Choosing the right lighting can feel like a compromise. You want maximum protection but also need to keep project costs down. This often leads to over-specifying, which can hurt your budget.

The most direct answer is that IP44 downlights are a smart, cost-effective alternative to IP65 because they provide ample protection for most common indoor damp locations. They are designed for areas with moisture and splashes, not direct water jets, making IP65 an unnecessary expense in many situations.

As someone who has spent years in the lighting manufacturing industry, I have seen countless projects where money was wasted on over-specified products. The key to successful and profitable lighting procurement1 is not always choosing the highest number. It is about deeply understanding the application and matching the product perfectly to the environment. This knowledge is what separates a good purchasing manager from a great one. Getting this right saves money, ensures safety, and delivers long-lasting quality for your clients.

Let's break down the details that will help you make more informed decisions and strengthen your position as a sourcing expert.

Are IP65 downlights energy efficient?

You see a high IP rating2 and assume it means a better light overall. But what if the heavy sealing needed for IP653 traps heat, shortening the LED's life and hurting its efficiency?

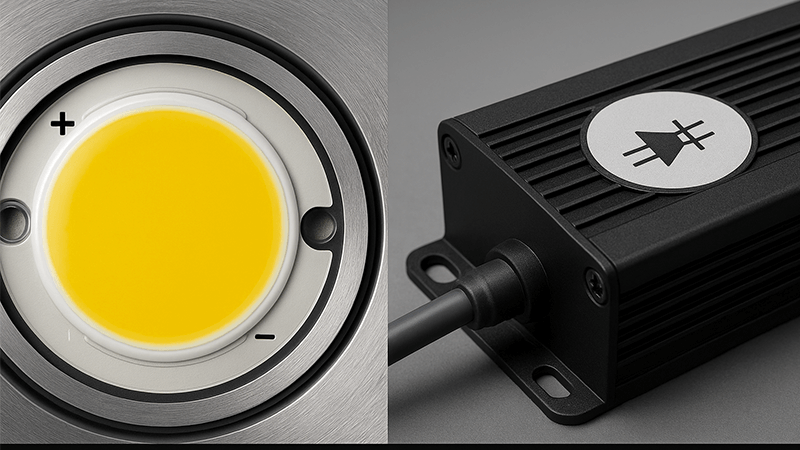

Yes, IP65 downlights can be very energy-efficient, but the IP rating itself has no direct link to efficiency. A downlight's energy efficiency4 comes from its LED chip, driver, and thermal management system. In a poorly designed fixture, the sealing for IP65 can even reduce efficiency by trapping heat.

When sourcing downlights, it is crucial to separate the concept of ingress protection (IP) from energy performance. An IP rating tells you how well a fixture is sealed against dust and water. Energy efficiency, on the other hand, is measured in lumens per watt (lm/W) and is determined by the quality of the internal components. I’ve seen this mistake made many times. A client insists on IP65 fixtures for an entire office building, including dry hallways and meeting rooms. The assumption is that "more protection is better." However, the real story is in the heat management. An LED's biggest enemies are heat and moisture. An IP65 rating solves for moisture, but if the design doesn't also solve for heat, you have a big problem. A tightly sealed unit with a poor heatsink becomes a tiny oven for the LED chip5. This trapped heat will cause the LED's light output to decrease much faster—a phenomenon we call lumen depreciation6—and can lead to premature failure. In some cases, a well-designed IP447 fixture with a superior heatsink will outperform and outlast a poorly designed IP65 fixture in a dry environment.

Is IP Rating Related to Energy Efficiency?

No, they are independent characteristics. One is about sealing, the other is about performance.

| Factors Defining Energy Efficiency | Factors Defining IP Rating |

|---|---|

| LED Chip Technology (lm/W) | First Digit: Solids Protection (e.g., dust) |

| Driver Efficiency (%) | Second Digit: Liquids Protection (e.g., water) |

| Thermal Management (Heatsink Design) | Gasket Material and Compression |

| Optical Design (Lens/Reflector) | Sealant Application and Curing |

From my factory floor experience, the best manufacturers treat these as separate but related engineering challenges. We build a high-efficiency light engine first, then we design the housing around it to meet the required IP rating without compromising thermal performance. When you review a product, ask the supplier about their heatsink design8, not just the IP test report.

What are the most energy efficient downlights?

Trying to find the most efficient downlight can be confusing with all the different numbers. If you only look at wattage, you might buy a product that uses more power for less light.

The most energy-efficient downlights9 are simply those with the highest lumens-per-watt (lm/W) rating. To find them, you should look for products that specify high-quality LED chips, high-efficiency drivers10 (over 90%), and a well-engineered thermal management system to keep the components cool.

As a manufacturer, I can tell you that true efficiency is a result of a balanced system. It is not about one single component. When my team and I develop a new downlight at iPHD, we focus on a few key areas to maximize performance. First is the light source itself. We select LED chips from top-tier brands that offer the highest lumens per watt. Second is the driver. The driver converts AC power to the DC power the LED needs, and some energy is lost as heat in this process. A low-quality driver might be 80% efficient, meaning 20% of the energy is wasted. We use drivers that are over 90% or even 95% efficient, which saves energy and also produces less heat inside the fixture. Finally, and most critically, is thermal management11. We design our aluminum heatsinks to have the maximum possible surface area to draw heat away from the LED chip and dissipate it into the air. A cooler LED is a more efficient and longer-lasting LED. So, when you are comparing products, don't just look at the wattage. Ask for the lm/W value.

Key Metrics for Downlight Efficiency

Here's how you can easily compare two potential products. The one with the highest lm/W offers the best value and performance.

| Feature | Downlight A (Highly Efficient) | Downlight B (Standard Efficiency) |

|---|---|---|

| Power Consumption | 8W | 10W |

| Light Output (Lumens) | 960 lm | 900 lm |

| Lumens per Watt (lm/W) | 120 lm/W | 90 lm/W |

| Driver Efficiency | 92% | 85% |

| Heatsink Material | Die-cast Aluminum, large fins | Stamped Aluminum, small fins |

In this example, Downlight A uses 20% less energy but produces more light. This is the kind of detail that makes a sourcing manager truly valuable to their company.

Is IP44 ok for heavy rain?

You're looking at a product marked "water-resistant12" and wonder if it is strong enough for outdoor use. Using an IP44 light in direct rain could cause failure, short circuits, and expensive problems.

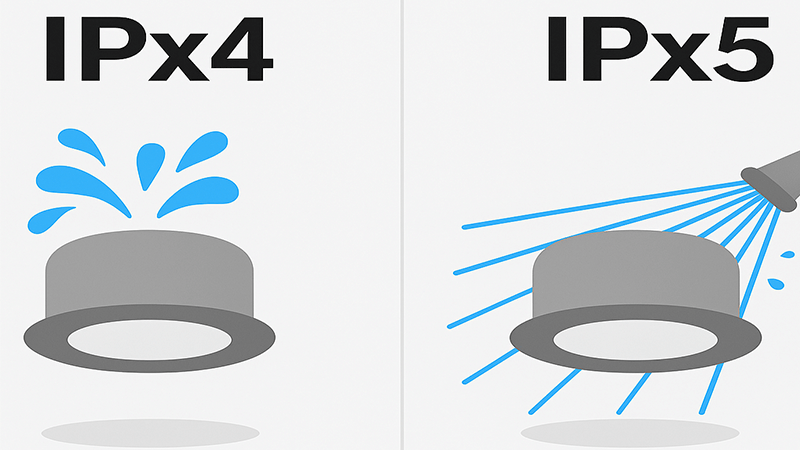

No, IP44 is not okay for direct exposure to heavy rain. The '4' in IP44 means it is protected against splashing water from any direction, but not powerful jets or immersion. It is suitable for bathrooms or covered outdoor areas, but for direct rain exposure, you need at least IP65.

This is one of the most common and costly misunderstandings I see in lighting specifications. The numbers in an IP rating have very specific meanings, and mixing them up can lead to system failure. The first digit refers to protection against solids (like dust), and the second digit refers to protection against liquids. For a purchasing manager like you, Shaz, understanding the second digit is key to saving money. Imagine a large hotel project. The downlights under the covered main entrance porch will only ever get hit by misty, wind-blown spray. This is a perfect example of "splashing water13." Using an IP44 downlight here is completely safe and much more cost-effective14 than using an IP65. Now, think about a light in a planter in the open-air garden. That fixture will be hit by direct, heavy downpours, which is like a "low-pressure jet" of water. That location absolutely requires an IP65 fixture. By carefully mapping the right IP rating to each specific location, you can reduce the overall cost of the lighting package significantly without taking any risks.

Decoding IP Ratings: The Numbers Explained

Let's focus on the second digit, which is all about water protection.

| Second Digit | Protection Against Water | Common Use Case Example |

|---|---|---|

| 4 | Splashing water from any direction. | Bathrooms (Zone 2), kitchens, covered building eaves, protected porches. |

| 5 | Low-pressure jets of water from any direction. | Exposed outdoor walls, decks, gardens, areas that are hosed down for cleaning. |

| 6 | High-pressure jets of water from any direction. | Industrial wash-down areas, decks on ships, areas cleaned with pressure washers. |

Over-specifying is safe, but it is not smart business. True expertise lies in specifying correctly. Using IP44 where appropriate is a classic value engineering move that demonstrates your deep knowledge of the products and their application.

Are IP44 lights double insulated15?

You need to ensure every fixture is electrically safe, especially in damp places. But it is easy to confuse a light's water resistance with its electrical safety16 features, which could lead to non-compliance.

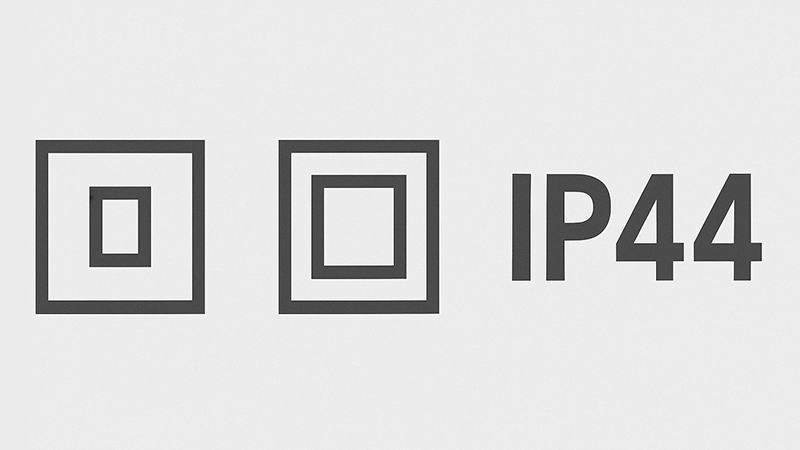

Not always. An IP44 rating and double insulation (Class II) are two separate safety standards. IP rating protects against water ingress, while double insulation protects against electric shock. An IP44 light can be Class I (requiring an earth wire) or Class II (no earth needed).

This is another critical detail that experienced buyers must pay attention to. You cannot assume one type of protection implies another. They serve two entirely different purposes. The IP rating is about keeping things like dust and water out of the fixture's housing. The Electrical Insulation Class is about what happens inside the fixture to protect users from electric shock if a fault occurs. In many of my early dealings with clients, I had to explain this difference. For example, during a renovation of an older building, the electrical wiring might not have a reliable protective earth connection. In this situation, for a bathroom, you must use a Class II17 (double insulated) fixture. It has two layers of insulation, so no single fault can result in a dangerous voltage on the outside of the fitting. Just choosing an IP44 light is not enough; if it is a Class I fixture, it would be unsafe to install without an earth connection. As a sourcing expert, you must check both specifications on the product data sheet.

IP Rating vs. Electrical Class: Two Different Protections

These two systems work together to ensure a light is safe, but they are not interchangeable.

| Electrical Class | Symbol | Description | Safety Feature |

|---|---|---|---|

| Class I | Earth Symbol | The fixture has basic insulation, and the metal casing is connected to a protective earth wire. | A fault current is safely directed to the ground, tripping the circuit breaker. |

| Class II | Square within a Square | Also called "double insulated." It has basic plus supplementary insulation. No earth wire is needed. | The design prevents any single fault from allowing live parts to touch the outer casing. |

| Class III | III in a Diamond | The fixture is powered by a Separated Extra-Low Voltage (SELV) supply (typically 12V or 24V). | The voltage is too low to cause a dangerous electric shock. |

When you request a quote from a supplier, make sure your request specifies both the required IP rating and the electrical class. This shows a high level of professionalism and ensures you receive a product that is not just suitable, but fully compliant and safe for its intended location.

Conclusion

Ultimately, choosing between IP44 and IP65 is not about which is better, but which is right for the job. By matching the IP rating to the specific environment, you ensure safety while optimizing project costs.

Explore best practices for efficient and effective lighting procurement strategies. ↩

Get insights into how IP ratings determine the protection level of lighting fixtures. ↩

Learn when IP65 downlights are necessary for optimal protection in various environments. ↩

Understand the key metrics for evaluating energy efficiency in lighting products. ↩

Learn about the characteristics of high-quality LED chips for better lighting efficiency. ↩

Discover the factors that lead to lumen depreciation and how to avoid them. ↩

Understand the ideal applications for IP44 lighting to ensure safety and efficiency. ↩

Learn how heatsink design influences the performance and lifespan of LED fixtures. ↩

Discover the top energy-efficient downlights to maximize your lighting performance. ↩

Understand the role of high-efficiency drivers in reducing energy consumption. ↩

Find out how effective thermal management can enhance LED performance and longevity. ↩

Explore the distinctions between water-resistant and waterproof lighting options. ↩

Discover how splashing water affects the choice of lighting in various environments. ↩

Find tips on selecting cost-effective lighting options without compromising quality. ↩

Learn about the safety features of double insulated lighting fixtures. ↩

Learn essential tips for ensuring electrical safety in your lighting projects. ↩

Understand the significance of Class II insulation for electrical safety in fixtures. ↩