow without dark patches.

The Golden Rule of Downlight Spacing

For most hallways with a standard ceiling height (2.4m to 2.7m), follow these two simple rules:

-

Space Lights 1m to 1.5m Apart: This is the distance between the center of each downlight. Spacing them closer than 1m is often too bright and wasteful. Spacing them further than 1.5m can create dark spots and an uneven look.

-

Position End Lights 0.5m to 1m from the Wall: Never place the first or last downlight right up against the start or end wall. This creates an ugly, harsh shadow. Pulling it back by half the spacing distance (e.g., if spacing is 1.5m, place the first light 0.75m from the wall) creates a much softer and more pleasing effect.

The Impact of Beam Angle

The beam angle13 of the downlight plays a big role in spacing. A wider beam angle spreads light over a larger area, which means you might be able to space the lights further apart.

| Beam Angle | Use Case | Recommended Spacing (for 2.7m ceiling) |

|---|---|---|

| Narrow (15°-25°) | Accent lighting, highlighting artwork | Not for general hallway use |

| Medium (36°-45°) | Good all-purpose, balances focus and spread | 1.2m - 1.5m |

| Wide (60°+) | General ambient light, maximum coverage | 1.5m - 1.8m |

For most hallways, a medium beam angle of around 40° is a perfect choice. It gives great coverage without feeling flat.

A Practical Example

Let's apply this to a 9-meter long hotel corridor.

- We choose a 40° beam angle IP44 downlight.

- We will use a spacing of 1.5 meters between lights.

- We place the first light 0.75m from the starting wall.

- We then place the following lights at: 2.25m, 3.75m, 5.25m, 6.75m, and 8.25m.

- This gives us a total of 6 downlights. The last light is 0.75m from the end wall, perfectly matching the start. The result is beautiful, uniform light that guides people safely and comfortably down the corridor.

Conclusion

Architects choose IP44 downlights for hallways for durability against moisture and dust. Understanding IP ratings, lux levels, and proper spacing ensures a safe, reliable, and perfectly lit corridor.

Explore the advantages of IP44 downlights for durability and safety in high-traffic areas. ↩

Discover effective lighting solutions designed for durability in high-traffic environments. ↩

Learn about the risks of condensation and how to choose fixtures that withstand moisture. ↩

Learn how IP ratings help in selecting the right lighting fixtures for different environments. ↩

Understand the significance of lux in creating effective lighting plans for various environments. ↩

Discover tips for designing a lighting plan that enhances safety and ambiance in hallways. ↩

Get insights into appropriate lux levels for various corridor types to ensure safety. ↩

Find out how uniform lighting improves safety and aesthetics in corridor spaces. ↩

Find out the common causes of downlight failures and how to choose reliable fixtures. ↩

Understand the safety standards necessary for effective lighting in public areas. ↩

Explore the effects of ambient moisture on lighting fixtures and how to mitigate risks. ↩

Explore guidelines for spacing downlights to achieve optimal lighting without glare. ↩

Understand how beam angle affects light distribution and spacing in hallway lighting. ↩