Your lighting makes everything look washed out? This disappoints clients and hurts sales. The secret to vibrant, true colors lies in understanding the Color Rendering Index (CRI) for your lights.

CRI, or Color Rendering Index, is vital for COB LED downlights because it measures how accurately the light reveals the true colors of objects. High CRI lighting ensures that environments like retail stores, galleries, and homes appear natural and vibrant, directly impacting perception and satisfaction.

So, a high CRI number sounds great, but what does it really mean for your projects? It's more than just a number on a spec sheet; it's about creating the right atmosphere and ensuring everything under the light looks exactly as it should. Let's dig deeper into what CRI is and why it's so critical for you as a purchasing manager who values quality.

What is the purpose of the Color Rendering Index (CRI)?

Confused by datasheets packed with technical jargon? Picking a light source based on the wrong spec can make a beautiful space look lifeless. CRI gives you one simple metric for color quality1.

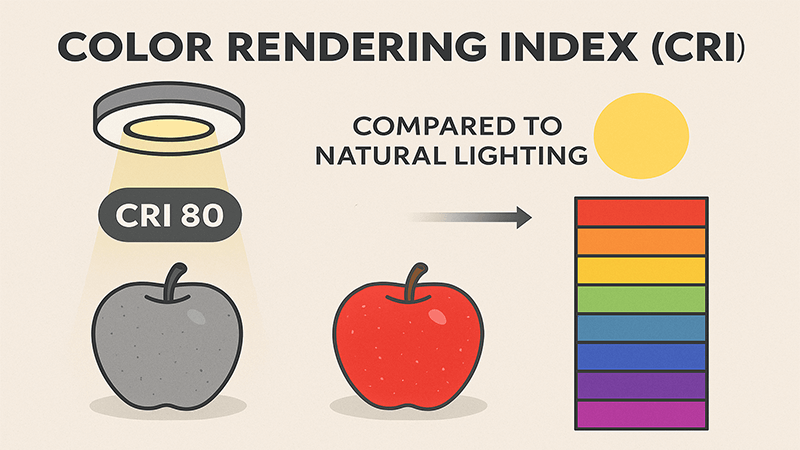

The main purpose of the Color Rendering Index (CRI)2 is to provide a quantitative measure of a light source's ability to faithfully reveal the colors of objects. It compares the appearance of eight standard pastel colors under a light source to their appearance under a perfect reference light.

I remember talking with Shaz, a purchasing manager from the UAE I've worked with for years. He told me that in his early days, he focused almost entirely on lumens and cost. He sourced lights for a high-end boutique, and while they were bright, the client complained that their expensive fabrics looked cheap and faded. That’s when he realized brightness means nothing if the colors are wrong. The purpose of CRI is to prevent this exact problem. It’s a tool to guarantee quality. Think of it as a guidepost for visual integrity3. Natural sunlight has a CRI of 100, which is our benchmark for perfect color. The CRI scale, from 0 to 100, tells you how close an artificial light source, like an LED, comes to this natural ideal. A low CRI light will distort colors, making them appear dull or shifted in hue. A high CRI light will render them accurately, making them look rich and natural. For any project where appearance is key—from retail displays to art galleries—CRI isn't just a number; it's a promise that what your client sees is real. It’s your quality assurance for color.

What is a good CRI value?

Are you specifying CRI 804 lights just because it's standard? This might be costing you client satisfaction in applications that demand better color. Prioritizing a higher CRI can set you apart.

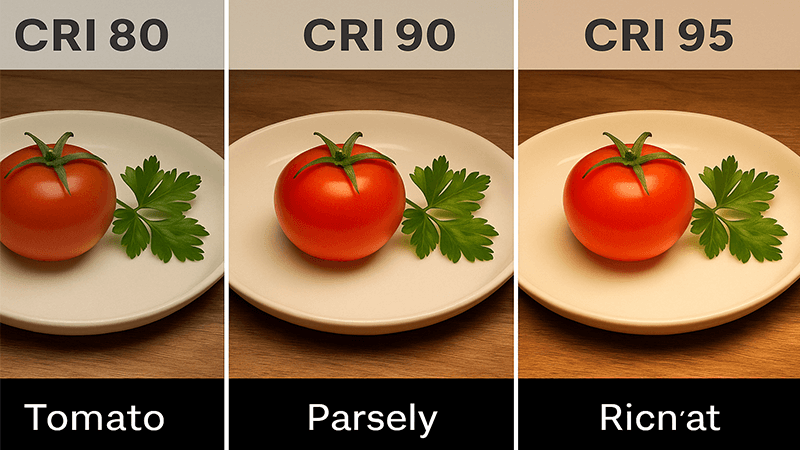

A CRI of 80 is generally considered the baseline for acceptable color rendering in most commercial spaces. However, for applications where color accuracy is critical, a CRI of 90 or above is a good value. For premium results, look for CRI 95 or even higher.

"Good" really depends on the application, but from my experience, the standard is shifting higher. A decade ago, CRI 80 was a big step up for LEDs. Today, I tell my partners like Shaz to consider CRI 905 as the new standard for quality projects. But here’s a crucial insight I learned on the factory floor: a high overall CRI score can be misleading. The standard CRI calculation, known as Ra, averages the scores of only eight pastel colors (R1-R8). It completely ignores saturated colors, including the most important one: strong red (R9).

Why does R9 matter so much? It's essential for accurately rendering skin tones, wooden furniture, and fresh food. A light can have a CRI of 90, but if its R9 value6 is low or even negative, people will look sickly, and rich cherry wood will appear dull brown. When sourcing high-quality LEDs, I always insist my clients ask for the R9 value.

Here's a breakdown to guide your decisions:

| CRI Value | R9 Value | Best Application |

|---|---|---|

| CRI 80+ | Typically low (<20) | General lighting for offices, warehouses, corridors where color isn't critical. |

| CRI 90+ | Should be >50 | Retail, hospitality, quality residential, museums. Essential for good visuals. |

| CRI 95+ | Should be >80 | High-end fashion retail, art galleries, medical examination rooms, print shops. |

For any serious project, don't just accept a "CRI 90" label. Ask your supplier for the full test report and check the R9 value. A good R9 value is your assurance of truly superior color quality.

What is the importance of CRI?

Do you find that your completed projects sometimes lack the "wow" factor? The lighting might be bright, but the space feels sterile and uninviting. This is often a sign of poor color rendering.

The importance of CRI lies in its direct impact on human perception, comfort, and behavior. High CRI lighting creates more visually appealing, vibrant, and natural-looking environments. This improves the customer experience7 in retail, enhances focus in offices, and makes homes feel more welcoming.

The importance of CRI goes far beyond making colors look pretty. It has a tangible impact on business and well-being. I've seen it firsthand. One of my clients, a supermarket chain, switched from standard CRI 80 to CRI 95 downlights8 in their produce section. They reported a measurable increase in sales of fresh fruits and vegetables. Why? Because under high CRI light, the reds of the apples were richer, the greens of the lettuce were crisper, and everything looked fresher and more appealing. This is a direct return on investment.

In a different context, consider a high-end hotel lobby. The goal is to make guests feel comfortable and luxurious. If the lighting has a low CRI, the expensive artwork on the walls looks flat, the rich textures of the furniture are lost, and even the skin tones of the guests and staff can look unnatural. This creates a subtle sense of unease. High CRI lighting brings the entire interior design to life, making the space feel warm, rich, and welcoming. It validates the designer's choices and enhances the guest's experience.

The impact can be broken down by industry:

- Retail: High CRI makes products more attractive, encouraging purchases. It is non-negotiable for fashion, furniture, and cosmetics.

- Hospitality: It creates a welcoming and luxurious atmosphere, improving guest satisfaction and perception of quality.

- Healthcare: In medical settings, accurate color rendering (especially high R9) is critical for diagnosis, from assessing skin conditions to analyzing samples.

- Art & Museums: High CRI ensures that artwork is seen exactly as the artist intended, preserving cultural integrity.

Ultimately, light is the medium through which we experience a space. CRI determines the quality of that experience. For a purchasing manager, choosing a high CRI fixture is not an expense; it's an investment in the success of the project.

What is CRI in downlights?

You specify downlights for a job, but are you considering how the fixture design affects color quality? Not all downlights deliver on the promise of the LED chip's CRI.

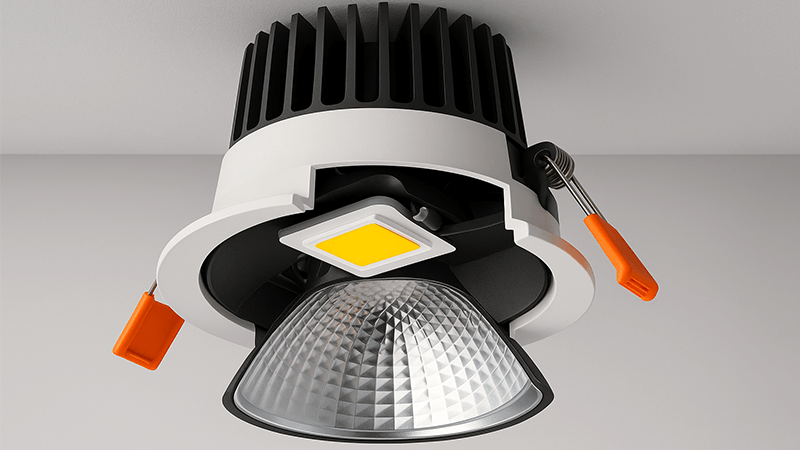

In downlights, CRI measures the color rendering capability9 of the entire fixture. This includes the COB LED chip, the reflector, the lens, and any diffusers. A well-designed downlight will maintain the high CRI of its light source, ensuring accurate color from the final output.

When we talk about CRI in downlights, we’re evaluating the complete system, not just the LED chip inside. This is a critical distinction that I always emphasize with my clients. A manufacturer might use a top-tier COB chip with a CRI of 97, but if they pair it with a poorly designed reflector or a cheap, low-transmittance lens, the light that actually exits the fixture could have a much lower effective CRI. The materials and coatings used in the optical components10 can selectively filter certain wavelengths of light, altering the final color rendering performance.

For example, I once analyzed a competitor's "high CRI" downlight. The COB chip was indeed good, but they used a plastic reflector with an imperfect coating. Our tests showed that the final output had a significantly lower R9 value than the chip's spec sheet promised. The fixture was literally stripping out some of the critical red spectrum. This is why at my company, iPHD, we focus on holistic design. Our reflectors use high-purity aluminum11 with multi-layer coatings12, and our lenses are made from optical-grade PMMA to ensure maximum light transmittance with minimal color distortion.

For a purchasing pro like Shaz, here’s what to look for:

- System-Level CRI: Don't just trust the chip's CRI. Ask for photometric data13 (an IES file or test report) for the entire downlight fixture.

- Optical Components: Inquire about the materials. Are the reflectors made of high-purity aluminum11 or cheap plastic? Are the lenses optical-grade?

- Consistency: Does the manufacturer have tight quality control14 to ensure every downlight in a batch performs identically?

A downlight is a precision instrument for delivering light. Its CRI performance is a measure of that precision. Choosing a well-engineered fixture guarantees that the high CRI you paid for is what your client actually gets.

Conclusion

In summary, understanding CRI, especially the R9 value, is not just a technical detail. It is essential for delivering quality lighting projects15 that create vibrant, true-to-life, and successful spaces16.

Understanding the factors that affect color quality can help you make informed decisions when selecting lighting solutions. ↩

Understanding CRI is crucial for achieving accurate color representation in lighting, enhancing visual appeal and client satisfaction. ↩

Exploring visual integrity can help you understand the impact of lighting on the overall aesthetic and functionality of a space. ↩

Exploring the adequacy of CRI 80 can help you determine if your lighting meets the necessary standards for color accuracy. ↩

Understanding the shift to CRI 90 can help you elevate your lighting projects and meet modern quality expectations. ↩

R9 value is critical for accurately rendering skin tones and vibrant colors, making it essential for quality lighting. ↩

Understanding the impact of lighting on customer experience can help you design more effective retail environments. ↩

Choosing the right downlights is crucial for achieving desired lighting effects and ensuring color accuracy. ↩

Understanding color rendering capability is essential for selecting lighting that accurately represents colors in various settings. ↩

Exploring the impact of optical components can help you understand how to achieve optimal lighting quality. ↩

High-purity aluminum enhances light quality and efficiency, making it a superior choice for lighting applications. ↩

Exploring the benefits of multi-layer coatings can help you understand their role in enhancing light quality and durability. ↩

Understanding photometric data is essential for evaluating lighting performance and ensuring quality in your projects. ↩

Quality control ensures consistent performance in lighting products, which is vital for meeting client expectations. ↩

Understanding the key considerations can help you deliver lighting projects that meet client needs and enhance spaces. ↩

Exploring the elements of successful spaces can guide you in designing lighting that enhances functionality and aesthetics. ↩