Are you frustrated by lighting designs ruined by hotspots and uneven shadows? This inconsistency cheapens a project, but COB LED downlights1, engineered correctly, are the professional's solution for smooth, even light.

COB LED downlights achieve superior uniformity through a single, dense array of chips paired with advanced optics like reflectors and lenses. This design transforms the intense point source into a smooth, perfectly blended beam without multi-shadow effects.

When I first started in this industry, I saw many projects struggle with lighting quality2. A common issue was unevenness, which made expensive spaces look cheap. Many people think COB technology3 itself is the magic bullet for uniformity. However, the raw COB chip is actually a very intense, single point of light. Left alone, it can create harsh spots and yellow rings. The real secret isn't just the chip; it's how we build the entire downlight fixture4 around it. The engineering of the reflector and lens is what takes that powerful point source and shapes it into the beautifully uniform light your projects demand. Let's explore how this works.

What is uniformity in lighting design?

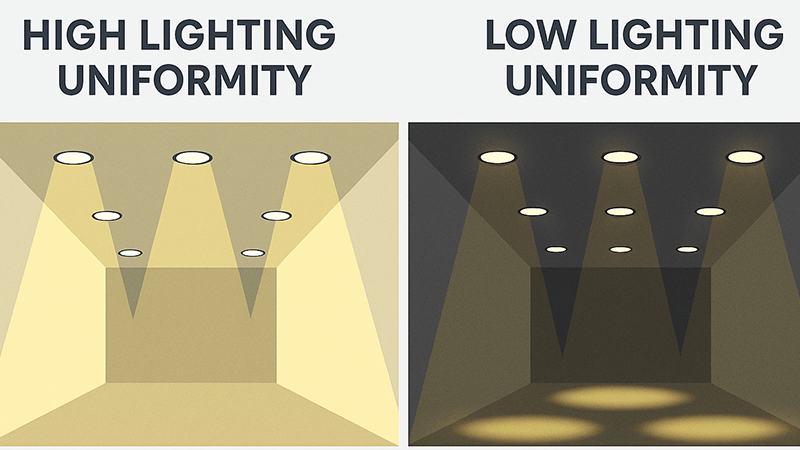

Have you heard engineers talk about "uniformity" but weren't sure what it meant for your projects? This uncertainty can lead to specifying the wrong products and getting poor results.

Uniformity in lighting is the measure of how evenly light is spread across a specific area. It is calculated as a ratio, where a higher value indicates fewer distracting bright and dark spots.

Think of lighting uniformity5 like watering a garden. You want to give every plant the same amount of water, not flood one area while another stays dry. In lighting, we measure the amount of light hitting a surface in "lux." Uniformity is simply a number that tells us how consistent that lux level is across the whole surface.

We calculate it with a simple formula: Uo = Emin / Eavg.

- Emin is the lowest light level (the darkest spot) on the surface.

- Eavg is the average light level across the entire surface.

A perfect uniformity score would be 1, but that's not realistic. The goal is to get as close as the application requires. For example, a general office space needs good uniformity to prevent eye strain, while a museum might intentionally use low uniformity to create dramatic accents.

As a purchasing manager, understanding this helps you communicate exact requirements to suppliers. It is the difference between asking for "good light" and specifying a "Uo of 0.7 for office workstations." This ensures you get the performance you pay for. Here’s a table to show why it matters:

| Application | Recommended Uniformity (Uo) | Why it Matters |

|---|---|---|

| Office/Task Areas | > 0.6 | Prevents eye strain, headaches, and fatigue. Ensures clear visibility for all tasks. |

| Retail (General) | > 0.5 | Creates a welcoming and open atmosphere. Ensures products are seen consistently. |

| Warehouse/Industrial | > 0.5 | Crucial for safety. Prevents accidents by eliminating dark corners and trip hazards. |

| Hallways/Circulation | > 0.4 | Provides safe navigation and a sense of security. Less critical than task areas. |

By specifying the right uniformity, you ensure the lighting not only looks good but also serves its functional purpose, improving safety and productivity.

What are the best uses for COB lights?

Choosing the wrong type of LED for the job can lead to wasted money and poor lighting. Using a COB light where it isn't needed is just as bad as not using one where it is.

COB lights are best used in applications that require a powerful, high-quality beam from a single source. This makes them perfect for high-ceiling downlights, track lights, and retail accent lighting.

The main strength of COB technology%%%FOOTNOTE_REF3%%% is its ability to pack a lot of lighting power into a very small area. This high "[lumen density](https://en.wikipedia.org/wiki/Lumen(unit))6" creates a strong, punchy light that works where other LEDs might fall short. When I work with project contractors, we always identify where the client needs focus and intensity. That's where COB lights truly prove their value. They are the tool we use for creating drama, highlighting features, and delivering powerful light over a distance.

Here are the primary applications where COB technology is the clear winner:

1. High-Ceiling Applications

In spaces like atriums, event halls, or warehouses with ceilings over 4 meters, you need light that can travel a long distance without losing its intensity. A COB downlight, paired with the right reflector, can project a strong, controlled beam to the floor, providing excellent illumination without needing an excessive number of fixtures.

2. Retail and Accent Lighting

This is where COB lights are superstars. In a retail store, you want to draw a customer's eye to specific products. A COB track light or spotlight creates a high-contrast, focused beam that makes merchandise look vibrant and appealing. The single-source nature of COB prevents the "multi-shadow" effect that can happen with SMD LED7s, giving products a cleaner, more premium look.

3. Architectural Spotlighting

When you need to highlight an architectural feature, like a textured wall or a column, a narrow-beam COB spotlight is the ideal tool. It can create sharp, defined pools of light, adding depth and visual interest to a space.

For a purchasing manager like Shaz, knowing these ideal use cases is critical. It allows you to guide your own team and question your suppliers to ensure you are sourcing the most effective and efficient solution for each part of a project, rather than taking a one-size-fits-all approach. For general, wide-area illumination in standard-height ceilings, a good SMD downlight can often be more cost-effective. But for punch, focus, and quality of light, COB is the professional choice.

What are the 4 types of lighting?

Are you creating lighting plan8s that feel flat or uninspired? Just filling a room with light isn't enough; this approach often ignores the way people actually use the space and a project's goals.

The four fundamental types of lighting in design are Ambient, Task, Accent, and Decorative. A great lighting plan skillfully layers these four types to create a space that is both functional and beautiful.

Early in my career, I visited a client's newly opened restaurant. They had installed a single grid of bright downlights. The space was well-lit but felt sterile, like an office. They had only used one type of lighting—ambient—and it failed to create any atmosphere. This experience taught me that how you layer light is as important as the fixtures themselves. A successful lighting scheme needs to be built with purpose, using each of the four types to fulfill a specific role.

Thinking about lighting in these four layers will transform how you approach your projects.

The Four Layers Explained

-

Ambient Lighting

- Purpose: This is the base layer, the general illumination that makes a space safe and navigable. It’s the "fill" light that provides overall brightness.

- Fixtures: Ceiling-mounted downlights (like COB or SMD), large pendants, or cove lighting.

- Effect: Creates a comfortable level of brightness without focusing on anything in particular.

-

Task Lighting

- Purpose: This is focused light for specific activities like reading, cooking, or working at a desk. It's all about function and preventing eye strain.

- Fixtures: Under-cabinet lights in a kitchen, a desk lamp in an office, or a reading light by a chair.

- Effect: Provides localized, brighter light right where it's needed for a task.

-

Accent Lighting

- Purpose: This is the "drama" layer. It's used to highlight focal points like artwork, architectural details, or retail products. COB spotlights and track lights excel here.

- Fixtures: Track lights, wall-mounted spotlights, or narrow-beam downlights.

- Effect: Creates visual interest and contrast, guiding the eye and adding depth to a room. It should be at least three times brighter than the ambient light to be effective.

-

Decorative Lighting

- Purpose: This layer is about aesthetics. The main purpose of the fixture is to be looked at, not necessarily to provide significant light. It's the "jewelry" of the space.

- Fixtures: Chandeliers, wall sconces, or unique pendant lights.

- Effect: Adds beauty, style, and character to the environment. The light it produces is secondary to its form.

For anyone managing procurement, understanding this framework allows you to source a complete lighting package. Instead of just buying 100 downlights, you can now structure your sourcing around the specific needs of the design: ambient downlights, task strips, accent spotlights, and a decorative centerpiece. This layered approach is the secret to world-class lighting design.

Which is better SMD or COB LED display?

Are you confused about whether to specify SMD or COB for your project? Choosing the wrong technology can impact cost, performance, and visual quality, making it a critical decision for any purchaser.

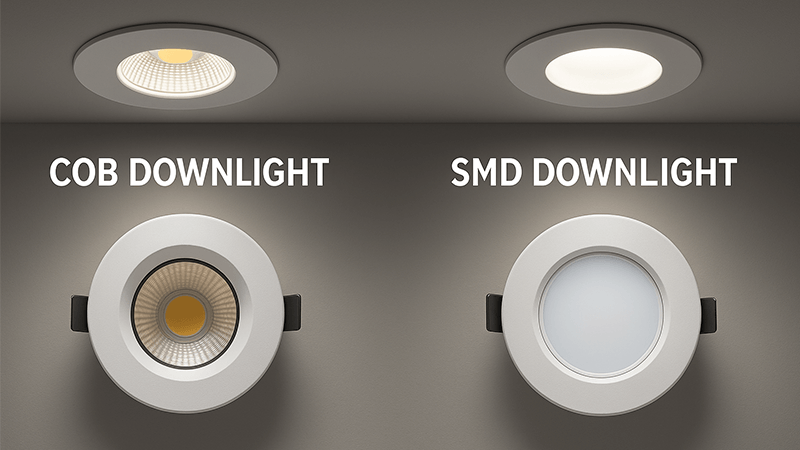

For downlights, the choice between SMD and COB depends on the application. COB is superior for high-intensity, single-shadow accent lighting9, while SMD is often more cost-effective for general, wide-angle ambient illumination.

There is no single "better" technology; there is only the better technology for the specific job. I've seen clients waste money putting expensive COB downlights in a hallway where a simple SMD fixture would have been sufficient. I've also seen them use SMD spotlights for retail displays, which created fuzzy, multiple shadows and made the products look cheap. The key is in matching the technology's strengths to your lighting goal.

Let's break down the core differences to help you make an informed decision for every lighting scenario you encounter.

Head-to-Head Comparison: COB vs. SMD in Downlights

| Feature | COB (Chip on Board) LED Downlight | SMD (Surface Mounted Device) LED Downlight |

|---|---|---|

| Light Source | A single, large LED module with many chips packed tightly together. | Multiple individual LED chips spread out on a circuit board. |

| Light Quality | Single, clean shadow. Resembles a traditional halogen light. | Multiple, softer shadows that can appear fuzzy at the edges. |

| Beam Control | Excellent. The small source size allows for precise control with reflectors and lenses for narrow, focused beams. | Good for wide flood beams, but harder to control for tight spotting. |

| Best Application | Accent lighting, high ceilings, retail displays, anywhere a single, powerful beam is needed. | General ambient lighting, wide-area illumination, standard-height ceilings. |

| Efficiency (lm/W) | Generally very high, but can generate significant centralized heat. | Also very high. Heat is spread over a larger area, making it easier to manage. |

| Cost | Typically higher due to the COB chip and the required precision optics and heat sink. | Generally more cost-effective, especially for general-purpose lighting. |

For Shaz and other purchasing managers, this table is your decision-making guide. When a project requires highlighting products in a luxury boutique, you know to source COB track lights to get that crisp, high-end look. When you need to illuminate a large office space evenly and on a budget, high-quality SMD downlights are the smarter, more economical choice. The goal is not to standardize on one technology, but to build a portfolio of reliable suppliers for both, allowing you to specify the perfect lighting solution for every need. Your expertise lies in knowing when to use each tool.

Conclusion

In summary, COB downlights achieve top-tier uniformity not from the chip alone, but from the complete fixture design. By understanding this, you can specify the perfect lighting solution for every application.

Explore the advantages of COB LED downlights for achieving uniform lighting in various applications. ↩

Understand the impact of lighting quality on mood, functionality, and aesthetics in interiors. ↩

Discover how COB technology enhances lighting quality and performance in various applications. ↩

Learn about the key factors to consider for selecting the right downlight fixtures for your needs. ↩

Learn about the importance of lighting uniformity and how it impacts visual comfort and aesthetics. ↩

Discover how lumen density affects the quality and intensity of light in different settings. ↩

Learn about the benefits of SMD LED technology for general lighting applications. ↩

Discover the steps to develop a comprehensive lighting plan that meets design and functional goals. ↩

Explore techniques for using accent lighting to create visual interest and depth in spaces. ↩