Struggling with retrofit jobs that demand high-quality light in old spaces? Old fixtures and wiring can be a headache. You need a reliable, modern solution that simplifies installation.

Contractors choose COB LED downlights for retrofits because they offer intense, high-quality light from a single point, just like classic halogens. This makes upgrading easy while delivering superior energy efficiency, a longer lifespan, and the clean, professional look that clients want.

I've worked in lighting manufacturing for years, and I've seen countless trends come and go. But the shift towards COB LED downlights1 for renovations isn't just a trend; it's a practical choice driven by real-world benefits. My clients, like Shaz, a purchasing manager in the UAE, consistently spec them for big projects. They know that when you're dealing with existing structures, you need a product that is both powerful and forgiving. So, what really sets these lights apart from all the other options on the market? Let's dive deeper and find out.

Are COB LEDs better?

Are you tired of the dotted, uneven light from some LED products? Do multiple shadows from a single fixture ruin the professional look you're trying to achieve? You need a cleaner light source.

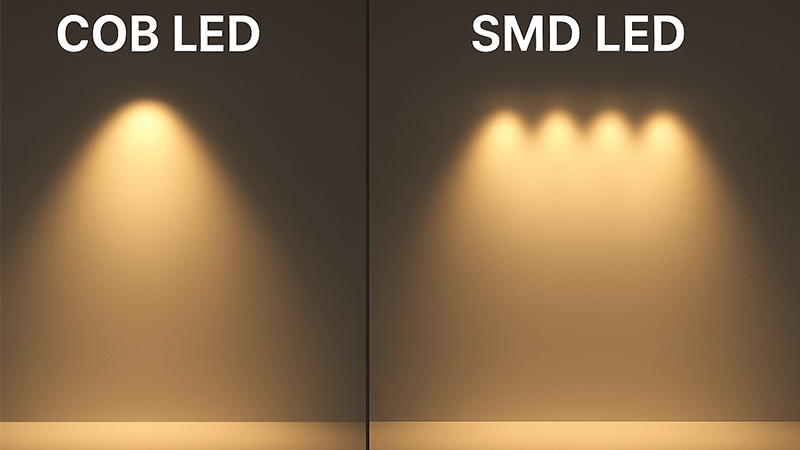

Yes, for applications needing focused, high-quality light2t](https://insights.acuitybrands.com/acuity-perspectives-blog/remember-lighting-quality-when-designing-efficiency-driven-retrofit-projects)%%%FOOTNOTE_REF_3%%%, COB (Chip-on-Board) LEDs are often better. They produce a powerful, uniform beam from a single point, eliminating the multiple shadows4 common with older SMD LEDs. This results in superior light quality and better thermal performance5.

When contractors are deciding between different types of LEDs, the conversation often comes down to COB versus SMD (Surface Mounted Device). From my experience on the factory floor, the choice depends entirely on the application, but for downlights, COB technology has some clear advantages that make it a winner for retrofit projects.

Light Quality and Uniformity

The biggest visual difference is the quality of the light itself. An SMD fixture uses many small, individual LED chips spread across a board. This can create multiple shadows and a "polka-dot" effect if the diffuser6 isn't perfect. A COB LED, on the other hand, packs all the chips into one small, tight module. This acts like a single, powerful point of light. The result is a clean, crisp beam with a single, soft shadow, very similar to the halogen lamps that contractors are often replacing. This makes the light feel more natural and high-end, which is a huge selling point for clients.

Efficiency and Thermal Management

The design of a COB LED isn't just for looks; it’s also highly practical. By mounting the chips directly onto a substrate, usually aluminum or ceramic, heat is pulled away from the source much more efficiently. In lighting, heat is the enemy of longevity and performance. Better heat dissipation7 means the LED will last longer and maintain its brightness and color consistency over its lifespan. For a contractor, this means fewer callbacks and more satisfied customers. Here’s a quick breakdown of how they compare:

| Feature | COB (Chip-on-Board) LED | SMD (Surface Mounted Device) LED |

|---|---|---|

| Light Source | Single, uniform point of light | Multiple, separate points of light |

| Shadows | Single, soft shadow | Multiple, sharp shadows |

| Lumen Density | Very high | Moderate |

| Heat Dissipation | Excellent, direct to heatsink | Good, but more complex path |

| Best For | Spotlights, downlights, high-bays | Strip lights, bulbs, area lighting |

What are the disadvantages of COB LED lights?

Worried that COB LEDs sound too good to be true? Every technology has trade-offs, and it's smart to know the potential downsides before committing to a large order.

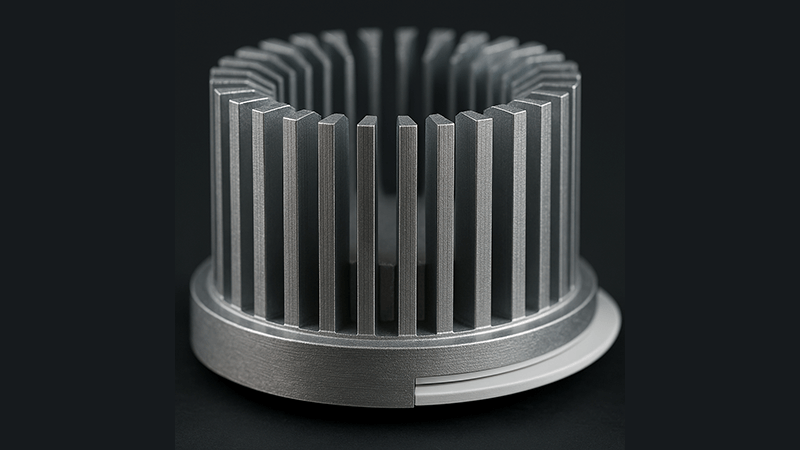

The primary disadvantages of COB LEDs are their high concentration of heat in a tiny area, which demands an excellent heatsink, and their fixed color output8. If the thermal management is poor, the light's lifespan will suffer dramatically. Quality manufacturing is key.

While I'm a big advocate for COB technology in downlights, I always advise my clients to be aware of its limitations. Nothing is perfect, and knowing where a product might fall short is just as important as knowing its strengths. The two biggest challenges with COB LEDs are heat and power sensitivity.

The Challenge of Intense Heat

Think of a COB LED as a tiny, super-bright engine. It creates a lot of power—and therefore a lot of heat—in a very small space. If that heat isn't drawn away quickly and effectively, the LED chip will degrade, losing brightness and shifting in color before failing completely. This is why the heatsink isn't just a piece of metal; it’s the most critical component for ensuring a long life. In my factory, we spend a huge amount of time engineering and testing our heatsinks to guarantee they can handle the thermal load. A cheap downlight often cuts corners here, and it’s the first thing to fail.

Sensitivity to Voltage Fluctuation

This is a technical point, but it's crucial for purchasing managers like Shaz who work in regions with variable power grids. From my factory testing, I've learned a critical lesson: a COB downlight must perform reliably even when the voltage isn't perfect. Under a standard 220V grid with a typical ±10% fluctuation, a quality COB product must maintain at least 95% of its luminous flux. If the driver and chip can't handle this, you will see noticeable flicker or changes in brightness. For a high-end commercial or residential project, this is simply unacceptable. It's a clear sign of a low-quality driver, and it's a detail we always focus on.

Fixed Color Output

The final disadvantage is less a flaw and more a characteristic of the design. A single COB module produces a single color of light. You can get them in warm white, cool white, or anything in between, but you can't change the color of that single chip. Unlike some SMD products that can combine red, green, and blue chips (RGB) for dynamic color-changing effects, a COB is built for a high-quality, single-color output. For 99% of retrofit downlight applications, this isn't an issue, but it is something to be aware of for specialized projects.

Are COB LED lights safe?

Worried about the safety of new lighting technology? Overheating, fire risk, and electrical issues are real concerns, and you need to ensure every product on your job site is safe.

Yes, COB LED lights are very safe when sourced from a reputable manufacturer that follows international standards. They operate on low-voltage DC power and are designed with robust heatsinks to prevent overheating. Always look for safety certifications9 like CE, RoHS, and UL.

Safety is the number one priority. It's a non-negotiable part of our manufacturing process, and it should be the first question a contractor or purchasing manager asks. Fortunately, COB LED technology, when implemented correctly, is one of the safest lighting options available. Its safety comes down to three key areas: electrical design, thermal management, and third-party verification.

Electrical Safety by Design

One of the core safety features is the LED driver. This device converts the high-voltage AC power from the wall (like 120V or 220V) into low-voltage DC power that the COB chip actually uses. This low-voltage operation significantly reduces the risk of electric shock during installation or maintenance compared to older lighting systems. Furthermore, in most downlight designs, the driver is a separate unit from the light engine. This physical separation helps keep the electronic components cooler and safer, as they are not housed directly next to the main heat source—the COB chip itself.

The Heatsink as a Safety Feature

We’ve discussed the heatsink's role in performance and longevity, but it's just as critical for safety. Its primary job is to keep the COB chip operating at a safe temperature, well below its maximum limit. A properly engineered heatsink ensures the fixture never gets hot enough to pose a fire risk or damage surrounding materials like wood, drywall, or ceiling insulation. When you hold a well-made COB downlight, you can feel the weight and see the fins of the heatsink. That's not just for show; that is a fundamental safety component at work.

Why Certifications Matter

For a purchasing manager like Shaz, seeing logos like CE or UL on a product sheet is more than just a formality. These certifications are proof that the product has been independently tested and verified to meet strict safety standards.

- CE: This marking indicates that the product complies with the health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- RoHS: This directive restricts the use of specific hazardous materials found in electrical and electronic products.

- UL/ETL: These are common certifications in North America that prove a product meets safety standards set by independent laboratories. As a manufacturer, we invest heavily in getting these certifications because they are our promise to you that our products are built to be safe and reliable.

Do COB LED lights need a diffuser?

Is the raw power of a COB LED creating uncomfortable glare? Are you aiming for a soft, ambient light rather than a harsh spotlight? The right optic makes all the difference.

While a COB LED can function without a diffuser, it's highly recommended to use one—or a lens—to control the light. The raw chip is intensely bright and can cause significant glare. An optic softens and distributes the beam for visual comfort and a professional finish.

A bare COB chip is an incredible piece of technology, but its raw light is almost too powerful for the human eye. It's like looking directly at the sun. For any practical application in a home or business, you need to control that light. This is done with optics—specifically, diffusers, reflectors10, and lenses. The choice between them depends entirely on the lighting effect you want to achieve.

Managing Glare with Lenses and Reflectors

The main goal of an optic is to reduce glare and shape the light beam. Glare is measured by a metric called UGR (Unified Glare Rating), and a low UGR is essential for comfortable spaces.

- Diffusers: A simple frosted or opal cover placed over the COB is a diffuser. It scatters the light in all directions, creating a very soft, even glow. This is great for general ambient lighting11, but it can reduce the overall punch and efficiency of the light.

- Reflectors: A polished or faceted cone around the COB chip is a reflector. It gathers the light and shapes it into a specific beam angle, like 60 degrees. Reflectors are great for creating a wide, even flood of light for general illumination.

- Lenses (TIR): A Total Internal Reflection (TIR) lens is the most advanced option. This is a small, precisely engineered plastic or glass optic that sits directly over the COB. It captures nearly all the light produced and directs it exactly where it’s needed with minimal spill. TIR lenses provide the best control over the beam and are excellent for creating focused accent lighting with very low glare.

| Optic Type | Primary Function | Best For |

|---|---|---|

| Diffuser | Softening light, reducing hotspots | General ambient lighting, wall washing |

| Reflector | Shaping light into a wider beam | General illumination in larger spaces |

| TIR Lens | Precise beam control, high efficiency | Accent lighting, retail displays, task lighting |

Matching the Optic to the Application

When a client like Shaz comes to me with project plans, we don't just talk about the downlight; we talk about the optics. For a hotel lobby, they might need a wide-beam reflector for general lighting. But for the hotel's art gallery, they would need a narrow-beam TIR lens12 to create dramatic highlights on the paintings. The versatility of COB downlights truly comes alive when you pair them with the right optic. It allows contractors to use the same base fixture to create many different lighting effects13, simplifying inventory and installation.

Conclusion

COB LED downlights offer a powerful combination of light quality, efficiency, and safety. This makes them the top choice for contractors tackling modern retrofit projects and satisfying their clients.

Explore the advantages of COB LED downlights, including energy efficiency and superior light quality for retrofitting projects. ↩

Understand the importance of focused lighting in creating visually appealing and functional spaces. ↩

Learn techniques to ensure high-quality lighting in retrofitting, enhancing aesthetics and functionality. ↩

Explore solutions to eliminate multiple shadows and achieve uniform lighting in your projects. ↩

Learn about the significance of thermal management in LED lighting and its impact on performance. ↩

Understand how diffusers enhance lighting quality and reduce glare in various applications. ↩

Understand the importance of heat dissipation in extending the life of LED lighting products. ↩

Explore the benefits and limitations of fixed color outputs in LED lighting applications. ↩

Find out which safety certifications ensure the reliability and safety of LED lighting products. ↩

Explore the role of reflectors in shaping light and enhancing illumination in spaces. ↩

Get insights into effective ambient lighting techniques that enhance comfort and aesthetics. ↩

Learn about TIR lenses and their advantages in achieving precise beam control in lighting. ↩

Discover how optics can transform lighting effects, allowing for versatile design solutions. ↩